Woodworking is a craft that has been around for centuries, with artisans using various techniques to create stunning pieces of furniture and decorative items. In recent years, there has been a growing trend of combining wood with metal to create unique and visually appealing designs. One of the key components of this trend is the use of metal base supports, which not only add durability to the woodwork but also enhance its aesthetic appeal.

When it comes to woodworking, durability is an important factor to consider. The use of metal base supports provides stability and strength to the wooden piece, ensuring that it can withstand the test of time. Whether it’s a coffee table or a bookshelf, the addition of metal base supports ensures that the piece remains sturdy and functional for years to come.

However, metal base supports are not just about functionality. They also add a touch of beauty to the woodwork. The combination of wood and metal creates a visual contrast that is both striking and elegant. The metal base supports can be designed in various shapes and styles, allowing artisans to create unique and eye-catching designs. Whether it’s a sleek and modern design or a rustic and vintage-inspired piece, the use of metal base supports adds a touch of sophistication to the finished product.

Woodworking with metal base supports is a perfect example of combining durability and beauty. By incorporating metal into their designs, artisans can create pieces that are not only functional but also visually appealing. Whether you’re a woodworking enthusiast or someone looking to add a unique piece of furniture to your home, consider the use of metal base supports to elevate your woodworking projects to the next level.

Why choose metal base supports for woodworking projects

Woodworking projects require a strong and stable base support structure to ensure durability and longevity. While traditional wooden bases can offer stability, an alternative option that combines both durability and beauty is to use metal base supports.

Here are some reasons why you should consider using metal base supports for your woodworking projects:

- Strength: Metal base supports provide exceptional strength and stability, making them ideal for supporting heavy wooden structures. They can withstand the weight of large tabletops, shelves, and even entire furniture pieces with ease.

- Durability: Unlike wood, metal is not susceptible to rot, warping, or cracking. This means that metal base supports will remain sturdy and intact over time, ensuring the longevity of your woodworking projects.

- Versatility: Metal base supports come in a variety of styles, finishes, and designs, allowing you to choose the perfect match for your woodworking project. Whether you prefer a sleek and modern look or a rustic and industrial aesthetic, there is a metal base support that will complement your design.

- Ease of installation: Metal base supports are generally easy to install, requiring minimal tools and expertise. Many metal base supports come with pre-drilled holes or adjustable brackets, making the installation process straightforward and hassle-free.

- Support for various woodworking applications: Metal base supports are not limited to specific woodworking projects. They can be used for a wide range of applications, including tables, benches, shelves, and even cabinetry. Their versatility makes them a go-to choice for woodworkers of all skill levels.

- Enhanced aesthetic appeal: Metal base supports can add a touch of elegance and sophistication to your woodworking projects. Their sleek and shiny finish can beautifully contrast with the warmth and natural grain of wood, creating a visually striking and balanced look.

In conclusion, using metal base supports for your woodworking projects can provide numerous benefits, including strength, durability, versatility, ease of installation, support for various applications, and enhanced aesthetic appeal. Consider incorporating metal base supports into your next woodworking project to achieve both beauty and durability.

Benefits of using metal base supports

Metal base supports offer several benefits when it comes to woodworking projects. Whether you are constructing furniture or creating decorative pieces, incorporating metal base supports can enhance both the durability and aesthetic appeal of your work. Here are some key advantages of using metal base supports:

- Strength and stability: Metal is known for its strength and durability. By using metal base supports, you can ensure that your woodworking projects have a sturdy and stable foundation. This is especially important for items like tables and chairs that need to withstand heavy use.

- Design flexibility: Metal base supports come in various shapes and sizes, offering a wide range of design possibilities. Whether you prefer a sleek and minimalist look or a more intricate design, metal bases can be customized to suit your aesthetic preferences.

- Longevity: Compared to other materials, metal base supports have a longer lifespan. They are resistant to rotting, warping, and cracking, making them ideal for outdoor furniture and other items exposed to the elements.

- Easy maintenance: Metal base supports are relatively easy to clean and maintain. They can be wiped down with a damp cloth or cleaned with mild soap and water. Additionally, metal surfaces are less likely to accumulate dirt, dust, and grime, making them a practical choice for high-traffic areas.

- Compatibility with other materials: Metal base supports can be used in combination with various materials, such as wood, glass, or stone. This allows for creative and unique design combinations, resulting in visually stunning pieces.

Overall, incorporating metal base supports into your woodworking projects provides numerous advantages. From increased durability to design flexibility, metal bases offer a reliable and attractive foundation for your creations. Whether you’re a professional woodworker or a hobbyist, using metal base supports can take your woodworking to the next level.

How metal base supports enhance durability

One of the key benefits of using metal base supports in woodworking projects is the enhanced durability they provide. By incorporating metal into the construction of the base supports, the overall strength and stability of the piece can be significantly improved.

Metal base supports are commonly used in furniture making, particularly for tables, chairs, and shelving units. These supports are typically made from materials such as steel or iron, which are known for their toughness and resistance to wear and tear.

