Marshall Pottery, founded in 1895 in Marshall, Texas, has a rich history and a reputation for producing high-quality pottery. However, in recent years, the company has faced numerous challenges that have led to its decline. In this article, we will conduct a comprehensive investigation into what exactly happened to Marshall Pottery and explore the factors that contributed to its downfall.

One of the key factors in the decline of Marshall Pottery was the rise of mass-produced, cheaper pottery from overseas. As consumers increasingly sought out more affordable options, Marshall Pottery struggled to compete with the lower prices offered by imports. This led to a significant decline in sales and revenue for the company.

Another significant issue for Marshall Pottery was the changing consumer preferences and trends. With the shift towards more modern and minimalist home decor, the demand for traditional pottery styles, which Marshall Pottery specialized in, started to decline. The company struggled to adapt and keep up with the changing tastes of consumers, further contributing to its decline.

Despite the challenges it faced, Marshall Pottery remained a beloved and iconic brand in Marshall, Texas, and the surrounding area. The company had a strong community presence and a loyal customer base who appreciated the craftsmanship and authenticity of their products. However, even this support wasn’t enough to save the company from its ultimate fate.

In addition to these external factors, there were also internal issues that plagued Marshall Pottery. Financial mismanagement and a lack of innovation were some of the key problems that hindered the company’s growth and profitability. These issues, combined with the external challenges the company faced, created a perfect storm that ultimately led to the downfall of Marshall Pottery.

Through this comprehensive investigation, we hope to shed light on the factors that contributed to the decline of Marshall Pottery. By understanding the challenges faced by the company, we can gain valuable insights into the broader trends and issues affecting the pottery industry as a whole. Join us as we delve into the story of Marshall Pottery and uncover the lessons that can be learned from its fall.

The Rise of Marshall Pottery

Marshall Pottery, located in Marshall, Texas, has a rich history that dates back over 125 years. The pottery was founded in 1895 by W. F. Rocker and has since become one of the leading manufacturers of stoneware in the United States.

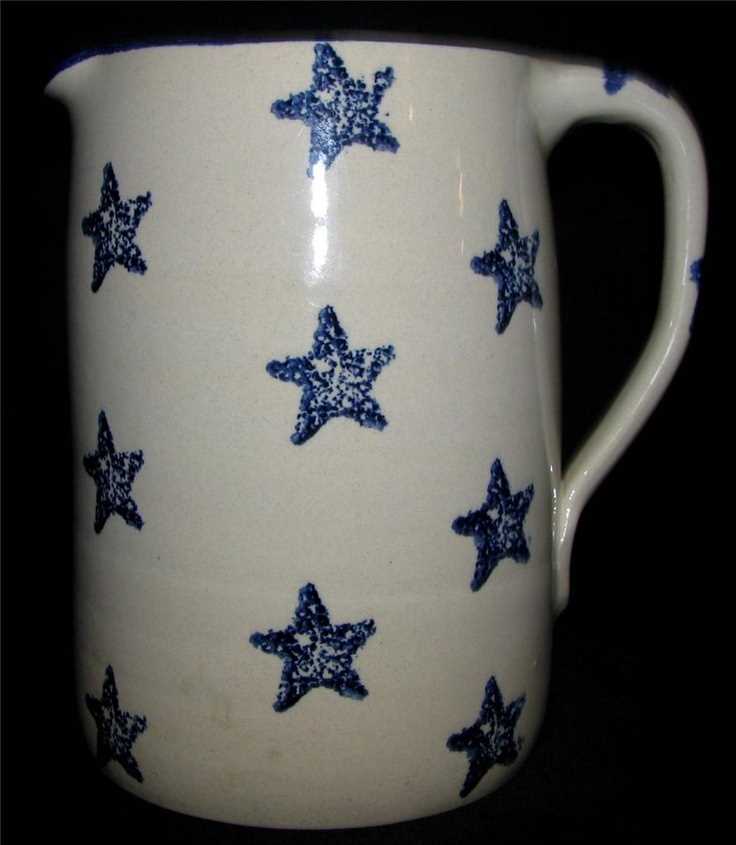

The early years of Marshall Pottery were focused on producing utilitarian stoneware items, such as crocks, churns, and jugs, that were essential for everyday life in the late 19th and early 20th centuries. The pottery quickly gained a reputation for producing high-quality, durable products that were known for their distinctive and unique designs.

