Woodworking is a delicate art that requires precision and attention to detail. One crucial factor that can make or break a woodworker’s project is the moisture content of the wood. Moisture in wood affects its stability, strength, and overall quality. Understanding the ideal moisture content for woodworking is essential for any serious woodworker.

Wood is a natural material that absorbs and releases moisture based on the surrounding environment. When the moisture content of wood is too high or too low, it can lead to problems such as warping, shrinking, or cracking. Achieving the optimal moisture content is crucial to prevent these issues and ensure the durability and quality of the final product.

Different woodworking projects require different levels of moisture content in the wood. For furniture making, the ideal moisture content is typically around 6-8%. This range ensures that the wood is stable and won’t shrink or expand significantly after the project is completed. For outdoor projects, like decking or fencing, a slightly higher moisture content of around 10-12% may be acceptable due to the exposure to varying weather conditions.

Measuring the moisture content of wood can be done using a moisture meter, which provides an accurate reading of the wood’s moisture content. It is essential to check the moisture content of the wood before starting any woodworking project and periodically throughout the process to ensure that it remains within the desired range. Proper storage and conditioning of the wood can also help maintain the ideal moisture content for woodworking.

In conclusion, understanding the moisture content of wood and its effect on woodworking projects is vital for any woodworker. By ensuring that the wood has the appropriate moisture content, woodworkers can create durable, high-quality pieces that will stand the test of time.

What is the Ideal Moisture Content for Woodworking?

When working with wood, it is important to consider its moisture content. Wood is a hygroscopic material, meaning it naturally absorbs and releases moisture from the surrounding environment. Understanding the ideal moisture content for woodworking is crucial as it can greatly affect the quality and stability of finished wood products.

The ideal moisture content for woodworking typically ranges between 6% and 8%. This range is considered optimal for most woodworking projects. When wood has a moisture content within this range, it is more stable and less prone to warping, cracking, and other forms of distortion. However, the specific ideal moisture content can vary depending on factors such as the type of wood and the intended use of the finished product.

Wood with a moisture content below 6% is considered too dry for most woodworking projects. Dry wood can become brittle and difficult to work with. It is more likely to split and crack during the construction process, and the finished product may also be prone to further drying, leading to potential structural issues.

On the other hand, wood with a moisture content higher than 8% is considered too wet for woodworking. Wet wood is more likely to shrink, warp, and deform as it dries. This can result in joints coming loose, doors not fitting properly, and general instability of the finished product. Additionally, wet wood can also promote the growth of mold and fungi, which can be detrimental to both the wood and the health of those working with it.

To ensure that wood is within the ideal moisture content range, woodworkers use moisture meters or moisture detectors. These tools measure the moisture content of the wood by penetrating the surface and providing a reading. By regularly checking the moisture content, woodworkers can make necessary adjustments, such as allowing the wood to dry or applying moisture to achieve the desired level.

In conclusion, the ideal moisture content for woodworking typically falls between 6% and 8%. It is important to consider the moisture content of wood to ensure stable and high-quality finished products. Using moisture meters or moisture detectors can help woodworkers monitor and adjust the moisture content as needed.

The Importance of Moisture Content in Woodworking

Moisture content is a critical factor to consider in woodworking projects. Wood is a natural material that can absorb or release moisture depending on the surrounding environment. Understanding and controlling the moisture content of wood is crucial for creating durable and high-quality wood products.

Here are several reasons why monitoring and managing moisture content is important in woodworking:

- Dimensional Stability: Wood is prone to shrinkage or expansion as it gains or loses moisture. By ensuring that the wood has the appropriate moisture content, woodworkers can minimize changes in dimensions of the final product. This is particularly important for furniture, cabinetry, and other woodworking projects where precise measurements are essential.

- Strength and Durability: Wood with an excessively high or low moisture content can be weaker and more prone to damage. If the wood is too wet, it can weaken joints and make the final product structurally unsound. Conversely, if the wood is too dry, it can become brittle and susceptible to cracking or splitting. Properly dried wood with the appropriate moisture content ensures optimal strength and durability.

