Creating pottery is a beautiful and rewarding art form that allows you to express your creativity. One essential element of pottery is the handle, which not only adds functionality but also adds aesthetics to your piece. Whether you are a beginner or an experienced potter, making handles for pottery is a skill that you can easily learn and master. In this step-by-step guide, we will walk you through the process of making handles for your pottery.

Step 1: Preparation

Before you start making handles, it is important to prepare your materials and tools. You will need clay, a rolling pin, a knife or clay cutting wire, a sponge, and a bowl of water. Make sure your work area is clean and that you have enough space to comfortably work on your pottery.

Step 2: Creating the Base

The handle needs a stable base to attach to the pottery. Begin by rolling out a piece of clay to your desired thickness using the rolling pin. Cut the clay into a long strip using a knife or a clay cutting wire. The length of the strip will depend on the size of your pottery, so make sure to measure it accordingly.

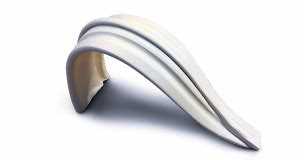

Pro Tip: If you want a curved handle, shape the strip of clay into the desired curve before attaching it to your pottery.

Step 3: Attaching the Handle

Dip your sponge in water and moisten the area on your pottery where you want to attach the handle. Press one end of the strip firmly onto the dampened area, making sure it is securely attached. Use your fingers to smooth out any rough edges or air bubbles.

Step 4: Shaping and Finishing

Now that the handle is attached, you can shape it according to your desired design. Use your fingers to gently mold the clay, adding curves or bends as needed. Once you are satisfied with the shape, use a sponge or a wet cloth to smooth out the surface and remove any excess clay or imperfections.

Step 5: Drying and Firing

Allow the pottery with the newly attached handle to dry completely. This may take several days or even weeks depending on the thickness of the clay. Once dry, you can then fire your pottery in a kiln according to the specific instructions for your clay.

Now that you know the step-by-step process of making handles for pottery, you can start incorporating this skill into your own pottery creations. With practice and experimentation, you will be able to create unique and beautiful handles that complement your pottery and showcase your artistic vision.

Preparing the Clay

Before you can start making handles for pottery, you need to prepare the clay. Here are the steps to follow:

- Gather your materials: You will need a ball of clay, a rolling pin, a ruler, a knife or clay cutting wire, and a damp sponge.

- Knead the clay: Start by kneading the clay to remove any air bubbles and make it easier to work with. Use your hands to press and fold the clay, rotating it as you go, until it feels smooth and pliable.

- Shape the clay: Once the clay is kneaded, shape it into a round ball. Use your hands to gently flatten the top and bottom of the ball.

- Prepare the work surface: Sprinkle a small amount of water on your work surface to prevent the clay from sticking. Place the clay ball in the center of the surface.

- Roll out the clay: Use the rolling pin to flatten the clay into a slab. Roll back and forth, starting from the center and working your way outwards, until the slab is of uniform thickness.

- Trim the edges: Use a ruler and a knife or clay cutting wire to trim the uneven edges of the slab, creating a neat rectangle or square shape.

- Smooth the surface: Use a damp sponge to gently smooth the surface of the slab, removing any imperfections or rough areas. This will make it easier to attach the handle later on.

Once you have prepared the clay, you are ready to start making handles for pottery. The next step is to create the handle shape and attach it to your pottery piece.

Rolling the Clay into Long Tubes

To make handles for pottery, you’ll first need to roll the clay into long tubes. This will serve as the base for shaping and attaching the handles to your pots. Follow these steps to roll your clay into long tubes:

-

Start by preparing your clay. Ensure that it is properly wedged and soft enough to work with. Remove any air bubbles by kneading the clay gently.

-

Take a small amount of clay (about the size of a tennis ball) and roll it into a ball using the palms of your hands. Make sure the clay is smooth and free from cracks or imperfections.

-

Flatten the clay ball slightly by gently pressing it down on a clean, smooth surface. This will make it easier to roll it into a long tube.

-

Place your hands on both ends of the flattened clay ball, with your fingers parallel to each other. Apply even pressure and start rolling the clay back and forth, moving your hands in opposite directions. This will gradually lengthen the clay and shape it into a tube.

-

Continue rolling until the clay reaches the desired length for your handle. Keep in mind that the handle may shrink slightly during the drying and firing process, so it’s better to make it slightly longer than needed.

-

Once you have rolled the clay into a long tube, use a wire tool or a sharp knife to cut it into the desired length for your handle. Smooth the cut ends with your fingers to remove any rough edges.

-

Repeat these steps to roll and cut additional tubes if you need more handles for your pottery.

