When it comes to art and craftsmanship, few things can match the beauty and intricacy of celadon pottery. With its unique jade-like glaze and delicate designs, celadon pottery has been admired and treasured for centuries. In this article, we will take a deep dive into the history and artistry behind this ancient form of pottery.

Originating in China during the Song Dynasty (960-1279), celadon pottery quickly spread throughout East Asia and became highly sought after by collectors and connoisseurs. The name “celadon” is derived from the French word “celadon,” which refers to a pale and delicate shade of green, reminiscent of the glaze used on these ceramics.

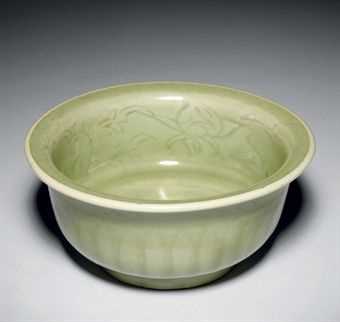

What sets celadon pottery apart from other types of pottery is its distinctive glaze. The glaze is made by firing the pottery in a reduction kiln with a controlled amount of oxygen, creating a chemical reaction that produces the characteristic green color. The glaze also gives the pottery a smooth and lustrous finish, making it highly desirable.

The artistry of celadon pottery lies in the intricate designs and patterns that are often hand-carved or painted onto the surface. These designs can range from simple geometric shapes to intricate floral motifs, intertwining dragons, and mythical creatures. The skill and precision required to create these designs are a testament to the talent and craftsmanship of the artisans.

“Celadon pottery is not just an art form, but also a window into the rich cultural heritage and history of East Asia.”

Throughout history, celadon pottery has had a significant influence on the development of ceramic arts in East Asia. It has inspired and influenced various regional styles, such as the Korean buncheong ware and the Japanese Seto celadon, each with its own unique characteristics and techniques.

Today, celadon pottery continues to be admired and collected by art enthusiasts around the world. Whether displayed as a work of art or used in everyday life, celadon pottery is a testament to the timeless beauty and craftsmanship that transcends generations.

What is Celadon Pottery?

Celadon pottery is a type of ceramic that originated in China during the Song Dynasty and is known for its distinctive pale green color. The term “celadon” is named after a pale green variety of jade called “qīngcé” in Chinese, which is often used to describe the color of this pottery.

To create celadon pottery, a specific type of glaze is applied to the ceramic surface before firing. This glaze contains a small amount of iron oxide, which interacts with the heat of the kiln to create the characteristic green color. The glaze is often applied with a technique called “inlay” or “carving” where different layers of glaze are carefully brushed, carved, or incised to create intricate designs and patterns.

Celadon pottery is typically made from a mixture of porcelain and clay, which gives it a smooth and translucent appearance. The pottery is then fired at a high temperature, resulting in a durable and waterproof finish.

Historically, celadon pottery was highly regarded and sought after in ancient China, Korea, and other parts of East Asia. It was often reserved for the imperial court and high-ranking officials due to its association with luxury and elegance. Today, celadon pottery is still highly regarded as a traditional art form and is appreciated for its beauty and craftsmanship.

Examples of celadon pottery can be found in museums and collections around the world. The delicate green color and intricate designs continue to captivate art enthusiasts and collectors, making celadon pottery a timeless and cherished art form.

The History of Celadon Pottery

Celadon pottery is a type of ceramic that has a long and rich history. It originated in China during the Song Dynasty, which lasted from the 10th to the 13th century. The term “celadon” refers to the pale green color of the glaze that is used to coat the pottery.

The production of celadon pottery requires skill and precision. The clay used for celadon pottery is usually made from a mixture of different types of clay, including white clay, kaolin, and quartz. This special clay mixture gives celadon pottery its unique properties and appearance.

During the Song Dynasty, celadon pottery became very popular and was highly prized. It was often used by the upper class as a symbol of wealth and status. The production of celadon pottery was highly regulated by the government, and only skilled artisans were allowed to create it.

