Woodworking is an ancient craft that has been practiced for centuries. One of the fundamental concepts in woodworking is understanding the kerf. The kerf refers to the width of the cut made by a saw blade or other cutting tool. It plays a crucial role in the overall design and function of the finished piece.

In woodworking, the kerf is not just a simple cut in the wood. It is a carefully calculated measurement that affects the fit, joinery, and overall stability of the final product.

One of the primary functions of the kerf is to allow for the removal of material during the cutting process. The width of the kerf determines how much material will be removed, which in turn affects the accuracy and precision of the cut. A wider kerf allows for more material to be removed, resulting in a larger gap between the two pieces being joined. Conversely, a narrower kerf allows for less material to be removed, resulting in a tighter and more precise fit.

The kerf also plays a role in the overall strength and stability of the finished piece. A wider kerf can weaken the structural integrity of the wood, making it more prone to splitting or warping over time. On the other hand, a narrower kerf provides better support and stability, resulting in a more durable and long-lasting product.

Understanding the kerf is essential for woodworkers of all skill levels. By carefully considering the width of the kerf and its impact on fit, joinery, and stability, woodworkers can achieve the desired results and create pieces that are not only visually stunning but also structurally sound.

In conclusion, the kerf is a central concept in woodworking that affects the design, function, and overall quality of a finished piece. Its width determines the amount of material removed, the fit and joinery, as well as the strength and stability of the final product. Woodworkers must understand the role of the kerf in order to create pieces that are both visually appealing and structurally sound.

The Basics of Kerf

Kerf is a term commonly used in woodworking to refer to the width of the cut made by a saw blade or cutting tool. It is an essential concept to understand when working with wood, as it directly impacts the fit and finish of the final product.

Definition:

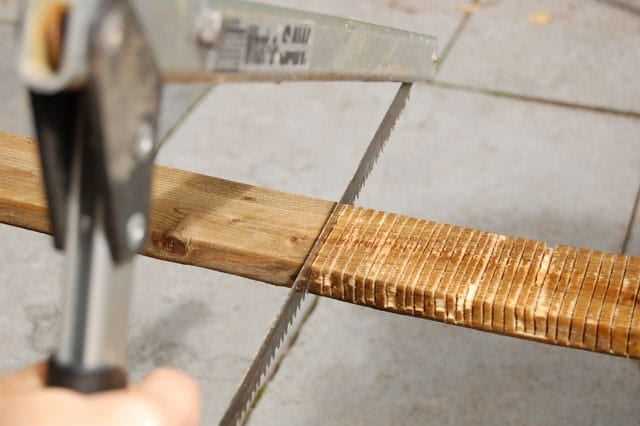

The kerf is the space left by the saw blade as it cuts through the wood. It is measured as the width of the cut, typically in millimeters or fractions of an inch. A wider kerf results in a larger cut, while a narrower kerf creates a smaller cut.

Functions of Kerf:

- Clearance: The primary function of the kerf is to provide clearance for the saw blade or cutting tool. The width of the kerf allows the blade to move freely through the wood without binding or getting stuck.

- Waste Removal: The kerf also facilitates waste removal by creating a space for the sawdust and wood chips to escape. As the blade cuts through the wood, the kerf acts as a channel, allowing the waste material to be expelled from the cut.

- Fit and Finish: The size of the kerf directly affects the fit and finish of the final product. A wider kerf can lead to looser joints and gaps, while a narrower kerf creates tighter and more precise cuts.

Applications:

The knowledge of kerf is crucial in various woodworking applications, including:

- Joinery: When creating joinery, such as mortise and tenon or dovetail joints, understanding the kerf is essential for achieving proper fit and strength.

- Cutting: Whether using a hand saw or power tools like a table saw or bandsaw, knowing the kerf width helps determine the accuracy and efficiency of the cutting process.

- Material Optimization: Understanding the kerf allows woodworkers to calculate the amount of material needed for a project, minimizing waste and maximizing efficiency.

