Woodworking is a craft that has been around for centuries. Whether you’re a beginner or an experienced woodworker, understanding the various techniques and joinery methods is essential to creating high-quality and functional pieces. One such technique that every woodworker should be familiar with is the rabbet joint.

A rabbet is a groove or channel that is cut into the edge or face of a piece of wood. This joint is commonly used to create a flush surface when joining two pieces of wood together. It is a versatile joint that can be used in a variety of applications, from constructing cabinets and drawers to creating frames and trim.

There are several types of rabbet joints, each with its own purpose and method of construction. The basic rabbet joint involves cutting a groove along the edge of one piece of wood and fitting it into a corresponding groove in the other piece. This creates a strong and clean joint that can be further reinforced with glue or screws.

The rabbet joint is often used in conjunction with other joinery techniques, such as dado joints and miter joints, to create more complex and precise connections. It is an essential skill for any woodworker to master, as it allows for greater versatility and flexibility in creating woodworking projects.

Whether you’re a beginner or an experienced woodworker, understanding and utilizing rabbets in your woodworking projects can greatly enhance the quality and functionality of your creations. By incorporating this versatile joint into your repertoire, you’ll be able to create stronger, more seamless connections between pieces of wood, resulting in a finished product that is not only visually appealing but also structurally sound.

What are Rabbets?

A rabbet is a type of groove or recess cut into the edge or end of a piece of wood. It is typically used to create a joint or to provide a place for another piece of wood to fit into. Rabbets can be found in various woodworking projects and are commonly used in cabinetmaking, bookshelf construction, and furniture-making.

Rabbets are usually cut using a table saw, router, or handheld chisel. The width and depth of the rabbet can vary depending on the specific application and the size of the materials being used. They can be simple and shallow or wide and deep, depending on the intended purpose.

Rabbets are often used for joinery, allowing pieces of wood to fit together tightly. By cutting a rabbet in one board and inserting the matching protrusion, called a tenon, on another board, a strong and secure joint can be created. Rabbets can also be used to create a recessed area in a piece of wood to hold panels, glass, or other materials.

One key advantage of using rabbets is that they hide the joint, creating a clean and seamless appearance. By recessing the joint, the edges of the two pieces of wood overlap, providing a more polished look.

Rabbets can also be used to create a channel for decorative purposes. This can be seen in projects such as picture frames or boxes where a decorative inlay or strip is inserted into the rabbet groove.

Overall, rabbets are versatile and essential in various woodworking projects. Whether it’s for joining pieces together or creating a recessed area, rabbets provide a practical solution for strong and visually appealing woodworking joints.

Why are Rabbets Important in Woodworking?

Rabbets are an essential component in woodworking and serve multiple important purposes. They are commonly used in various woodworking projects and are particularly useful for creating strong and seamless joints, adding depth to a piece, and accommodating other components.

1. Strong Joints: One of the primary reasons rabbets are important in woodworking is their ability to create strong joints. When two pieces of wood are joined by overlapping their edges and creating a rabbet, it provides a larger surface area for gluing or nailing, resulting in a more secure and durable joint. This is especially beneficial when constructing things like boxes, drawers, or frames where strength and stability are crucial.

2. Depth and Dimension: Rabbets can add depth and dimension to a woodworking project. By creating recessed areas, rabbets allow for the insertion of other components such as glass, panels, or trim. This creates visual interest and can enhance the overall appearance of the finished piece. Rabbets can also be used to conceal the edges of plywood or other materials, providing a clean and finished look.

3. Accommodating Components: Rabbets are frequently used to accommodate other components within a woodworking project. For example, they can be used to create a space for hinges, drawer slides, or decorative moldings. This allows these components to be seamlessly incorporated into the design, providing functionality and aesthetic appeal.

4. Versatility: Rabbets are versatile and can be created using various tools and techniques. They can be cut using hand tools, such as a chisel or router plane, or power tools, such as a table saw or router. This versatility allows woodworkers to choose the most appropriate method based on their skill level, available tools, and project requirements.