- Finishing and Gluing: Wood that is too wet or too dry can cause issues with finishing and gluing. Excessive moisture can lead to uneven drying times and result in surface imperfections or warped wood. On the other hand, dry wood may not hold glue properly, leading to weak adhesion. By controlling the moisture content, woodworkers can achieve better finishing results and stronger bonds.

- Preventing Mold and Decay: Wood with high moisture content is at risk of mold growth and decay. Moist conditions can provide an ideal environment for fungal growth, which can compromise the structural integrity of the wood. By ensuring that the wood has a suitable moisture content, woodworkers can reduce the risk of mold and decay, thus increasing the longevity of the finished product.

- Minimizing Warping and Movement: Changes in moisture content can cause wood to warp, twist, or cup. This can lead to misaligned joints, uneven surfaces, and overall instability of the wood product. By carefully monitoring and controlling the moisture content, woodworkers can minimize the likelihood of warping and movement, resulting in a more aesthetically pleasing and functional final product.

To effectively manage the moisture content in woodworking, woodworkers often rely on moisture meters and proper storage and drying techniques. By understanding the importance of moisture content and taking the necessary precautions, woodworkers can create high-quality, durable, and visually appealing wood products.

How Moisture Affects Woodworking Projects

Moisture is a critical factor that affects woodworking projects in various ways. Understanding the impact of moisture content on wood is essential for successful woodworking. Here are some key points to consider:

Wood Movement:

Wood is a hygroscopic material, meaning it can absorb and release moisture based on the surrounding environment. This moisture content directly affects the dimensions and stability of wood. As wood absorbs moisture, it expands, and as it loses moisture, it contracts. This natural movement can cause significant changes in the size, shape, and fit of woodworking projects.

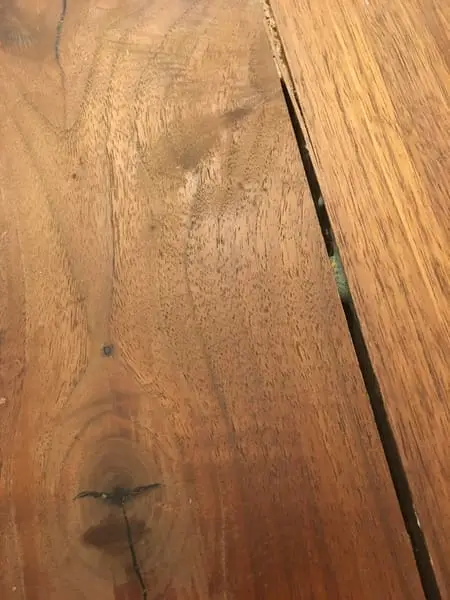

Cracking and Warping:

High moisture content in wood can lead to cracking and warping. When wood absorbs excessive moisture unevenly, the internal stresses can cause it to warp or twist. This can result in uneven surfaces, joints that don’t fit properly, and overall structural instability. On the other hand, low moisture content can cause the wood to dry out and crack.

Joinery and Assembly:

Moisture content plays a crucial role in joinery and assembly processes. Wood with high moisture content should not be used for joinery, as it can shrink and weaken the joints over time. It is essential to ensure that the moisture content of the wood is appropriate for the intended joinery techniques to achieve strong and durable connections in woodworking projects.

Finishing:

Moisture content also affects the finishing process of woodworking projects. Applying finishes, such as varnish or paint, to wood with high moisture content can lead to issues like poor adhesion, peeling, and bubbling. It is crucial to allow the wood to stabilize at the recommended moisture content range before applying any finishes to achieve a smooth and long-lasting finish.

Wood Storage:

Proper storage is vital to maintaining the moisture content of wood prior to starting a woodworking project. Wood should be stored in a controlled environment to ensure it reaches equilibrium moisture content (EMC) with its surroundings. This helps to minimize wood movement and reduce the risk of issues like warping and cracking when working with the wood.

