Woodworking can be a complex and time-consuming skill to master. Whether you’re a seasoned professional or a beginner, there are always challenges that come with each new project. One of the most effective ways to simplify these complex tasks is by using woodworking jigs and fixtures. These are specialized tools and devices that are designed to help you perform specific tasks with greater accuracy and efficiency.

Woodworking jigs and fixtures are essentially guides or templates that hold your workpiece in a specific position, allowing you to make precise cuts or perform intricate operations. They can be used for a variety of tasks, such as cutting dadoes, routing mortises, creating box joints, and more. By using jigs and fixtures, you can eliminate the need for multiple measurements and calculations, reducing the chances of making mistakes and wasting materials.

One of the key advantages of using woodworking jigs and fixtures is that they enable you to replicate the same cuts or operations multiple times with consistent results. This is especially useful when you need to create multiple identical pieces for a project, such as drawer fronts or cabinet doors. With a well-designed jig or fixture, you can easily set up your workpiece and repeat the same action as many times as you need, ensuring that each piece is cut or shaped exactly the same way.

Not only do woodworking jigs and fixtures simplify complex tasks, but they also enhance safety in the workshop. By securely holding your workpiece in place, they reduce the risk of accidents and injuries that can occur when working with power tools. Moreover, they provide stability and support, allowing you to work with confidence and precision. Whether you’re a professional woodworker or a hobbyist, investing in quality jigs and fixtures can greatly improve your woodworking experience and help you achieve professional-level results.

Advantages of Using Woodworking Jigs and Fixtures

Woodworking jigs and fixtures are essential tools for any woodworker. They have numerous advantages and can greatly simplify complex tasks. Here are some of the benefits of using woodworking jigs and fixtures:

- Increased Accuracy: Jigs and fixtures provide precise measurements and guide the woodworker in making accurate cuts, holes, and joints. This helps in achieving consistent results with minimal errors.

- Time-saving: By using jigs and fixtures, woodworkers can streamline their workflow and save time. These tools eliminate the need for repetitive measurements and allow for quick and efficient work.

- Enhanced Safety: Jigs and fixtures hold the workpiece securely in place, reducing the risk of accidents or injuries. They provide stability and prevent slippage during cutting or shaping operations.

- Versatility: Woodworking jigs and fixtures can be customized to suit different projects and applications. They can be designed for specific angles, shapes, or sizes, making them versatile tools for various woodworking tasks.

- Consistency: Using jigs and fixtures ensures consistent results across multiple pieces. Once the jig or fixture is set up correctly, it can be used repeatedly to produce identical cuts or joints, eliminating variations in the final product.

- Increased Efficiency: Jigs and fixtures enable woodworkers to work more efficiently by eliminating the need for trial and error. They provide a pre-determined template or guide, allowing for faster and more accurate production.

- Improved Precision: Woodworking jigs and fixtures enable woodworkers to achieve intricate and complex designs that would otherwise be difficult to accomplish. They provide a stable platform for precision work, such as inlays or intricate joinery.

Overall, woodworking jigs and fixtures are indispensable tools that simplify complex tasks, increase efficiency, and improve the quality of woodworking projects. They are essential for both beginners and experienced woodworkers, enabling them to achieve professional and accurate results.

Types of Woodworking Jigs and Fixtures

Woodworking jigs and fixtures are tools that help simplify complex tasks in woodworking, providing accuracy and efficiency. There are various types of jigs and fixtures available for different woodworking projects.

- Joinery Jigs: Joinery jigs are used to assist in creating strong and precise joints in woodworking projects. Some common types of joinery jigs include dovetail jigs, box joint jigs, and mortise and tenon jigs.

- Routing Jigs: Routing jigs are designed to hold and guide a router, enabling precise and consistent cuts. Examples of routing jigs include edge guides, circle cutting jigs, and dado jigs.

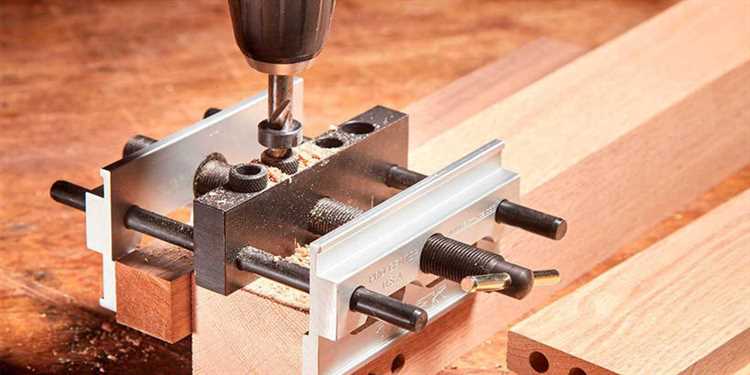

- Drilling Jigs: Drilling jigs are used to ensure accurate and consistent drilling of holes. They can include benchtop jigs, doweling jigs, pocket hole jigs, and hinge jigs, among others.