In conclusion, rabbets are important in woodworking due to their ability to create strong joints, add depth and dimension, accommodate components, and their versatility. Understanding how to create and use rabbets can greatly enhance a woodworker’s capabilities and result in well-crafted and visually appealing projects.

Understanding Rabbet Joints

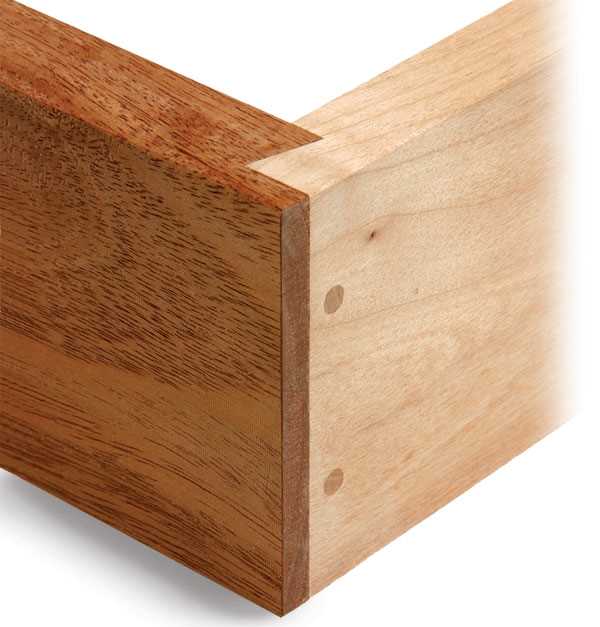

Rabbet joints are a common type of joint used in woodworking. They are formed by cutting a groove or recess along the edge or face of a piece of wood, allowing another piece of wood to fit into the recess. Rabbet joints are primarily used for joining two pieces of wood at a right angle or for creating a flush surface between two components.

Types of Rabbet Joints

There are several variations of rabbet joints, each with its own specific purpose:

- Simple Rabbet Joint: This is the most basic type of rabbet joint, where a single groove is cut along one edge of the wood. It is commonly used for joining two pieces of wood together.

- Rebate Joint: Also known as a stopped rabbet joint, this type of joint has a groove that does not extend to the end of the wood. It provides a hidden recess for the joining piece, resulting in a more concealed joint.

- Double Rabbet Joint: As the name suggests, this joint involves cutting two rabbet grooves on two adjacent edges of the wood. It is commonly used for creating a frame with overlapping corners, such as a picture frame.

- Tongue and Rabbet Joint: In this joint, a tongue is cut along the edge of one piece of wood, which fits into a corresponding groove (rabbet) in the other piece. It provides additional strength and alignment to the joint.

Advantages of Rabbet Joints

Rabbet joints offer several advantages in woodworking:

- Strength: The interlocking design of rabbet joints provides increased strength and stability to the joint. This makes them suitable for bearing heavy loads or for joining structural components.

- Alignment: Rabbet joints help in aligning the two pieces of wood accurately, ensuring a flush and seamless joint.

- Concealed Joints: Depending on the type of rabbet joint used, the joint can be made less visible, resulting in a cleaner and more professional appearance.

- Easy Assembly: Rabbet joints are relatively easy to assemble, requiring fewer steps compared to other more complex joints.

Applications of Rabbet Joints

Rabbet joints are commonly found in various woodworking projects, including:

- Cabinetmaking: Rabbet joints are frequently used in constructing cabinets, drawers, and other furniture pieces.

- Box making: Rabbet joints provide a strong and secure joint for making boxes, such as jewelry boxes or storage containers.

- Frame construction: Rabbet joints are used in creating frames for pictures, mirrors, or windows.

- Door and window construction: Rabbet joints are often employed in the construction of doors and windows, providing structural strength and improved weather resistance.

Overall, understanding rabbet joints is essential for any woodworker as they are versatile, strong, and widely used in various woodworking applications.