Measuring Moisture Content:

Woodworkers rely on moisture meters to determine the moisture content of wood before beginning a project. Moisture meters provide a quick and accurate measurement of the wood’s moisture content, allowing woodworkers to make appropriate adjustments in their woodworking processes, such as drying or acclimating the wood before use.

Understanding the impact of moisture on woodworking projects is crucial for ensuring the quality and longevity of finished pieces. By considering moisture content at each stage of the woodworking process, from wood selection to storage and finishing, woodworkers can minimize issues and create beautiful, durable projects.

Common Problems Caused by Improper Moisture Content

- Warped Wood: When wood has a high moisture content, it can warp and twist as it dries. This can lead to misaligned joints and a decrease in the overall quality of the finished product.

- Cracking and Splitting: Wood that is too dry can crack and split, especially when exposed to changes in temperature and humidity. This can affect the structural integrity of the wood and make it more prone to further damage.

- Excessive Shrinkage: Wood that is not properly dried or acclimated can shrink excessively, causing gaps and misalignments. This can be especially problematic in joinery work where precise measurements are crucial.

- Poor Glue Joints: High moisture content in wood can interfere with the adhesion of glues and adhesives, leading to weak or failed joints. This can compromise the strength and durability of the finished project.

- Mold and Mildew Growth: Wood that is too moist can provide an ideal environment for mold and mildew to thrive. This not only affects the appearance of the wood, but it can also lead to health issues for those working with the wood.

- Warping of Finished Objects: Even after a piece of woodwork is completed, improper moisture content can cause it to warp or change shape over time. This can result in a finished product that does not meet the intended specifications or functions as intended.

Measuring Moisture Content in Wood

Measuring the moisture content in wood is essential for any woodworking project, as it helps determine the wood’s stability and suitability for specific applications. There are several methods available, each with its advantages and limitations:

- Moisture meters: Moisture meters are widely used by woodworkers to measure the moisture content of wood quickly and accurately. They work by using electrical resistance or capacitance to determine the moisture level. Moisture meters are available in two types: pin-type and pinless. Pin-type meters measure moisture by inserting two pins into the wood, while pinless meters use electromagnetic signals to measure moisture without damaging the wood surface.

- Oven-drying method: The oven-drying method involves weighing a wood sample, drying it in an oven set at a specific temperature, and then re-weighing it until the weight remains constant. The difference in weight before and after drying represents the moisture content of the wood. This method provides an accurate measurement but can be time-consuming.

- Electrical resistance method: The electrical resistance method measures the moisture content of wood by passing an electric current through the material and measuring the resulting resistance. As the moisture content increases, the electrical resistance decreases. This method is convenient for large-scale measurements and is commonly used in the lumber industry.

- Gravimetric method: The gravimetric method involves weighing a wood sample, drying it in a desiccator until it reaches constant weight, and then calculating the moisture content based on the weight loss. This method provides accurate results but requires a precise balance for measurements.

Regardless of the method used, it is important to measure the moisture content at multiple points in the wood to account for any variations. Wood with a moisture content of around 6-8% is usually considered suitable for indoor woodworking projects. Higher moisture levels may result in warping, cracking, or other issues, while lower moisture levels may lead to excessive shrinkage.

Woodworkers should also consider the specific requirements of their projects when determining the ideal moisture content. For example, wood used for furniture making may require a lower moisture content compared to wood used for construction purposes.

By accurately measuring the moisture content in wood, woodworkers can ensure the quality and durability of their projects, avoiding potential problems caused by improper moisture levels.

Drying Wood for Woodworking

Properly drying wood is an essential step in the woodworking process. When wood contains too much moisture, it can lead to various issues, such as warping, cracking, and even mold growth. To ensure the best results in your woodworking projects, it is crucial to dry the wood to the appropriate moisture content. Here’s a comprehensive guide on how to dry wood for woodworking:

1. Harvesting the Wood

Wood should be harvested at the right time to obtain the best quality. It is recommended to fell trees during the dormant season, when the tree is less likely to contain excessive moisture. This helps prevent the wood from drying too slowly or retaining too much moisture.