- Sanding Jigs: Sanding jigs are designed to hold and stabilize workpieces during sanding, making the process more efficient and achieving smoother finishes. Examples include sanding blocks, sanding sleds, and disc sanding jigs.

- Cutting Jigs: Cutting jigs are used to guide the cutting process, ensuring precise and consistent cuts. Some common cutting jigs include crosscut sleds, miter sleds, and taper jigs.

- Assembly and Clamping Jigs: Assembly and clamping jigs are used to hold and align workpieces during the assembly process, ensuring accurate and secure jointing. Examples include pocket hole jigs, biscuit joiners, and box clamps.

- Templates and Patterns: Templates and patterns are not technically jigs or fixtures, but they are commonly used in woodworking. They serve as guides for shaping and replicating specific designs and shapes.

These are just a few examples of the types of woodworking jigs and fixtures available. Each type has its own specific function and can greatly simplify complex tasks, making woodworking projects more efficient and accurate.

Choosing the Right Jigs and Fixtures for Your Project

Woodworking jigs and fixtures are incredibly useful tools that can simplify complex tasks and improve the accuracy of your woodworking projects. With the right jigs and fixtures, you can achieve more consistent results and save time and effort in the process. Here are some tips on choosing the right jigs and fixtures for your project:

- Understand your project requirements: Before selecting a jig or fixture, it’s important to understand the specific requirements of your project. Consider factors such as the type of joints you’ll be making, the size and shape of the workpieces, and any specific challenges or constraints you may face.

- Research available options: Once you have a clear idea of your project requirements, research the various jigs and fixtures available in the market. Look for options that are designed to address the specific needs of your project and can provide the desired level of precision and accuracy.

- Consider versatility: Some jigs and fixtures are designed for specific tasks or joints, while others offer more versatility. Depending on the scope of your woodworking projects, you may prefer a versatile jig or fixture that can be adapted to different applications.

- Look for user-friendly features: Ease of use is an important factor to consider when choosing jigs and fixtures. Look for features such as adjustable components, clear instructions, and user-friendly controls that can help you set up and use the jig or fixture effectively.

- Check for durability: Jigs and fixtures should be made of high-quality materials that can withstand the demands of woodworking tasks. Look for options that are sturdy, well-constructed, and built to last.

- Consider budget and value for money: While it’s important to choose a jig or fixture that meets your project requirements, it’s also important to consider your budget. Compare prices and evaluate the overall value for money, considering factors such as durability, versatility, and performance.

Remember, the right jigs and fixtures can significantly enhance your woodworking experience and help you achieve superior results. Take the time to evaluate your project requirements, research available options, and choose the jigs and fixtures that best fit your needs.

How to Build Custom Jigs and Fixtures

Building custom jigs and fixtures is a great way to simplify complex woodworking tasks and increase your efficiency in the workshop. By creating your own specialized tools, you can ensure that your work is accurate and consistent, and you may even discover new techniques or tricks along the way.

Here is a step-by-step guide on how to build custom jigs and fixtures:

- Identify the Task: Start by identifying the specific woodworking tasks that you find challenging or time-consuming. Jigs and fixtures are most useful for tasks that need to be repeated frequently or require precision.

- Plan Your Design: Once you have identified the task, sketch out your design for the jig or fixture. Consider the dimensions, materials, and any additional features or adjustments that may be necessary.

- Gather Materials: Collect all the necessary materials and tools for your project. This may include wood, screws, nuts, bolts, and any other hardware that is required.

- Measure and Cut: Use your design plans to measure and cut the necessary pieces of wood or other materials. Take your time to ensure accuracy, as any mistakes at this stage can affect the functionality of the jig or fixture.

- Assemble the Pieces: Begin assembling the various components of your jig or fixture, following your design plans. Use clamps or other fasteners to hold the pieces together securely.

- Add Adjustments: Depending on the specific task, you may need to add adjustments to your jig or fixture. This could include sliding tracks, adjustable stops, or other mechanisms that allow you to modify the tool to suit different needs.

- Test and Refine: Once your jig or fixture is assembled, test it out with a few practice runs. Pay attention to any issues or areas that can be improved. Make any necessary adjustments and refinements to ensure optimal performance.

- Use and Maintain: Once your custom jig or fixture is complete, integrate it into your woodworking workflow. Keep it well-maintained and clean, and make any repairs or adjustments as needed.

Remember, building custom jigs and fixtures is an ongoing process. As you gain experience and encounter new woodworking challenges, you can continue to refine and expand your collection of specialized tools. Happy woodworking!