In conclusion, kerf is a fundamental concept in woodworking that refers to the width of the cut made by a saw blade or cutting tool. It serves multiple functions, including providing clearance for the blade, facilitating waste removal, and influencing the fit and finish of the final product. Being aware of the kerf is essential for achieving precise and accurate cuts in various woodworking applications.

The Importance of Kerf in Woodworking

The kerf is an essential element in woodworking that plays a critical role in achieving precise and accurate cuts. It refers to the width of the cut made by a saw or any cutting tool. Understanding the importance of kerf is crucial for woodworkers as it impacts the overall quality and fit of the woodwork project.

One of the primary functions of the kerf is to ensure that the saw blade or cutting tool can pass through the wood without creating too much friction or resistance. The width of the kerf determines the amount of material that the saw blade removes from the wood, resulting in the separation of two pieces.

By choosing the appropriate saw blade thickness and set, woodworkers can control the width of the kerf, allowing for more accurate cuts. Too narrow of a kerf can cause binding or sticking of the blade, leading to inaccurate cuts, while too wide of a kerf may result in excess material removal and weak joints.

The kerf also affects the fit of joinery in woodworking projects. For example, when creating dovetail joints, the width of the kerf determines the tightness and strength of the joint. A perfectly sized kerf ensures a precise fit, while an incorrectly sized kerf may result in loose or weak joints.

Furthermore, the kerf impacts the overall efficiency of the woodworking process. A wider kerf requires more time and effort to cut through the wood, while a narrower kerf allows for faster and more efficient cuts. By understanding the optimal kerf width for different types of wood and cutting tasks, woodworkers can improve their productivity and achieve better results.

In addition to its functional importance, the kerf can also add aesthetic value to woodworking projects. By carefully selecting the width and alignment of the kerf, woodworkers can create decorative effects, such as patterns or grooves, enhancing the visual appeal of the final piece.

In conclusion, the kerf plays a vital role in woodworking, impacting the accuracy, fit, efficiency, and aesthetics of the finished product. By understanding the importance of kerf and making informed decisions about its width and alignment, woodworkers can achieve superior results and elevate their craftsmanship.

Types of Kerf

There are several types of kerf that can be used in woodworking, each serving a different purpose. These include:

- Straight Kerf: This is the most common type of kerf and is used for straight cuts in woodworking projects. It creates a clean and straight line in the wood.

- Curved Kerf: A curved kerf is used when making curved cuts in wood. This type of kerf allows the wood to be shaped into various curves and designs.

- Dado Kerf: A dado kerf is a wider and deeper cut that is used to create a groove or joint in the wood. It is often used in cabinetry and furniture making to join pieces of wood together.

- Rabbet Kerf: A rabbet kerf is similar to a dado kerf, but it is made along the edge of the wood instead of in the middle. It is typically used to create a recessed area for a joint or to add dimension to a project.

- Biscuit Kerf: A biscuit kerf is a small and shallow cut that is made to accommodate a wooden biscuit. Biscuits are used to join two pieces of wood together and provide added strength to the joint.

Each type of kerf has its own unique purpose and application in woodworking. Understanding the different types of kerf can help woodworkers choose the right tool and technique for their specific project.

Tools and Techniques for Creating Kerf

The creation of kerf in woodworking requires specific tools and techniques to achieve the desired results. Here are some common tools and techniques used to create kerf:

1. Saw Blades

- Thin kerf saw blades: These blades have a narrow cutting width, typically ranging from 0.090 to 0.125 inches. They are specifically designed for creating narrow kerfs.

- Dado blades: These blades consist of two or more circular blades stacked together. They are used to create wider kerfs, often used for joinery and dado cuts.

2. Table Saw

The table saw is a versatile woodworking tool used to make precise cuts. To create kerf with a table saw, the wood is passed through the blade at a specific height and angle, resulting in a groove or slot.