2. Initial Air Drying

After harvesting, the wood should undergo an initial air drying process. This involves stacking the wood with spacers in between to allow for proper air circulation. The wood should be protected from direct sunlight and rain but still exposed to air. This helps remove excess moisture and reduces the chances of warping or cracking.

3. Monitoring Moisture Content

Regularly monitor the moisture content of the wood using a moisture meter. The ideal moisture content for woodworking purposes is typically around 6-8%. This measurement ensures that the wood is stable and less prone to future issues. Be patient and allow the wood to dry gradually, as rushing the process may lead to problems.

4. Air Drying Duration

The duration of the air drying process depends on various factors, such as the wood species, thickness, and environmental conditions. Generally, it can take several months to a year for wood to air dry to the desired moisture content. Thicker boards may require more time. It is important to be patient and avoid rushing the process.

5. Kiln Drying

For more precise control over the drying process, woodworkers often opt for kiln drying. Kiln drying involves placing the wood in a controlled environment with carefully regulated temperature and humidity levels. This process can significantly speed up the drying time and ensure a more predictable moisture content.

6. Storing Dried Wood

Once the wood has reached the desired moisture content, it should be stored in a dry and well-ventilated space. Stack the wood with spacers to maintain proper airflow and prevent moisture buildup. Keep the wood protected from moisture, extreme temperature changes, and direct sunlight to maintain its quality.

In conclusion, drying wood for woodworking is a critical step to prevent future issues and ensure optimal results. Proper harvesting, initial air drying, moisture monitoring, air drying duration, kiln drying, and proper storage are all essential aspects of the wood drying process. By following these guidelines, you can enhance the quality and stability of the wood, leading to successful woodworking projects.

Methods of Drying Wood

There are several methods of drying wood, each with its advantages and disadvantages. The choice of drying method depends on the type of wood, its thickness, and the intended use of the wood. Here are some common methods of drying wood:

- Air Drying: This is the most basic method of drying wood and involves leaving the wood exposed to the air to naturally dry over time. Air drying is a slow process that takes several months or even years, depending on the thickness and type of wood. While this method is inexpensive, it can result in uneven drying and may not be suitable for certain types of wood.

- Kiln Drying: Kiln drying is a controlled method of drying wood that uses heat and humidity to speed up the drying process. The wood is loaded into a kiln where temperature, humidity, and airflow are carefully monitored and controlled. Kiln drying can take several days to weeks, depending on the thickness of the wood. This method provides more uniform drying and reduces the risk of wood warping, but it can be more expensive than air drying.

- Steam Drying: Steam drying is a variation of kiln drying that involves steaming the wood before drying it. Steaming helps to remove internal stresses and can improve the stability of the wood. This method is often used for thick, heavy timbers or for wood that has a high risk of checking or cracking.

- Vacuum Drying: Vacuum drying is a method that uses reduced pressure to lower the boiling point of water, allowing the wood to dry at lower temperatures. This method helps to preserve the natural color and appearance of the wood, but it requires specialized equipment and can be expensive.

Regardless of the drying method used, it is important to monitor the moisture content of the wood to ensure it reaches the desired level for woodworking. Properly dried wood is essential for preventing warping, checking, and other issues that can affect the quality and durability of the final product.

Preventing Moisture Changes in Wood

Wood is a natural material that is sensitive to changes in moisture levels. These changes can cause the wood to warp, swell, or shrink, leading to structural problems and aesthetic issues.

Fortunately, there are several precautions you can take to prevent moisture changes in wood:

- Choose the Right Wood: Some types of wood are more resistant to moisture changes than others. Hardwoods like oak, cherry, and mahogany are less likely to warp or shrink compared to softwoods like pine or cedar. Consider using more stable woods for your woodworking projects.