Tips and Techniques for Using Woodworking Jigs and Fixtures

Woodworking jigs and fixtures are essential tools that can help simplify complex woodworking tasks. Whether you are a beginner or an experienced woodworker, using jigs and fixtures can improve your accuracy, save time, and enhance your overall woodworking experience. Here are some tips and techniques to make the most out of your woodworking jigs and fixtures:

- Choose the Right Jig or Fixture: There are a variety of jigs and fixtures available for different woodworking tasks. Make sure to select the right jig or fixture that is suitable for your specific needs. Consider factors such as the type of project, the material being used, and your skill level.

- Read and Follow Instructions: Before using any jig or fixture, it is important to thoroughly read and understand the instructions provided by the manufacturer. Following the instructions will ensure that you are using the tool correctly and safely.

- Secure the Jig or Fixture: Always make sure to securely attach the jig or fixture to your workbench or work surface. This will prevent any movement or slippage during the woodworking process, improving accuracy and safety.

- Measure and Mark: Use measuring tools such as rulers, squares, and calipers to accurately measure and mark your workpiece. This will ensure precise and consistent results when using jigs and fixtures.

- Practice and Test: Before using a jig or fixture on your actual project, it is advisable to practice and test it on a scrap piece of wood. This will allow you to get familiar with the tool and make any necessary adjustments or modifications.

- Maintain and Clean: Regularly maintain and clean your jigs and fixtures to keep them in good working condition. Remove any sawdust, debris, or build-up that may affect their functionality.

- Experiment and Innovate: While jigs and fixtures are designed for specific tasks, don’t be afraid to experiment and innovate. Sometimes, a slight modification or adjustment to a jig or fixture can yield better or unique results.

**

Common Mistakes to Avoid when Using Jigs and Fixtures

**

Woodworking jigs and fixtures can greatly simplify complex tasks and improve the accuracy of your woodworking projects. However, using jigs and fixtures incorrectly can lead to mistakes and compromise the quality of your work. To ensure successful results, it is important to avoid these common mistakes:

- Not following the instructions: Each jig or fixture comes with specific instructions on how to use it correctly. It is important to carefully read and understand these instructions before using the jig or fixture. Ignoring or misunderstanding the instructions can lead to improper usage and inaccurate results.

- Using the wrong size or type of material: Jigs and fixtures are often designed for specific sizes and types of materials. Using the wrong size or type of material can lead to improper functioning of the jig or fixture and produce inaccurate or compromised results. Always ensure that the material being used is compatible with the jig or fixture.

- Not securing the workpiece properly: One of the most common mistakes when using jigs and fixtures is not properly securing the workpiece. Failing to secure the workpiece tightly can result in movement or shifting, leading to inaccurate cuts or measurements. Always ensure that the workpiece is securely clamped or fastened to the jig or fixture.

- Forgetting to account for the thickness of the jig or fixture: Jigs and fixtures have a certain thickness, and failing to account for this can lead to inaccurate measurements or cuts. When using a jig or fixture, it is important to measure and mark the appropriate distance, taking into consideration the thickness of the jig or fixture itself.

- Not practicing and testing: Before using a jig or fixture on an actual project, it is important to practice and test it on scrap or test pieces. This allows you to familiarize yourself with the jig or fixture and ensure that it is functioning correctly. It also provides an opportunity to make any necessary adjustments or modifications before using it on the actual project.

Avoiding these common mistakes when using woodworking jigs and fixtures can help you achieve accurate and efficient results in your woodworking projects. Remember to always carefully read the instructions, use the correct size and type of material, secure the workpiece properly, account for the thickness of the jig or fixture, and practice and test before using on the actual project.

Enhancing Safety with Woodworking Jigs and Fixtures

Woodworking can be a rewarding and creative hobby, but it also carries inherent risks. Accidental injuries can occur if proper safety precautions are not followed. One effective way to enhance safety in woodworking is by using jigs and fixtures.

Jigs and fixtures are devices that are designed to hold, guide, or support a workpiece during woodworking operations. They provide stability and accuracy, reducing the risk of accidents and injuries. Here are some ways in which jigs and fixtures enhance safety:

- Improved control: When using a jig or fixture, the workpiece is securely held in place, allowing the woodworker to have better control over the tool. This reduces the chances of the workpiece slipping or being mishandled, preventing accidents.

- Consistent positioning: Jigs and fixtures ensure that the workpiece is positioned consistently, eliminating the need for manual adjustments. This minimizes the chances of incorrect positioning, which can lead to accidents or errors in the woodworking process.

- No hands near the tool: By using a jig or fixture, woodworkers can keep their hands at a safe distance from the cutting tool. This greatly reduces the risk of accidental contact with the tool, preventing potential injuries.