Celadon pottery is known for its delicate and elegant designs. Many celadon pieces are decorated with intricate carvings and patterns, which are often inspired by nature. The glaze used on celadon pottery gives it a smooth and glossy finish, and the pale green color is achieved through the use of iron oxide.

Celadon pottery reached its peak of popularity during the Goryeo Dynasty in Korea, which lasted from the 10th to the 14th century. The celadon produced during this time is characterized by its stunning celadon blue-green color and exquisite craftsmanship.

Today, celadon pottery continues to be produced and enjoyed around the world. It is highly regarded for its beauty and craftsmanship, and many collectors and art enthusiasts seek out celadon pieces. Whether it’s a functional vase or a decorative plate, celadon pottery is a true work of art that reflects the rich history and cultural heritage of the East.

The Making of Celadon Pottery

Celadon pottery is a traditional form of ceramic art that originated in ancient China. The making of celadon pottery involves several intricate steps that require skill and attention to detail. Here is a step-by-step guide to the process:

- Selection of Clay: The first step in making celadon pottery is selecting the right type of clay. Clay with a high iron content is preferred as it helps create the characteristic green color of celadon.

- Kneading: The clay is then kneaded to remove any air bubbles and to ensure a smooth texture. This process involves pressing and folding the clay repeatedly.

- Shaping: The next step is shaping the clay into the desired form. This can be done using different techniques such as wheel throwing, hand building, or mold casting.

- Drying: Once shaped, the pottery is left to dry slowly. This allows the clay to harden and prevents cracking during the firing process.

- Carving and Decoration: After drying, the pottery is carved or decorated with intricate patterns. This can be done using a variety of tools and techniques, such as incising or adding clay appliques.

- Firing: The final step in making celadon pottery is firing it in a kiln. The pottery is placed in the kiln and fired at a high temperature, usually around 1200-1300 degrees Celsius. This process transforms the clay into a durable ceramic material.

- Glazing: Once the pottery has been fired, it is coated with a special glaze made from a mixture of feldspar, quartz, and other minerals. The glaze gives celadon pottery its characteristic green color.

- Second Firing: After glazing, the pottery is fired for a second time. This firing helps to seal the glaze and enhance its color and texture.

- Finishing: The final step involves inspecting the finished pottery for any imperfections and adding any final touches, such as polishing the surface or adding a protective coating.

The making of celadon pottery is a labor-intensive process that requires patience, skill, and creativity. Each piece is unique and reflects the craftsmanship and artistry of the potter.

Materials Used in Celadon Pottery

Celadon pottery is known for its unique green glaze, which is achieved through a combination of specific materials. The key materials used in celadon pottery include:

- Clay: Celadon pottery is typically made from a type of clay that has a high content of iron oxide. This clay is known for its plasticity and ability to hold shape during firing.

- Iron Oxide: Iron oxide is added to the clay to give it a rich green color. The amount of iron oxide used can vary and affects the final hue of the celadon glaze.

- Feldspar: Feldspar is a type of mineral that is used as a flux in the glaze. It helps the glaze to melt and adhere to the surface of the pottery during firing.

- Quartz: Quartz is added to the clay to improve its strength and durability. It also helps to prevent the pottery from cracking or warping during firing.

- Wood Ash: Wood ash is sometimes used in celadon pottery to achieve a unique texture and color variation in the glaze. The wood ash reacts with the other materials during firing and can create interesting effects.

In addition to these main materials, various other natural minerals and pigments can be added to the glaze to create different colors and effects. Each potter has their own unique recipe for the glaze, which they often guard as a trade secret.

The combination of these materials and the precise techniques used in celadon pottery result in the beautiful and distinctive green glaze that is characteristic of this art form.

The Process of Creating Celadon Pottery

Creating celadon pottery is a meticulous and complex process that requires the skill and expertise of master artisans. The following steps outline the traditional method of making this exquisite type of pottery.

