Woodworking is an age-old craft that requires precision, skill, and the right tools. One versatile tool that has been widely used for centuries is the dowel. Dowels are cylindrical rods that are used for joining two pieces of wood together. They come in various sizes and materials, making them a versatile option for different applications.

Dowels offer several advantages over other joining methods. Firstly, they provide a strong and sturdy connection between pieces of wood. When properly inserted into pre-drilled holes, dowels create a tight bond that can withstand significant weight and pressure. This makes them an excellent choice for building structures that need to be durable and long-lasting.

In addition to their strength, dowels are also known for their versatility. They can be used in a wide variety of woodworking projects, from simple furniture repairs to complex cabinetry. Dowels can be easily cut, sanded, and shaped to fit any design or dimension, making them ideal for creating intricate and detailed joinery. Whether you’re constructing a chair, table, or bookshelf, dowels can provide a seamless and professional finish to your project.

Another advantage of using dowels is the aesthetic appeal they bring to woodworking. Unlike screws or nails, which can leave unsightly marks or damage to the wood, dowels create a clean and polished look. They can be completely hidden or left partially visible, depending on the design preference. This makes dowels a popular choice for furniture makers who value both functionality and beauty in their creations.

Benefits of Using Dowels for Joinery

When it comes to creating sturdy structures, dowels are an essential tool for joinery. They offer several benefits that make them a popular choice among woodworkers:

- Strength: Dowels provide strong and reliable joints that can withstand heavy loads. When properly installed, they create a solid connection that can hold up to stress and movement.

- Versatility: Dowels can be used in a wide range of woodworking projects. They can join different wood species together, as well as other materials such as metal or plastic.

- Easy to Use: Using dowels for joinery is relatively simple. With the right tools and techniques, woodworkers can create precise and accurate joints without the need for complex machinery or intricate joinery skills.

- Cost-Effective: Dowels are an affordable option for joinery. Compared to other types of joinery, such as mortise and tenon or dovetail joints, dowels are more accessible and require fewer tools.

- Disassembly and Repair: One of the advantages of using dowels for joinery is that they allow for easy disassembly and repair. If a joint becomes damaged or needs to be altered, it is possible to remove the dowels, make the necessary adjustments, and reassemble the structure.

- Hidden Joints: Dowels can be used to create visually appealing joint designs. Since dowels are inserted into holes, they can be sanded flush with the surface, creating seamless and hidden connections that enhance the aesthetics of the finished piece.

- Resistance to Movement: Dowels have good resistance to movement caused by wood expansion and contraction. This makes them suitable for projects where stability is essential, such as furniture or cabinetry.

Overall, dowels offer a practical and efficient solution for joinery. Their strength, versatility, ease of use, cost-effectiveness, and other benefits make them a valuable addition to any woodworking project.

Overview of Dowel Joinery Techniques

Dowel joinery offers a versatile and sturdy method for creating various structures and furniture pieces. It involves using cylindrical wooden pegs, known as dowels, to connect and reinforce joints. There are several dowel joinery techniques that are commonly used in woodworking, each with its own advantages and applications.

1. Butt Joint with Dowels

The butt joint with dowels is a simple yet effective technique that involves joining two pieces of wood end-to-end. To create this joint, holes are drilled into both pieces of wood where they intersect, and dowels are inserted into these holes. The dowels provide additional strength and alignment to the joint.

2. Edge-to-Edge Joint with Dowels

The edge-to-edge joint with dowels is used to join two pieces of wood along their edges. Similar to the butt joint, holes are drilled into the edges of the two pieces of wood, and dowels are inserted into these holes to hold the pieces together. This technique is commonly used in tabletop construction and panel assemblies.

3. Miter Joint with Dowels

The miter joint with dowels is a technique used to join two pieces of wood at a 45-degree angle. This joint is commonly used in frame construction, such as picture frames or mirror frames. Dowels are inserted into holes drilled at the mitered edges of the wood pieces, providing strength and stability to the joint.