- Season and Dry the Wood Properly: Green or freshly cut wood contains a high moisture content that needs to be reduced. This process is called seasoning or drying the wood. Proper seasoning typically involves air-drying the wood, allowing the moisture content to decrease slowly over time. Kiln-drying is another option, but it can be more expensive.

- Store Wood in a Controlled Environment: Once the wood is properly seasoned, it should be stored in a controlled environment. This means keeping the wood in a location with stable temperature and humidity levels. Avoid storing wood in damp or humid areas like basements or garages.

- Protect Wood from Direct Contact with Moisture: In woodworking projects, it’s essential to protect the wood from direct contact with moisture. This can be achieved by using finishes such as varnish, lacquer, or oil, which provide a protective layer. Additionally, using sealants or edge banding can prevent moisture from seeping into the wood.

- Minimize Exposure to Water: Wood should be kept away from sources of water, including leaks, spills, or high humidity areas. Avoid placing wooden furniture or projects near sinks, bathroom fixtures, or appliances that produce moisture.

- Maintain a Stable Environment: Fluctuations in temperature and humidity levels can cause wood to expand or contract. To prevent moisture changes, maintain a stable environment by using humidifiers or dehumidifiers as needed. It’s especially important to control humidity levels during seasonal changes.

By following these precautions, you can help prevent moisture changes in wood and ensure the longevity and quality of your woodworking projects.

Final Thoughts on Moisture Content in Woodworking

Moisture content is a crucial factor to consider in woodworking projects. It affects the stability, strength, and overall quality of the finished piece. Before starting any woodworking project, it is important to understand the moisture content of the wood you are working with.

Why is moisture content important?

Wood is a hygroscopic material, which means it can absorb and release moisture depending on the surrounding environmental conditions. This natural process can cause wood to expand or contract, leading to warping, splitting, and other structural issues. By understanding and controlling the moisture content, woodworkers can ensure that their projects remain stable and durable over time.

There are different moisture content standards for different woodworking applications. For example, green wood, which has a moisture content above 30%, is often used for woodturning and carving because it is easier to work with. On the other hand, kiln-dried wood with a moisture content of less than 12% is preferred for furniture making because it is less likely to warp or crack.

How to measure moisture content?

Wood moisture meters are commonly used to measure the moisture content of wood. These handheld devices use electrical resistance or capacitance to determine the moisture levels within the wood. By measuring the moisture content at different points of a wood piece, woodworkers can determine if it is at the desired moisture level for their specific project.

Controlling moisture content

To ensure the desired moisture content, woodworkers can use various methods to control and stabilize the wood. This includes air drying, kiln drying, or using a moisture barrier such as paint or a finish. It is important to note that wood can continue to gain or lose moisture after the woodworking process, so proper storage and acclimation are also essential.

In conclusion

Moisture content plays a significant role in woodworking. Understanding and controlling the moisture content of wood is essential to ensure the quality and longevity of the finished project. By using appropriate measurement tools and employing proper drying and storage techniques, woodworkers can create beautiful and durable pieces that will withstand the test of time.

FAQ:

What are the different moisture content levels for different types of wood?

The moisture content levels for different types of wood vary, but generally, hardwood should be around 6-8% moisture content, while softwood should be around 9-14% moisture content.

Why is it important to have the right moisture content in wood for woodworking?

The right moisture content is important in wood for woodworking because if the wood is too wet, it can warp, shrink, or crack after it is worked on. If the wood is too dry, it may become brittle and difficult to work with.

How can I check the moisture content of wood?

There are several methods to check the moisture content of wood. The most common method is by using a moisture meter, which measures the electrical resistance of the wood to determine its moisture content. Another method is by weighing the wood before and after drying it in an oven to calculate its moisture content.

What are the potential problems that can occur if wood with the wrong moisture content is used in woodworking?

If wood with the wrong moisture content is used in woodworking, it can lead to various problems. For example, if the wood is too wet, it can cause joint failure, warping, and splitting. If the wood is too dry, it may result in brittle and weak joints, as well as difficulty in shaping or carving the wood.