3. Router

Routers equipped with specific bits can be used to create kerf in woodworking. By adjusting the depth and width of the cut, the router can create precise kerfs with clean edges.

4. Miter Saw

A miter saw, also known as a chop saw or a drop saw, can be used to create angled or straight kerf cuts. By adjusting the angle and height of the saw blade, precise kerfs can be made.

5. Chisels

Chisels are hand tools used to make small or intricate kerf cuts. By striking the chisel with a mallet or hammer, controlled and precise kerf cuts can be achieved.

6. Laser-Cutters

Modern technology has introduced laser-cutters capable of creating kerfs in wood. These machines use a laser beam to burn or melt the wood, resulting in precise kerf cuts.

7. Bandsaw

The bandsaw is a power tool consisting of a continuous band of toothed metal stretched between two or more wheels. It can be used to create straight or curved kerfs by guiding the wood through the saw blade.

8. Hand-Saws

Hand saws, such as coping saws and dovetail saws, can be used to create small or intricate kerf cuts by hand. These hand tools offer more control and precision for specific woodworking projects.

Overall, creating kerf in woodworking requires a combination of the right tools and techniques. From traditional hand tools to modern machinery, there are various options available for achieving the desired kerf cuts and grooves in wood.

Kerf in Joinery: Enhancing Strength and Stability

When it comes to joinery, the kerf plays an important role in enhancing the strength and stability of wood constructions. The kerf refers to the groove or slot created by a saw blade while cutting into the wood. It may seem like a small detail, but its impact on the overall quality of joinery work cannot be overlooked.

Improved Glue Adhesion:

One of the main reasons why the kerf is important in joinery is its role in improving glue adhesion. When wood pieces are joined together using glue, the kerf provides a larger surface area for the adhesive to bond to. The tight fit of the mating pieces created by the kerf ensures that the glue distributes evenly and creates a strong bond between the wood pieces.

Preventing Wood Movement:

In addition to enhancing glue adhesion, the kerf also helps prevent wood movement within a joint. Wood is a natural material that expands and contracts with changes in humidity and temperature. Without the kerf, these movements can put stress on the joint, causing it to weaken or even fail over time. The kerf allows the wood to expand and contract without affecting the strength of the joint, ensuring long-term stability.

Reinforcing Joints:

Furthermore, the kerf can be used strategically to reinforce joints and provide additional strength. By cutting kerfs along the length of the joint, known as splines or keys, the surface area for glue adhesion increases, creating a stronger bond between the pieces. The kerf also acts as a mechanical reinforcement, preventing the joint from separating under stress.

Creating Hidden Joints:

The kerf can also be utilized to create hidden joints, where the connection between two pieces is concealed from view. By making precision cuts with a thin kerf, such as with a dovetail joint or a tongue and groove joint, the joint can be hidden within the wood surface, resulting in a clean and seamless appearance.

Conclusion:

In conclusion, the kerf plays a crucial role in joinery by enhancing the strength and stability of wood constructions. Its ability to improve glue adhesion, prevent wood movement, reinforce joints, and create hidden connections makes it an essential element in the world of woodworking. Whether you are a beginner or an experienced woodworker, understanding and utilizing the kerf effectively will undoubtedly lead to stronger and more durable joinery work.

Kerf and Design: Adding Dimension and Texture

The kerf, or the width of the cut made by a saw or blade, can be an important design element in woodworking. By manipulating the kerf, woodworkers can add dimension and texture to their projects, enhancing the overall aesthetic appeal and creating unique visual effects.

One way to utilize the kerf for design purposes is by incorporating it into joinery techniques such as dovetail or finger joints. By adjusting the width of the kerf, woodworkers can create a snug fit that adds strength and stability to the joint. Additionally, the visible kerf lines can serve as decorative elements, adding visual interest and highlighting the craftsmanship of the piece.