4. Laminated Dowel Joint

The laminated dowel joint involves joining multiple layers or laminations of wood to create a thicker and stronger piece. This technique is often used in the construction of tabletops and countertops. Dowels are inserted into holes drilled through the laminations, creating a tight and durable joint.

5. Dowel Reinforced Mortise and Tenon Joint

The dowel reinforced mortise and tenon joint combines the strength and precision of the traditional mortise and tenon joint with dowels for added reinforcement. Dowels are inserted into holes drilled through both the mortise and tenon parts of the joint, ensuring a secure and long-lasting connection.

6. Dowel Corner Reinforcement

Dowel corner reinforcement is a technique used to strengthen and reinforce the corners of wooden structures. Dowels are inserted diagonally into the corner joints, providing additional support and preventing the structure from coming apart under stress or load.

These are just a few of the many dowel joinery techniques available in woodworking. Each technique offers its own advantages and can be used in various applications, allowing for creative and sturdy construction of wooden structures and furniture pieces.

Choosing the Right Dowels for Your Woodworking Projects

When it comes to woodworking projects, choosing the right dowels is crucial for achieving sturdy and durable structures. Dowels are small cylindrical rods that are used to reinforce joints and provide extra strength to wood connections. With a variety of dowel types available, it’s important to understand the different options and select the ones that best suit your specific woodworking needs.

1. Material:

Dowels are typically made from wood or metal, each offering its own set of advantages. Wooden dowels are commonly used in woodworking due to their ease of use and ability to blend in with the overall wood structure. Metal dowels, on the other hand, provide exceptional strength and are often used in heavy-duty applications or where extra reinforcement is required.

2. Size:

The size of the dowel is an important factor to consider. The diameter of the dowel determines its strength and load-carrying capacity. Thicker dowels are generally stronger, but they can be more difficult to work with and may require larger holes. Thinner dowels, on the other hand, are more flexible and can be used for lighter applications.

3. Length:

The length of the dowel should be chosen based on the specific woodworking project. Ideally, the dowel should be long enough to provide sufficient reinforcement for the joint. It’s important to measure the depth of the hole and add extra length to ensure a secure connection.

4. Type:

There are several types of dowels available, including plain, fluted, and spiral. Plain dowels are the most common and are suitable for most woodworking projects. Fluted dowels have ridges along their length, which provide extra grip and prevent rotation. Spiral dowels have a helical shape, allowing them to be screwed into the wood, providing a strong and secure connection.

5. Joinery Technique:

Consider the type of joinery technique you plan to use when choosing dowels. Dowels can be used for various joints, such as butt joints, miter joints, and edge joints. The type of joint will determine the location and number of dowels required, as well as the size and material best suited for the joint.

6. Quality:

Finally, it’s important to choose dowels of high quality to ensure a reliable and durable structure. Look for dowels that are straight, without any cracks or defects. The surface should be smooth and free from rough edges or imperfections that could affect the strength of the joint.

By carefully considering the material, size, length, type, joinery technique, and quality of dowels, you can make informed decisions that will result in strong and long-lasting woodworking connections. Remember to always follow proper woodworking techniques and consult with experts if needed to ensure the success of your woodworking projects.

Different Types of Dowels and Their Uses

When it comes to woodworking with dowels, there are several types of dowels to choose from, each with its own unique characteristics and uses. Here are some of the most common types of dowels and their applications:

- Wooden Dowels: Wooden dowels are the most traditional and commonly used type of dowels. They are made from solid wood and come in various diameters and lengths. These dowels are versatile and suitable for a wide range of applications, including furniture construction, cabinetry, and general woodworking projects.

- Metal Dowels: Metal dowels, such as steel or aluminum dowels, are known for their strength and durability. They are often used in heavy-duty applications where extra support and stability are required. Metal dowels are commonly used in construction projects, industrial settings, and for reinforcing joints.