When combined with wood, metal base supports create a robust foundation that can withstand heavy loads and constant use. The metal components provide added structural support, preventing the piece from warping or collapsing over time.

In addition to their strength, metal base supports also offer excellent stability. The sturdy nature of metal ensures that the furniture remains steady on uneven surfaces, preventing wobbling and increasing safety.

Furthermore, metal is highly resistant to moisture, humidity, and pests, making it an ideal choice for outdoor or high-moisture environments. Unlike wood, metal does not crack, rot, or attract insects, ensuring the longevity of the piece.

In terms of maintenance, metal base supports are relatively easy to clean and care for. Unlike wooden supports, which may require regular staining or sealing, metal supports only need occasional wiping to remove dirt and dust. This makes them a practical option for those who prefer low-maintenance furniture.

Another advantage of using metal base supports is their aesthetic appeal. The combination of metal and wood creates a visually striking contrast that adds beauty and character to the furniture. This blend of different materials can complement various interior styles, from modern to rustic.

In summary, incorporating metal base supports in woodworking projects enhances durability in several ways. Metal provides increased strength, stability, and resistance to moisture and pests, ensuring the longevity of the piece. Additionally, metal base supports offer easy maintenance and add aesthetic appeal to the furniture.

Creating aesthetic appeal with metal base supports

When it comes to woodworking, incorporating metal base supports can add a touch of modernity and elegance to your project. Whether you are building a coffee table, dining table, or even a desk, using metal base supports can create a visually pleasing contrast and enhance the overall aesthetic appeal.

One way to create aesthetic appeal with metal base supports is by choosing a unique design. There are numerous options available, ranging from minimalist and geometric designs to more intricate and ornate patterns. By selecting a design that complements the style of your woodwork, you can achieve a harmonious and visually compelling piece.

Furthermore, consider the material and finish of the metal base supports. Stainless steel, brass, and wrought iron are popular choices due to their durability and ability to withstand the test of time. Additionally, these metals can be finished in various ways, such as polished, brushed, or even powder-coated, allowing you to further customize the appearance to match your woodworking project.

Incorporating metal base supports can also provide stability and strength to your furniture. Woodworking pieces, such as tables, often require a sturdy base to withstand regular use and weight. Metal base supports can fulfill this requirement while simultaneously adding an industrial and modern touch to the design.

Another advantage of using metal base supports is their versatility. While they are commonly used in contemporary and modern designs, they can also be successfully incorporated into rustic or traditional woodworking projects. The combination of wood and metal creates an interesting visual contrast that can enhance the overall appeal of your furniture.

When designing your woodworking project with metal base supports, consider the size and proportion of the base. A well-balanced design ensures that the metal supports enhance the overall aesthetic without overshadowing the beauty of the woodwork. Carefully analyze the dimensions of your furniture and choose metal supports that complement the piece while providing ample stability.

In conclusion, adding metal base supports to your woodworking projects can elevate the aesthetic appeal and create a stunning visual impact. By carefully selecting a unique design, considering the material and finish, and ensuring the size and proportion are well-balanced, you can create a piece that seamlessly combines durability and beauty.

Woodworking techniques for integrating metal base supports

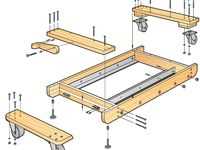

When it comes to woodworking projects with metal base supports, there are several techniques that can be used to ensure a strong and durable joint between the wood and metal components. These techniques include:

- Pre-drilling pilot holes: Before attaching the metal base supports to the wood, it is important to pre-drill pilot holes to prevent the wood from splitting. This is especially important when working with hardwoods.

- Using screws or bolts: Depending on the specific project, screws or bolts can be used to secure the metal base supports to the wood. Screws are often used for lighter-duty applications, while bolts provide added strength and stability for heavier loads.

- Using appropriate hardware: When choosing hardware for attaching the metal base supports, it is important to select the appropriate size and type for the specific project. This includes considering factors such as load capacity and corrosion resistance.

- Using adhesive: In addition to hardware, adhesive can also be used to enhance the bond between the wood and metal. Epoxy or polyurethane adhesives are commonly used for this purpose, as they provide a strong and durable bond.

- Reinforcing with metal brackets or plates: For added reinforcement, metal brackets or plates can be used to connect the wood and metal components. These can be attached using screws or bolts to provide additional strength.

- Sealing and finishing: After the metal base supports have been integrated into the woodworking project, it is important to seal and finish the wood to protect it from moisture and enhance its appearance. This can be done using a variety of finishes, such as varnish or lacquer.

By employing these techniques, woodworkers can ensure that their projects with metal base supports not only look beautiful, but also stand the test of time.

Selecting the right metal base supports for your project

When it comes to woodworking projects with a metal base support, selecting the right type of metal is crucial to ensure both durability and aesthetics. Here are some factors to consider when choosing the metal base supports for your project:

- Strength: The metal base support should be strong enough to support the weight of the wood and any additional items placed on it. Look for metals such as steel or iron that offer high strength and stability.