Another technique that takes advantage of the kerf is known as kerf bending. By strategically cutting kerfs along the length of a piece of wood, it becomes more flexible and can be curved or bent into different shapes. This technique is often used in the creation of curved furniture or decorative accents, allowing woodworkers to achieve unique and intricate designs that would be difficult or impossible using traditional bending methods.

The kerf can also be used to create texture on the surface of wood. By varying the depth or angle of the kerf, woodworkers can create patterns, lines, or even three-dimensional effects. This adds visual interest and tactile appeal to the piece, making it more engaging and unique.

When working with kerf for design purposes, it is important to consider the type of saw or blade being used. Different types of saws, such as a table saw or a bandsaw, produce different kerf widths and qualities. Woodworkers should choose the appropriate tool for their desired effect, ensuring that the kerf aligns with the overall design vision.

In conclusion, the kerf can be a versatile and valuable tool in woodworking design. By understanding its functions and applications, woodworkers can utilize the kerf to add dimension, texture, and visual interest to their projects, creating unique and visually appealing pieces.

Kerf in Woodworking Projects: Applications and Examples

The kerf, or the width of the cut made by a saw blade, plays a crucial role in woodworking projects. Understanding the applications and examples of kerf can help woodworkers achieve precise and accurate cuts in their projects.

1. Joinery: Kerf can be used in various joinery techniques to create tight and strong connections between wood pieces. For example, a dado joint involves cutting a groove in one piece of wood that exactly matches the width of the second piece of wood, allowing for a seamless and secure connection. By considering the kerf width, woodworkers can ensure a precise fit for the joint.

2. Wood bending: Kerf cuts can be strategically made in the backside of a piece of wood to make it more flexible and easier to bend. By cutting evenly spaced kerfs along the length of the wood, woodworkers can create beautiful curved shapes and designs. This technique is often used in projects such as making curved chair backs or decorative wooden panels.

3. Inlays and marquetry: Kerf can be used to create channels or grooves in wood to accommodate decorative inlays or marquetry pieces. By carefully cutting kerfs to the desired depth and width, woodworkers can seamlessly integrate intricate designs or patterns into their projects. This technique adds a touch of elegance and intricacy to woodworking projects.

4. Cutting services: Understanding the kerf width is essential when working with professional cutting services. Whether using a CNC machine or laser cutter, the kerf width needs to be taken into account to ensure accurate measurements and proper fitting of wood pieces. By providing the correct kerf width information, woodworkers can ensure precise and high-quality cuts in their projects.

5. Veneering: Kerf cuts can be made on the backside of a veneer to assist in the bending and conforming of the veneer to curved surfaces. By strategically placing kerf cuts, woodworkers can achieve smooth and seamless veneer application on complex shapes and curves.

In conclusion, understanding the applications and examples of kerf in woodworking projects is crucial for achieving precise cuts and creating intricate designs. By considering the kerf width, woodworkers can enhance the quality and aesthetics of their projects, whether it be through joinery techniques, wood bending, inlays and marquetry, working with cutting services, or veneering.

FAQ:

What is the kerf in woodworking?

The kerf in woodworking refers to the width of the cut made by a saw blade or other cutting tool in the wood.

What functions does the kerf serve in woodworking?

The kerf serves several functions in woodworking. It allows for the removal of material, creates a path for the blade, and helps to prevent the wood from binding and splintering.

Why is understanding the kerf important in woodworking?

Understanding the kerf is important in woodworking because it helps woodworkers to accurately plan and design their projects. It also allows them to make precise cuts and ensures that the final result fits together properly.

How does the kerf affect the fit of joinery in woodworking?

The kerf can have a significant impact on the fit of joinery in woodworking. If the kerf is too wide, the joints may be loose and weak. If the kerf is too narrow, the joints may be tight and difficult to assemble.

What are some common applications of the kerf in woodworking?

The kerf is used in a variety of applications in woodworking. It is used to make straight cuts, create internal or external curves, and even to make decorative patterns in the wood.