- Plastic Dowels: Plastic dowels are lightweight and resistant to moisture and chemicals, making them suitable for outdoor applications or projects that require exposure to water or other corrosive substances. They are commonly used in garden furniture, decking, and marine applications.

- Joining Dowels: Joining dowels, also known as biscuit dowels, are special types of dowels that are used for joining pieces of wood together. They are often used in conjunction with biscuits, which are small, flat ovals made from compressed wood. Joining dowels are commonly used in cabinetmaking, panel construction, and other projects where a strong, concealed joint is required.

- Fluted Dowels: Fluted dowels are dowels with spiral grooves along their length. These grooves provide extra grip and increase the bond strength between the dowel and the surrounding material. Fluted dowels are commonly used in furniture making, especially for joining chair legs and arms to seats or backrests.

Choosing the right dowel for your woodworking project depends on several factors, such as the desired strength, aesthetic appeal, and environmental conditions the project will be exposed to. It’s important to consider these factors and select the appropriate type of dowel to ensure a sturdy and long-lasting structure.

Factors to Consider When Selecting Dowels

When selecting dowels for woodworking projects, there are several important factors to consider. The right choice of dowel can make a significant difference in the strength and durability of your joinery. Here are some key considerations:

- Size: The size of the dowel is an essential factor to consider. You’ll need to choose a dowel size that matches the thickness and width of the wood you are joining. A dowel that is too thin may not provide enough strength, while a dowel that is too thick may cause splitting or other issues.

- Material: Dowels can be made from a variety of materials, including wood, metal, and plastic. The material you choose will depend on your specific needs and preferences. Wood dowels are commonly used for woodworking projects because they can be easily matched to the wood being joined and provide a natural appearance.

- Strength: The strength of the dowel is another crucial factor to consider. The dowel should be able to withstand the load and stresses that will be placed on the joint. If you are working with heavy loads or high-stress situations, you may want to consider using a larger or stronger dowel.

- Length: The length of the dowel will depend on the depth of the hole and the thickness of the materials being joined. The dowel should be long enough to provide sufficient anchorage and support, but not so long that it protrudes excessively.

- Surface Texture: The surface texture of the dowel can also affect the strength and stability of the joint. A smooth dowel may provide less grip and may be more prone to slipping. On the other hand, a textured or grooved dowel can enhance the grip and provide a stronger bond.

- Cost: The cost of the dowel is another consideration. While wood dowels are generally more affordable, materials like metal and plastic may be more expensive. Consider your budget and the specific needs of your project when making a selection.

By carefully considering these factors, you can choose the right dowel for your woodworking projects, ensuring strong and sturdy joinery that will stand the test of time.

Tools and Equipment Required for Dowel Joinery

Dowel joinery is a versatile technique that requires a few specific tools and equipment. Here are the essential items you’ll need to get started with dowel joinery:

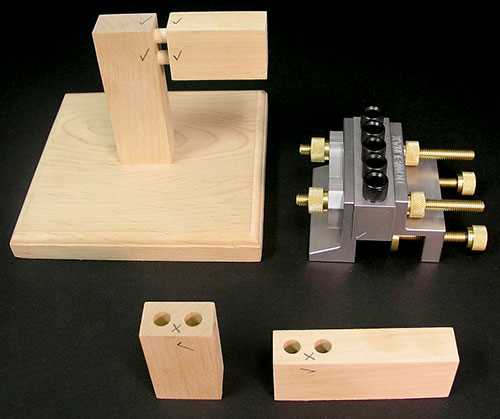

- Dowel Jig: A dowel jig is a tool used to guide the drill bit and create precise holes for the dowels. It ensures accurate alignment and spacing of the dowels.

- Power Drill: A power drill is necessary for drilling the dowel holes. It should have adjustable speed settings and a depth stop to control the depth of the holes.

- Wooden Dowels: Dowels are cylindrical wooden rods that are inserted into the holes to join the pieces of wood together. They come in various diameters and lengths, so choose the appropriate size for your project.