-

Clay Preparation: The process begins with selecting the clay for the pottery. The clay must have specific characteristics to achieve the desired celadon color and texture. It is then mixed with water and left to ferment for a certain period of time to enhance its plasticity.

-

Throwing: Once the clay is ready, the potter will begin throwing the pottery on a potter’s wheel. They use their hands and tools to shape the clay into the desired form, such as bowls, vases, or cups. This requires precision and careful attention to detail.

-

Drying: After shaping the pottery, it is left to dry partially before the next step. This allows the potter to carve intricate designs into the surface, adding to the beauty of the final product.

-

Carving: The partially dried clay is then carefully carved with intricate designs. These designs can be floral patterns, mythical creatures, or other symbolic motifs. The potter uses special carving tools to create the desired patterns, ensuring utmost precision and finesse.

-

Bisque Firing: Once the carving is complete, the pottery is fired in a kiln at a relatively low temperature. This process, known as bisque firing, helps to remove any remaining moisture from the clay and makes it more durable for the next step.

-

Glazing: The bisque-fired pottery is then dipped into a specially prepared celadon glaze. This glaze contains traces of iron oxide, which gives celadon its unique translucent green color when fired. The glaze is carefully applied to ensure an even and smooth coating.

-

Final Firing: After glazing, the pottery is fired again in a kiln at a higher temperature. This final firing is what transforms the pottery into celadon, as the iron oxide in the glaze reacts with the heat to create the characteristic green color. The duration and temperature of this firing process can vary, depending on the desired effect and the specific type of celadon being produced.

-

Finishing: Once the final firing is complete, the celadon pottery is carefully inspected for any imperfections. If necessary, the pottery may undergo additional polishing or glazing to achieve the desired finish. The finished pieces are now ready to be admired and used for various purposes, such as decorative items or functional tableware.

The process of creating celadon pottery requires not only technical skills but also an artistic vision. Each piece is a testament to the craftsmanship and dedication of the artisans who preserve this ancient art form. Celadon pottery continues to be highly valued and sought after around the world for its beauty and historical significance.

The Significance of Celadon Pottery

Celadon pottery holds immense significance in the history of ceramics and art. Its origins can be traced back to ancient China, where it was highly prized and considered a symbol of wealth and status.

One of the most remarkable aspects of celadon pottery is its distinctive green color. This color is achieved through a unique and intricate glazing process, which involves a combination of iron oxide and ash glazes fired at high temperatures in a reduction atmosphere kiln. The resulting color ranges from pale green to a deep jade tone, often resembling the color of jadeite.

Beyond its exquisite appearance, celadon pottery is also known for its exceptional craftsmanship and technical skill. The creation of celadon pieces requires precision and a deep understanding of the ceramic medium. The potters must carefully control factors such as temperature, glaze composition, and firing techniques to achieve the desired result.

Celadon pottery holds deep cultural and historical significance in many Asian countries. In China, celadon has been highly valued since the Song Dynasty (960-1279) and was often used by the imperial court. It was also exported to other regions, such as Southeast Asia and the Middle East, where it became highly sought after.

In Korea, celadon pottery, known as “Goryeo celadon,” reached its peak during the Goryeo Dynasty (918-1392). The delicate shape, exquisite craftsmanship, and beautiful green color of Goryeo celadon made it highly regarded and cherished. It is considered one of Korea’s national treasures.

The beauty and cultural significance of celadon pottery continue to be appreciated and celebrated to this day. Its timeless elegance and unique green color make it a highly sought-after artistic medium and a valuable collector’s item.

Cultural and Artistic Importance

The celadon pottery holds significant cultural and artistic importance in various aspects. The art of celadon pottery originated in ancient China during the Eastern Zhou Dynasty (771-256 BC) and was later introduced to Korea during the Goryeo Dynasty (918-1392 AD).

Cultural Significance:

- Celadon pottery is often seen as a symbol of high social status and sophistication.

- It reflects the cultural exchange and influence between China and Korea.