Types of Rabbet Joints

Rabbet joints are a popular type of joint used in woodworking. They are commonly used to join two pieces of wood together at a right angle. There are several types of rabbet joints, each with its own unique characteristics and uses. Here are some of the most common types:

- Open rabbet: This type of rabbet joint is cut along the edge of a piece of wood, leaving a recess or groove. It is often used to create a decorative profile or to hold a panel in place.

- Stopped rabbet: In this type of rabbet joint, the groove is stopped before reaching the end of the wood, creating a shoulder. It is commonly used for drawer construction or when a clean, finished look is desired.

- Double rabbet: A double rabbet joint consists of two grooves cut parallel to each other on the edge of a piece of wood. It is often used to join two pieces of wood together to create a stronger and more secure joint.

- Spline rabbet: This type of rabbet joint involves cutting a groove along the edge of a piece of wood and inserting a separate spline or tongue into the groove to create a stronger joint.

Rabbet joints can be made using different tools, such as a table saw, router, or chisel, depending on the desired outcome and the woodworker’s preference. They are versatile joints that provide strength and stability to woodworking projects.

How to Make Rabbet Joints

Creating rabbet joints in woodworking involves a few simple steps. Here is a step-by-step guide to making rabbet joints:

- Measure and mark the wood: Start by measuring and marking the depth and width of the rabbet joint on the edge or end of the piece of wood. Use a measuring tape and a pencil to make accurate markings.

- Set up the table saw: Adjust the height of the blade on your table saw to the desired depth of the rabbet. Use a push stick or a push block for safety.

- Set the fence: Set the fence on your table saw to the desired width of the rabbet. Use a tape measure or a miter gauge to ensure accurate measurements.

- Cut the rabbet: Place the marked wood against the fence and run it through the table saw. Make sure to keep the wood firmly against the fence for a straight and clean cut. Repeat this step for all the pieces of wood that require rabbet joints.

- Test fit the joints: After making the rabbet cuts, test fit the joints by placing the pieces of wood together. Ensure a proper fit and make any necessary adjustments to the depth or width of the rabbet if needed.

- Secure the joints: Once the joints fit properly, apply wood glue to the rabbet surfaces and align the pieces of wood together. Use clamps to hold the joints in place until the glue dries, following the manufacturer’s instructions for drying time.

- Finish the joint: After the glue is dry, sand any rough edges or imperfections on the joint. Apply a finish or paint if desired to enhance the appearance and protect the wood.

By following these steps, you can easily create rabbet joints that are strong and secure, adding strength and stability to your woodworking projects.

Using Rabbets for Joinery

Rabbets are a versatile woodworking joint that can be used in various applications, providing a strong and clean connection between two pieces of wood. Here are some common uses of rabbets for joinery:

- Joining two boards: Rabbets can be used to join two boards at right angles, creating a strong and neat corner. The rabbet can be cut on the end of one board and the side of the other, allowing for a flush and seamless connection.

- Creating a rabbet joint: Two pieces of wood can be joined using a rabbet joint, where a rabbet is cut along the edge of one piece and a corresponding groove is cut on the edge of the other. This type of joint provides a larger gluing surface area, improving the strength of the connection.

- Installing a back panel: Rabbets are commonly used to install back panels on cabinets or bookshelves. By cutting rabbets along the inside edges of the cabinet or shelf, the panel can be fitted securely into place, providing added stability and support.

- Constructing drawers: Rabbets are often used in drawer construction to join the sides of the drawer to the front and back panels. By cutting rabbets along the inside edges of the front and back panels, the sides of the drawer can be easily attached, creating a strong and sturdy drawer box.

When using rabbets for joinery, it’s important to ensure accurate measurements and precise cuts to achieve a tight fit. A table saw or router with a rabbeting bit is commonly used to cut rabbets, but hand tools such as chisels can also be used for smaller projects or intricate detailing.

Overall, rabbets offer a reliable and straightforward solution for joinery in woodworking projects. By understanding the different applications and techniques for using rabbets, woodworkers can achieve professional and durable connections in their projects.