- Sandpaper: Sandpaper is essential for smoothing the wooden surfaces before joining them. It helps to remove any rough spots or imperfections and ensures a tight and secure fit.

- Clamps: Clamps are used to hold the pieces of wood together while the glue dries. They provide pressure and ensure a strong bond between the dowels and the wood.

- Wood Glue: Wood glue is used to secure the dowels in the holes and create a strong joint. Choose a high-quality wood glue that dries clear and is suitable for indoor or outdoor use, depending on your project.

- Mallet or Hammer: A mallet or hammer is used to tap the dowels into the holes and ensure a snug fit. It helps to create a tight joint and eliminate any gaps between the dowels and the wood.

Having these tools and equipment on hand will make dowel joinery easier and more efficient. Remember to always wear appropriate safety gear, such as protective goggles and gloves, when working with power tools.

Essential Tools for Working with Dowels

When working with dowels for woodworking projects, it’s important to have the right tools on hand to ensure precise joinery and sturdy structures. Here are some essential tools to consider:

- Dowel Jig: A dowel jig is a tool that helps align drill holes for dowels. It provides accuracy and consistency in creating dowel joints.

- Hand Saw or Mitre Saw: A hand saw or mitre saw is used to cut dowels to the desired length. It is important to have a clean, straight cut to ensure a tight fit.

- Drill: A drill is necessary for creating holes in the wood to insert the dowels. It is recommended to use a drill with a drill stop for consistent depth.

- Clamps: Clamps are essential for holding pieces together while drilling and gluing. They help ensure a snug fit and prevent movement during the joining process.

- Sanding Block: A sanding block is useful for smoothing the surface of the wood and removing any rough edges or imperfections.

- Glue: Wood glue is an important adhesive for securing the dowels in the drilled holes. It is recommended to use a strong, waterproof glue for maximum durability.

- Chisel: A chisel can be used to clean up any excess glue or wood that may protrude from the dowel joints. It helps create a neat and finished appearance.

Having these essential tools will make working with dowels much easier and ensure strong, reliable joinery for your woodworking projects. Remember to always follow proper safety precautions and take your time to achieve the best results.

Safety Precautions for Using Dowel Joinery Tools

Woodworking with dowel joinery tools can be a rewarding and efficient way to create sturdy structures. However, it is important to prioritize safety when using these tools to prevent accidents and injuries. Here are some safety precautions to keep in mind:

- Wear protective gear: Always wear safety glasses to protect your eyes from flying debris. It is also recommended to wear a dust mask to prevent inhalation of dust particles.

- Use clamps: Secure your workpiece with clamps when using dowel joinery tools to ensure stability and reduce the risk of accidents.

- Keep a clean work area: Clear your work area of clutter and make sure it is well-lit. This will help you avoid accidents and injuries.

- Follow the manufacturer’s instructions: Read and understand the instructions provided by the manufacturer of your dowel joinery tools. Follow all safety guidelines and recommendations.

- Inspect your tools: Regularly inspect your dowel joinery tools for any damage or wear. Replace any worn-out or damaged parts to ensure safe operation.

- Keep your hands away from the cutting area: Always keep your hands away from the cutting area when using dowel joinery tools. Use push sticks or other safety devices to guide the workpiece and keep your hands at a safe distance.

- Take breaks: Woodworking can be physically demanding. Take regular breaks to rest and prevent fatigue, which can increase the risk of accidents.

Following these safety precautions will help you work with dowel joinery tools in a safe and efficient manner. Remember to prioritize safety at all times to prevent accidents and injuries.

Techniques for Creating Strong Dowel Joints

Creating strong dowel joints is essential for ensuring the stability and durability of woodworking projects. Here are some techniques you can use to create strong dowel joints:

- Accurate marking: Before drilling holes for dowels, it is crucial to accurately mark the positions on both pieces of wood. Use a marking gauge or measuring tools to ensure precise measurements.