- Reduced kickback: Kickback, which occurs when a piece of wood is propelled back towards the operator, can be dangerous. Jigs and fixtures can help reduce the likelihood of kickback by providing support and preventing the workpiece from getting caught or trapped.

In addition to these safety benefits, jigs and fixtures also improve the overall quality of woodworking projects. They enable precise and repeatable cuts, resulting in more accurate and professional-looking pieces.

Examples of common woodworking jigs and fixtures include crosscut sleds, miter gauges, featherboards, and router tables. These tools can be purchased or built by woodworkers based on their specific needs and projects.

| Tool | Description |

|---|---|

| Crosscut sled | A jig used for making accurate crosscuts on a table saw. |

| Miter gauge | A device used to guide workpieces at precise angles for miter cuts. |

| Featherboard | A fixture that applies pressure to the workpiece, keeping it against a fence or table, preventing movement during cutting. |

| Router table | A table with a mounted router, providing stability and control for routing operations. |

It is important to remember that while jigs and fixtures enhance safety, they are not a substitute for personal protective equipment (PPE) such as safety glasses, ear protection, and dust masks. Woodworkers should always wear appropriate PPE and follow safe working practices.

In conclusion, jigs and fixtures play a crucial role in enhancing safety in woodworking. By providing stability, control, and consistency, they reduce the risk of accidents and injuries. Woodworkers should make use of these tools to not only ensure their safety but also improve the quality of their woodworking projects.

Examples of Projects Simplified with Jigs and Fixtures

Woodworking jigs and fixtures are invaluable tools that can simplify complex tasks and improve the accuracy and efficiency of various woodworking projects. Here are a few examples of projects that can be simplified with the use of jigs and fixtures:

-

Box joints: Creating perfect box joints can be challenging without the use of jigs and fixtures. A box joint jig ensures precise cuts and consistent spacing between the fingers, resulting in a clean and professional-looking joint.

-

Dovetail joints: Dovetail joints add strength and beauty to furniture projects, but cutting them by hand can be time-consuming and prone to error. By using a dovetail jig, woodworkers can achieve precise and uniform dovetails quickly and easily.

-

Cabinet doors: Building cabinet doors with inset panels requires precise routing and fitting. A door-making jig simplifies the process by guiding the router and ensuring accurate cuts, resulting in perfectly fitted doors every time.

-

Circle cutting: Cutting circles accurately can be a challenge without the right tools. A circle cutting jig attached to a router allows woodworkers to create perfect circles of various sizes with ease.

-

Picture frames: Creating picture frames with mitered corners requires precise angle cuts and alignment. A miter sled or jig can simplify this process by guiding the saw and ensuring accurate and tight joints.

These are just a few examples of how jigs and fixtures can simplify complex woodworking tasks. Whether you’re a beginner or an experienced woodworker, investing in quality jigs and fixtures can greatly improve the quality of your projects and save you time and frustration in the workshop.

FAQ:

Why should I use jigs and fixtures in woodworking?

Jigs and fixtures help simplify complex woodworking tasks by providing a stable and accurate guide for cutting, drilling, or shaping wood. They ensure consistency and precision, resulting in better quality workpieces.

What types of woodworking jigs and fixtures are commonly used?

There are various types of jigs and fixtures used in woodworking, including crosscut sleds, router jigs, doweling jigs, and box joint jigs. Each type is designed to assist in a specific task and make it easier and more precise.

How do jigs and fixtures improve safety in woodworking?

Jigs and fixtures can help improve safety in woodworking by providing a secure and stable setup for cutting or shaping wood. They reduce the chances of accidents or mistakes, as they hold the workpiece in place and prevent it from moving during the operation.

Can I build my own jigs and fixtures?

Absolutely! Many woodworkers prefer to build their own jigs and fixtures, as it allows for customization and ensures a perfect fit for their specific needs. There are also numerous plans and resources available online to help guide you in constructing your own jigs and fixtures.

Are there any disadvantages to using jigs and fixtures?

While jigs and fixtures greatly simplify complex woodworking tasks, they can also take time to construct or set up. Additionally, if not properly designed or used, they could potentially limit your creativity or flexibility in certain woodworking projects.

What are some examples of complex tasks that can be simplified with jigs and fixtures?

Complex tasks such as cutting intricate joinery, creating consistent dado or groove cuts, or shaping irregular curves can be made much easier and more accurate with the use of jigs and fixtures. They provide the necessary guidance and support to achieve precise and repeatable results.

Where can I purchase woodworking jigs and fixtures?

You can purchase woodworking jigs and fixtures from various sources, including woodworking supply stores, online retailers, and even directly from manufacturers. There are many options available to suit different woodworking needs and budgets.