Strength and Stability of Rabbet Joints

Rabbet joints are known for their exceptional strength and stability, making them an ideal choice for many woodworking projects. The design of a rabbet joint allows for a tight and secure fit between two pieces of wood, creating a strong bond that can withstand significant pressure and weight.

The strength of a rabbet joint comes from the large gluing area it provides. The wide contact area between the mating surfaces of the joint allows for a greater amount of glue to be applied, resulting in a stronger bond. This increased glue surface also helps distribute the load evenly across the joint, reducing the risk of stress concentration and potential failure.

In addition to their strength, rabbet joints also offer excellent stability. The interlocking nature of the joint prevents the pieces of wood from shifting or separating under normal use. This stability is particularly beneficial in applications where the joint may be subjected to constant movement or heavy loads, such as in doors, cabinets, or furniture.

Furthermore, rabbet joints provide a degree of protection against lateral forces. The shoulders of the rabbet joint help prevent the wood from being pushed apart or pulled apart sideways, providing additional stability and resistance against external forces.

It is important to note that the overall strength and stability of a rabbet joint also depend on the quality of the materials used and the precision of the joint itself. Proper sizing, fitting, and gluing techniques are essential to ensure optimal performance and longevity of the joint.

| Strength | Rabbet joints provide exceptional strength due to the wide gluing area and increased bond between mating surfaces. |

| Stability | The interlocking nature of rabbet joints prevents shifting or separation of wood pieces, ensuring stability. |

| Protection | The shoulders of rabbet joints offer resistance against lateral forces, protecting the joint from being pushed or pulled apart sideways. |

Overall, rabbet joints are a reliable and durable option for joining wood pieces together. Their strength, stability, and protection against lateral forces make them a popular choice among woodworkers for a wide range of applications.

Applications of Rabbet Joints in Woodworking Projects

The rabbet joint is a versatile woodworking joint that is used in various applications. Its design allows for a strong and secure connection between two pieces of wood. Here are some common applications of rabbet joints in woodworking projects:

- Joining Cabinet Components: Rabbet joints are frequently used to join the sides, top, and bottom panels of cabinets. The rabbets are cut along the edge of the panels, creating a groove that allows the panels to fit securely together.

- Creating Drawer Boxes: Rabbet joints are commonly used to create the corners of drawer boxes. The rabbets are cut along the edges of the drawer sides, allowing them to slot into the front and back panels. This creates a strong and sturdy construction for the drawer.

- Building Bookcases and Shelves: Rabbet joints are often used to join the sides and back panel of bookcases and shelves. The rabbets are cut along the edges of the panels, providing a secure connection that can withstand the weight of books and other objects.

- Constructing Picture Frames: Rabbet joints are a popular choice for constructing picture frames. The rabbets are cut along the edges of the frame components, allowing the glass and artwork to fit securely within the frame.

- Building Window Frames: Rabbet joints are commonly used in window frame construction. The rabbets are cut along the edges of the frame components, providing a strong connection that can withstand the stresses of opening and closing windows.

- Creating Furniture Frames: Rabbet joints are often used in furniture construction to create frames. Whether it’s a chair, table, or cabinet, rabbet joints can provide a strong and secure connection between the various components of the furniture.

Overall, rabbet joints are a valuable technique in woodworking projects. Their versatility and strength make them an essential part of many woodworking applications.

FAQ:

What is a rabbet in woodworking?

A rabbet is a recess or groove cut into the edge of a piece of wood, usually to receive another piece of wood or to serve as a joint or connection.

What tools are commonly used to create a rabbet?

Common tools used to create a rabbet include a router, table saw, dado set, and chisel.

What is the purpose of a rabbet joint?

The purpose of a rabbet joint is to provide a strong, flush connection between two pieces of wood.

What are some common applications of rabbets in woodworking?

Rabbets are commonly used for cabinet making, picture frame construction, drawer construction, and door and window construction.

Are there different types of rabbets?

Yes, there are several different types of rabbets, including single rabbet, double rabbet, and stopped rabbet.