As the demand for stoneware declined in the mid-20th century, Marshall Pottery adapted to the changing times and began producing more decorative and artistic pottery pieces. The pottery expanded its product line to include flower pots, vases, and other decorative items, which resonated with a new generation of consumers.

Marshall Pottery’s commitment to craftsmanship and quality has been a driving force behind its success. The pottery is known for its attention to detail, using traditional techniques and skilled artisans to create each piece. The combination of traditional craftsmanship and innovative designs has made Marshall Pottery a popular choice among collectors and home decor enthusiasts.

In addition to its focus on quality, Marshall Pottery has also prioritized sustainability and environmental responsibility. The pottery employs eco-friendly practices, such as using recycled materials and reducing waste in its production processes.

Today, Marshall Pottery continues to thrive as a family-owned and operated business. The pottery is beloved by locals and has gained national recognition for its unique blend of tradition and innovation. With its long-standing history and commitment to excellence, Marshall Pottery remains an iconic institution in the world of stoneware.

Challenges and Decline in Production

The Marshall Pottery company faced several challenges and experienced a decline in production over the years. These challenges included:

- Competition from Foreign Manufacturers: As global trade expanded, Marshall Pottery faced stiff competition from foreign manufacturers who were able to produce similar products at lower costs. This resulted in a decrease in demand for Marshall Pottery’s products and a decline in sales.

- Changing Consumer Preferences: Over time, consumer preferences shifted towards more modern and mass-produced pottery options. Marshall Pottery, with its traditional handmade stoneware, struggled to capture the attention of the younger generation who preferred contemporary designs and materials.

- High Production Costs: Handcrafting pottery requires skilled artisans and labor-intensive processes, leading to higher production costs compared to automated manufacturing. This increased overhead made it challenging for Marshall Pottery to compete with mass-produced, inexpensive products flooding the market.

- Technological Advancements: The emergence of advanced machinery and equipment in the pottery industry made it easier for manufacturers to produce larger quantities in less time. Marshall Pottery’s reliance on traditional production methods became a limiting factor in terms of efficiency and scalability.

- Supply Chain Issues: In recent years, Marshall Pottery faced challenges with its supply chain, including difficulties sourcing high-quality materials and finding reliable suppliers. These issues affected production timelines, quality control, and ultimately customer satisfaction.

As a result of these challenges, Marshall Pottery saw a decline in production and struggled to stay competitive in the evolving market. However, the company continues to adapt and explore options to overcome these obstacles and revive its business.

Change in Ownership and Financial Troubles

In 2014, Marshall Pottery underwent a significant change in ownership when it was acquired by Wood Creek Capital Management. As part of this acquisition, the company’s long-time CEO, Kenneth Malinak, stepped down and was replaced by a new management team.

Unfortunately, the change in ownership did not bring the expected financial stability to the company. Marshall Pottery continued to face numerous financial troubles, including declining sales and increased competition from foreign imports. The company struggled to adapt to the changing market dynamics and found it difficult to compete with lower-cost products produced overseas.

One of the major challenges faced by Marshall Pottery was its high production costs. The company relied heavily on manual labor and traditional manufacturing processes, which were less efficient compared to modern production methods. This resulted in higher operating expenses and reduced profitability.

In addition to these operational challenges, Marshall Pottery also faced difficulties in managing its debt. The company had taken on significant loans to finance its operations and make capital investments. However, the declining sales and financial strain made it difficult for the company to meet its debt obligations.

The financial situation of Marshall Pottery worsened over time, and in 2017, the company filed for bankruptcy protection. Despite efforts to restructure and revitalize the business, Marshall Pottery was unable to overcome its financial difficulties and was ultimately forced to close its doors in 2019.

The closure of Marshall Pottery was a significant loss to the community, as the company had been a long-standing and prominent employer in the area. It also served as a symbol of the challenges faced by many traditional manufacturing businesses in the face of global competition and changing consumer preferences.

Fire Incident and Losses

On July 26, 2017, Marshall Pottery experienced a devastating fire incident that caused significant damage to their facilities and resulted in substantial losses.

The fire broke out in the early morning hours and quickly spread to multiple buildings within the pottery complex. Firefighters from several neighboring towns were called in to assist in extinguishing the flames, but the fire engulfed most of the structures before it could be fully contained.