- Corrosion resistance: Depending on the environment where your project will be placed, it’s important to choose a metal that is corrosion resistant. Stainless steel is a popular choice as it is resistant to rust and can withstand moisture.

- Appearance: The metal base support should complement the overall design and aesthetics of your woodworking project. Consider the color, texture, and finish of the metal to ensure it enhances the beauty of the wood.

- Cost: Budget is always a factor to consider when selecting metal base supports. Some metals, such as brass or copper, may be more expensive than others. Evaluate your budget and choose a metal that meets both your financial and project requirements.

- Customizability: If you have specific design requirements or want to add a personal touch to your project, look for metal base supports that can be customized or fabricated to your specifications. This allows you to create a unique piece that perfectly fits your vision.

Conclusion: The right metal base supports can elevate your woodworking project to a new level of durability and beauty. By considering factors such as strength, corrosion resistance, appearance, cost, and customizability, you can select the perfect metal base supports that will not only provide stability but also enhance the overall aesthetics of your creation.

Care and maintenance of metal base supports

Metal base supports are durable and strong, but they still require proper care and maintenance to ensure their longevity and continued beauty. Here are some tips to help you take care of your metal base supports:

- Clean regularly: Dust and dirt can accumulate on the surface of metal base supports, so it is important to clean them regularly. Use a soft, lint-free cloth to gently wipe away any debris. Avoid using abrasive cleaners or scrubbing tools that can scratch the metal.

- Avoid moisture: Metal base supports can rust if exposed to moisture for prolonged periods. To prevent this, make sure to keep them dry and avoid placing wet items directly on the metal surface. If the metal does get wet, wipe it dry immediately.

- Protect from scratches: Metal base supports can be prone to scratches, especially if they come into contact with hard or sharp objects. Use coasters or protective mats under items that can potentially scratch the surface. Avoid dragging heavy or sharp objects across the metal.

- Inspect for damages: Regularly inspect your metal base supports for any signs of damage, such as dents or loose joints. Address any issues promptly to prevent further damage and ensure the stability of the supports. If necessary, consult a professional for repair or replacement.

- Apply protective coating: To further enhance the durability of your metal base supports, consider applying a protective coating. This can help prevent oxidation and maintain the appearance of the metal. Be sure to follow the manufacturer’s instructions for proper application.

By following these care and maintenance tips, you can prolong the lifespan of your metal base supports and keep them looking beautiful for years to come.

FAQ:

What are some advantages of using metal base supports in woodworking?

Using metal base supports in woodworking offers several advantages. Firstly, metal base supports provide durability and stability to the furniture piece, ensuring its longevity. Secondly, metal base supports can add a modern and sleek look to the overall design, enhancing the aesthetic appeal. Additionally, metal base supports can be customized in different shapes and finishes to match the desired style of the furniture piece. Lastly, metal base supports offer great weight-bearing capacity, making them suitable for heavy furniture items.

What types of metal are commonly used for base supports in woodworking?

In woodworking, different types of metal can be used for base supports. One popular choice is steel, known for its strength and durability. Steel can be given different finishes, such as brushed, polished, or powder-coated, to match the desired look. Another commonly used metal is aluminum, which is lightweight yet strong. Aluminum base supports are often used in modern and contemporary designs. Other metals like iron and brass can also be used depending on the specific design and requirements.

How are metal base supports attached to wooden furniture?

Metal base supports can be attached to wooden furniture through various methods. One common method is using screws or bolts to secure the metal base to the wooden structure. The screws or bolts are typically inserted through pre-drilled holes in the metal and then tightened into the wood. Another method is using metal brackets or brackets with adjustable legs specifically designed for attaching metal bases. These brackets are screwed or bolted to the wood, providing a sturdy connection between the metal base and the wooden furniture.

Can metal base supports be used for all types of woodworking projects?

Metal base supports can be used for a wide range of woodworking projects, but their suitability may depend on several factors. In general, metal base supports are suitable for most furniture pieces, including tables, chairs, desks, and shelves. However, for certain delicate or intricate pieces, such as fine antique furniture or intricate wooden carvings, metal base supports may not be the best choice as they can detract from the overall aesthetic. It is important to consider the specific design, style, and function of the woodworking project when deciding whether to use metal base supports.

Do metal base supports require any maintenance?

Metal base supports generally require minimal to no maintenance. However, depending on the type of metal used and its finish, some maintenance may be necessary. For example, steel base supports with a brushed or polished finish may require occasional polishing to maintain their shine. Powder-coated metal base supports may need to be wiped clean with a damp cloth. It is also important to regularly inspect the metal base supports for any signs of rust or corrosion and address these issues promptly to ensure their longevity and functionality.

Can metal base supports be customized to match the specific design requirements?

Yes, metal base supports can be customized to match the specific design requirements of the woodworking project. Metal base supports can be fabricated in different shapes, sizes, and finishes, allowing for a high degree of customization. Whether the design calls for a sleek and minimalistic base or a more ornate and decorative one, metal base supports can be tailored to meet those requirements. Customization options also include selecting the type of metal, such as steel, aluminum, or brass, and choosing finishes like brushed, polished, or powder-coated.