- The production of celadon pottery requires a high level of craftsmanship and technical skill, representing the cultural heritage and tradition of the artisans.

- Throughout history, celadon pottery has been used for various purposes, including as tableware for royal and noble families.

- It has been an important part of religious rituals and ceremonies.

Artistic Significance:

- Celadon pottery is renowned for its exquisite beauty and delicate craftsmanship.

- The unique green glaze of celadon is achieved through a specific firing technique, resulting in a beautiful color reminiscent of jade.

- The intricate designs and patterns carved onto celadon pottery showcase the artistic skills and creativity of the craftsmen.

- The use of celadon pottery as a canvas for decorative motifs and storytelling reflects the artistic expression of the era in which it was made.

In addition to its cultural and artistic importance, celadon pottery also played a significant role in trade between China, Korea, and other countries. It served as a desirable luxury item and was exported to various regions, contributing to the economic development of the time.

Overall, celadon pottery has left a lasting impact on both the cultural history and artistic heritage of China and Korea. Its beauty and craftsmanship continue to be appreciated and admired by art enthusiasts and collectors around the world.

The Influence of Celadon Pottery on Other Art Forms

Throughout history, celadon pottery has had a significant impact on various art forms. Its unique beauty and delicate craftsmanship have inspired artists, designers, and craftsmen across different cultures. Here are some art forms that have been influenced by celadon pottery:

- Ceramics: Celadon pottery has been a major source of inspiration for ceramic artists worldwide. Its distinctive green color, smooth glaze, and elegant forms have influenced the creation of new ceramic techniques and styles.

- Porcelain: The development of celadon pottery played a crucial role in the history of porcelain-making. The success of celadon glazes led to advancements in ceramic technology, including the creation of translucent porcelain.

- Calligraphy: Celadon pottery, with its graceful shapes and poetic designs, has influenced calligraphers in their artistic expressions. The combination of the fluid lines found in calligraphy and the intricate patterns of celadon have often been compared and celebrated together.

- Literature: Celadon pottery has been a subject of inspiration in literature, particularly in East Asian poetry and prose. Writers and poets have often used celadon as a symbol of beauty, refinement, and the passage of time.

- Painting: The colors and textures of celadon pottery have influenced painters’ techniques in capturing light, form, and texture on canvas. Artists have experimented with emulating the subtle shades of celadon in their artworks.

- Architecture: The aesthetic principles of celadon pottery have influenced architectural design, particularly in East Asian traditional buildings. The emphasis on simplicity, harmony, and balance in celadon has been translated into architectural elements.

Celadon pottery’s influence on various art forms highlights its enduring significance and timeless appeal. Its artistry continues to inspire and captivate artists and art enthusiasts around the world.

FAQ:

What is celadon pottery?

Celadon pottery is a type of ceramic ware that is known for its greenish-blue glaze and delicate craftsmanship. It originated in ancient China during the Song Dynasty and has since been produced in various Asian countries.

What are the characteristics of celadon pottery?

Celadon pottery is characterized by its distinct celadon glaze, which gives it a green or blue color. It is often adorned with intricate carvings and designs, and is known for its thin and delicate walls.

How is celadon pottery made?

Celadon pottery is made using a specific type of clay and glaze. The clay is shaped into the desired form, such as a vase or a bowl, and fired in a kiln. After the first firing, the pottery is coated with the celadon glaze and fired again at a higher temperature.

What is the history of celadon pottery?

Celadon pottery has a rich history that dates back over a thousand years. It was first created in China during the Song Dynasty, and soon became highly prized and sought after. Celadon pottery was considered a symbol of wealth and sophistication, and was used by the ruling class and the nobility.

Where can I see examples of celadon pottery?

There are many museums and art galleries around the world that have collections of celadon pottery. Some famous examples include the National Palace Museum in Taiwan, the Asian Art Museum in San Francisco, and the British Museum in London. You can also find celadon pottery for sale in specialty stores and online.