The losses incurred during the fire were extensive. Several production buildings, including the main kiln and molding areas, were completely destroyed, along with a large inventory of finished pottery items. The warehouse, where the company stored raw materials and packaging supplies, also suffered significant damage. Machinery and equipment used for manufacturing and glazing were rendered inoperable.

In addition to the physical losses, the fire resulted in a temporary halt to production and caused major disruptions to the company’s supply chain. The loss of finished goods and raw materials affected the ability to fulfill customer orders, leading to customer dissatisfaction and potential financial losses.

The cause of the fire was determined to be a malfunctioning electrical system in one of the buildings. The exact origin of the fire could not be pinpointed due to the extensive damage caused by the flames. However, investigations revealed that outdated wiring and inadequate fire safety measures were contributing factors to the rapid spread of the fire.

Despite the significant losses suffered, Marshall Pottery demonstrated resilience and determination in rebuilding their facilities. With the support of their employees, customers, and the local community, the company was able to resume operations within a few months and gradually recover from the setbacks caused by the fire incident.

| Facilities | Inventory | Equipment |

|---|---|---|

| Production buildings | Finished pottery items | Machinery and manufacturing equipment |

| Warehouse | Glazing equipment | |

Investigation and Determining the Cause

The investigation into what happened to Marshall Pottery involved a comprehensive analysis of various factors and events leading up to the incident. A team of experts from different fields was assembled to gather and analyze the available information. The primary goal was to determine the cause of the incident and identify any contributing factors.

Multiple investigative methods were utilized, including:

- Gathering testimonies from employees and witnesses

- Reviewing surveillance footage and photographs

- Examining the pottery kilns and manufacturing equipment

- Studying the production processes and procedures

- Reviewing maintenance records and inspection reports

The investigative team also conducted interviews with relevant personnel such as supervisors, engineers, and maintenance staff. They examined the company’s safety protocols and whether they were properly implemented and followed.

Based on the evidence collected, it was determined that a combination of factors contributed to the incident. These factors include:

- Inadequate training and supervision

- Lack of proper safety precautions

- Equipment malfunction

- Potential structural issues in the production area

Further analysis revealed that a critical failure in the kiln’s temperature control system had occurred, leading to an extremely high temperature that caused the explosion. The investigation also uncovered potential deficiencies in the maintenance of the kiln and inadequate training provided to the employees operating the equipment.

Once these factors were identified, recommendations were made to improve safety protocols, training procedures, and equipment maintenance. These recommendations included implementing a more rigorous training program for employees, enhancing safety protocols, and conducting regular inspections and maintenance checks on critical equipment.

The investigation and determination of the cause not only provided valuable insights into what happened at Marshall Pottery but also led to important changes aimed at preventing similar incidents in the future and ensuring the safety of the employees.

Economic Impact on Marshall and the Surrounding Area

The closure of Marshall Pottery has had a significant economic impact on the city of Marshall and the surrounding area. With the loss of a major employer, many residents have found themselves without employment or with reduced income.

The closure of the pottery plant has also affected local businesses that relied on the pottery’s employees for customers. Restaurants, shops, and other small businesses in Marshall have seen a decline in customers and revenue since the closure.

The closure of Marshall Pottery has also had a ripple effect on the local economy. The plant’s closure has resulted in a decrease in tax revenue for the city, leading to budget cuts in public services such as schools, parks, and infrastructure improvements.

Furthermore, the closure of the pottery has caused a decline in property values in the area. Many residents who lived near the pottery plant have seen their home values decrease, making it difficult for them to sell their homes or refinance their mortgages.

Efforts are being made by the city and local organizations to mitigate the economic impact of Marshall Pottery’s closure. Some initiatives include attracting new businesses to the area, providing resources and training for displaced workers to find new employment opportunities, and promoting tourism to stimulate the local economy.

Overall, the closure of Marshall Pottery has had a profound economic impact on the city of Marshall and the surrounding area. It has affected not only the former employees of the pottery but also local businesses, tax revenue, property values, and the overall economic well-being of the community. Recovery and revitalization efforts are essential to restore economic stability to the area.