- Drilling pilot holes: To ensure a precise fit, drill pilot holes for the dowels using a drill bit that matches the size of the dowel. The pilot holes should be slightly deeper than the length of the dowels to allow for glue.

- Using dowel centers: Dowel centers can help align the holes on one piece of wood with the corresponding holes on another piece. Insert the center into one hole, align the pieces, and tap the centers to leave marks on the second piece.

- Applying glue: Apply an adequate amount of woodworking glue to both the holes and the dowels. Spread the glue evenly with a brush or dowel, ensuring full coverage inside the holes.

- Inserting dowels: Insert the dowels into the pilot holes, making sure they are fully seated. Use a small mallet or hammer to tap them in if necessary. Wipe off any excess glue that may squeeze out.

- Clamping the joint: Once the dowels are inserted, use clamps to apply pressure and ensure a tight bond. Place clamps across the joint, alternating between top and bottom, and tighten them gradually.

- Cleaning excess glue: While the glue is still wet, clean any excess glue with a damp cloth or sponge. This will help prevent glue stains and ensure a clean finish.

- Allowing for drying time: Give the glue sufficient time to dry and cure according to the manufacturer’s instructions. Avoid putting stress on the joint during this time to allow for a strong bond.

By following these techniques, you can create strong and durable dowel joints that will provide stability and longevity to your woodworking projects.

Basic Steps for Creating Dowel Joints

Creating strong and durable connections with dowel joints is a straightforward process that can be accomplished with the following basic steps:

- Marking: Start by marking the locations on the two pieces of wood where you want to create the dowel joints. Measure and mark the points carefully to ensure accuracy.

- Drilling: Use a drill to create holes in each of the marked locations on the wood pieces. The diameter of the drill bit should match the diameter of the dowels you are using.

- Inserting Dowels: Apply wood glue to the inside of the drilled holes and on the dowels. Insert the dowels into one piece of wood, making sure they are fully inserted and aligned with the corresponding holes in the other piece of wood.

- Clamping: Use clamps to hold the two pieces of wood together firmly, ensuring that the dowels are tightly seated in the holes. Allow the glue to dry according to the manufacturer’s instructions.

- Trimming: Once the glue has dried, trim any protruding dowels using a saw or chisel, ensuring the joint is flush and smooth.

- Sanding: Sand the joint to smooth out any rough edges or inconsistencies, resulting in a seamless finish.

Dowel joints provide a reliable and versatile method of joining two pieces of wood together. By following these basic steps, you can create strong and sturdy structures that will stand the test of time.

FAQ:

What are dowels used for in woodworking?

Dowels are commonly used in woodworking to create sturdy joints between different pieces of wood. They are often used to reinforce the connections in furniture, cabinets, and other wooden structures.

How do you use dowels to join wood together?

To join wood together using dowels, you first drill matching holes in the two pieces of wood you want to connect. Then, you insert the dowels into the holes, apply glue to the dowels, and join the pieces of wood together. The dowels provide added strength and stability to the joint.

What are the advantages of using dowels for joinery?

Using dowels for joinery offers several advantages. Firstly, dowels create strong and durable joints that can withstand heavy loads and stress. Secondly, dowels provide alignment and precision during assembly, ensuring that the pieces of wood are correctly positioned. Lastly, dowels are a versatile and cost-effective solution for joinery, as they can be easily made at home or purchased in different sizes from hardware stores.

Can dowels be used for both decorative and functional purposes?

Yes, dowels can be used for both decorative and functional purposes in woodworking. Functionally, dowels provide structural support and reinforcement to joints, making them ideal for building sturdy and durable wooden structures. Decoratively, dowels can be used to create interesting patterns and designs on the surface of furniture, cabinets, and other wooden objects.

What types of wood are best suited for dowel joinery?

Several types of hardwood, such as oak, maple, and beech, are commonly used for dowel joinery. These hardwoods are known for their strength, durability, and resistance to wear and tear. However, softer woods like pine and poplar can also be used for dowel joinery, especially for less load-bearing applications.