Rebuilding and Revival

After the devastating fire that destroyed Marshall Pottery in 2017, the owners and employees faced the difficult task of rebuilding and reviving the iconic pottery company. Despite the devastation and loss, the Marshall Pottery community rallied together to overcome the challenges and restore the business to its former glory.

The first step in the rebuilding process involved clearing the debris and assessing the damage. The fire had destroyed the pottery kilns, buildings, equipment, and inventory. However, the determination to resurrect Marshall Pottery was unwavering.

With a clear vision in mind, the owners decided to rebuild the pottery on the same location where it had stood for decades. This decision allowed them to honor the long history of the company and maintain a sense of continuity. Construction crews were brought in to rebuild the facilities and restore the infrastructure.

The revival of Marshall Pottery involved not only physical reconstruction but also a rejuvenation of the company’s product line. The owners took the opportunity to introduce new designs and experiment with innovative techniques. They collaborated with local artists and craftsmen to bring fresh ideas and creativity to their pottery creations.

In addition to focusing on product innovation, Marshall Pottery made efforts to improve their marketing strategies. They revamped their online presence, created a user-friendly website, and engaged with their customers through social media platforms. By revitalizing their digital marketing efforts, the company aimed to reach a wider audience and attract new customers.

The rebuilding and revival of Marshall Pottery was a challenging journey, but it also showcased the resilience and determination of the owners and employees. Through their hard work and perseverance, they were able to bring the pottery company back from the brink of destruction, securing its place as a beloved institution in Marshall, Texas.

Future Prospects and Partnerships

As Marshall Pottery looks to the future, there are several prospects and potential partnerships that could greatly benefit the company.

1. Expansion into International Markets: With its rich history and reputation for producing high-quality pottery, Marshall Pottery has the potential to expand its reach beyond the United States. By exploring opportunities in international markets, the company can tap into new customer bases and increase its global presence.

2. Collaborations with Home Décor Companies: Marshall Pottery’s handmade pottery pieces are highly sought after by home décor enthusiasts. Partnering with well-established home décor companies can provide a platform for broader distribution and exposure to a wider audience. This collaboration can also open up opportunities for designing and creating exclusive product lines.

3. Green Initiatives and Sustainable Practices: As sustainability becomes an increasingly important aspect of business operations, Marshall Pottery can explore partnerships with organizations focused on green initiatives and sustainable practices. This can include initiatives such as recycling clay waste, reducing energy consumption, and using environmentally friendly packaging materials.

4. Online Presence and E-commerce: In the digital age, having a strong online presence is crucial for the success of any business. Marshall Pottery can explore partnerships with e-commerce platforms and online marketplaces to reach a wider audience and increase sales. Additionally, establishing an online store can provide customers with the convenience of ordering directly from the company.

5. Collaborations with Artists and Designers: Collaborating with artists and designers can bring fresh perspectives and innovative designs to Marshall Pottery’s product offerings. By working with renowned artists and designers, the company can create unique collections that appeal to a broader range of customers.

6. Partnerships with Hospitality and Food Service Industries: Marshall Pottery’s durable and versatile pottery pieces make them a perfect fit for the hospitality and food service industries. By partnering with hotels, restaurants, and catering companies, the company can provide customized pottery pieces for their specific needs and increase brand exposure to a wider audience.

By exploring these prospects and nurturing partnerships, Marshall Pottery can continue to grow and thrive in the ever-evolving pottery industry. With its rich history and commitment to quality, the company is well-positioned for a successful future.

FAQ:

What is Marshall Pottery?

Marshall Pottery is a famous pottery company that was established in Marshall, Texas in 1895. It is known for its high-quality stoneware products such as pots, planters, and kitchenware.

What happened to Marshall Pottery?

Marshall Pottery faced a devastating fire in July 2012 that destroyed most of its production facility. The fire caused extensive damage to the historic building and resulted in a temporary closure of the company.

How did Marshall Pottery recover from the fire?

After the fire, Marshall Pottery went through a long and challenging recovery process. The company received support from the community and local authorities, which helped in rebuilding the production facility. It took several years to fully recover, but Marshall Pottery managed to bounce back and continue its operations.

What are some of the famous products of Marshall Pottery?

Marshall Pottery is known for its wide range of stoneware products. Some of its famous products include large ceramic pots for outdoor plants, handmade kitchenware such as bowls and mugs, and decorative items like vases and candleholders.