Remember to keep your clay moist while working with it to prevent it from drying out too quickly. You can mist it with water or cover it with a damp cloth when not in use. Rolling the clay into long tubes is an essential step in creating handles for your pottery, so take your time and make sure the tubes are smooth and even. With practice, you’ll be able to create beautiful and functional handles for your ceramic creations.

Shaping the Handles

Once you have prepared your clay and gathered all the necessary tools, you are ready to start shaping the handles for your pottery.

Follow these steps to create well-shaped and sturdy handles:

- Measure and cut the clay: Determine the desired length and width of your handle. Use a cutting tool to measure and cut the clay to the appropriate size.

- Knead and roll the clay: Take the cut clay piece and knead it gently to remove any air pockets. Then, use your hands to roll the clay into a long snake-like shape. The thickness can vary depending on the desired handle style.

- Smooth and refine the shape: Gently roll the clay snake between your hands to smooth out any rough edges or inconsistencies. Pay attention to the ends of the handle to achieve a tapered shape, if desired.

- Attach the handle to the pottery: Decide where you want to place the handle on your pottery piece. Score and slip both the pottery and the handle where they will join. Press the handle onto the scored area and gently smooth out any visible seams.

- Support and shape the handle: In order to maintain the desired shape of the handle and prevent it from drooping or collapsing while drying and firing, use support tools like foam or newspaper to prop up the handle. You can also gently shape the handle while it is still malleable to achieve your desired look.

- Avoid overworking the handle: While shaping the handle, avoid excessive handling or stretching, as it can weaken the clay and cause it to crack or break. If necessary, wet your fingers or use a bit of water on the clay to make it more malleable.

- Allow the handle to dry: Once you are satisfied with the shape and placement of the handle, set your pottery piece aside to dry. Take care not to disturb or accidentally touch the handle as it dries, as it may lose its shape or detach from the pottery.

Attaching the Handles to the Pottery

Once you have created your handles, it’s time to attach them to your pottery. Here is a step-by-step guide on how to do it:

- Prepare your pottery: Before attaching the handles, make sure your pottery is dry and free from any dust or debris. This will ensure a strong bond between the handle and the pottery.

- Apply slip: Slip is a mixture of clay and water that acts as a glue when wet. Apply a thin layer of slip to the area of the pottery where the handle will be attached.

- Position the handle: Gently place the handle onto the pottery, making sure it is aligned properly. Press it firmly against the pottery to ensure a good bond.

- Score the handle: Using a scoring tool or the tines of a fork, create cross-hatch marks on both the handle and the pottery. This roughens up the surface and allows the slip to adhere better.

- Apply more slip: Apply a little more slip on top of the scored area on both the handle and the pottery.

- Secure the handle: Press the handle firmly onto the pottery again, making sure it is securely attached. Smooth out any excess slip that may have squeezed out.

- Support the handle: To prevent the handle from sagging or falling while drying and firing, use props or supports to keep it in place. This will help maintain the desired shape of the handle.

- Repeat for other handles: If your pottery has multiple handles, repeat the previous steps for each additional handle.

- Allow it to dry: Once the handles are securely attached, set aside the pottery to dry completely. This may take a few days or longer, depending on the thickness of the clay.

- Bisque fire: After the pottery is dry, bisque fire it in a kiln. The handles should be able to withstand the firing process without coming loose if they were properly attached.

Following these steps will ensure that your pottery handles are securely attached and will withstand the drying and firing process. Remember to handle your pottery with care, especially when applying pressure to attach the handles, to avoid any accidental damage.

Smoothing and Finishing the Handles

After you have attached the handles to your pottery, it’s important to smooth and finish them to ensure they are comfortable to hold and visually appealing.

Here are the steps to smoothly finish your pottery handles:

- Trim any excess clay: Use a trimming tool or a sharp knife to carefully remove any excess clay from the handle. This will help refine and shape the handle.

- Smooth the surface: Wet your fingers or use a sponge to gently smooth the surface of the handle. This will help remove any imperfections and make it more comfortable to hold.

- Add texture or decoration: If desired, you can add texture or decorate the handle using various tools or techniques. This can be done by creating patterns, carving designs, or adding slip or underglaze.

- Check for any cracks or weak spots: Inspect the handle carefully to ensure there are no cracks or weak spots. If you notice any, you may need to reinforce them with additional clay or repair them before firing.

- Let it dry: Allow the handles to dry completely before firing. This will ensure that they maintain their shape and prevent any mishaps during the firing process.

Remember, the process of smoothing and finishing your handles is just as important as creating them. It adds the final touch to your pottery and can greatly enhance its overall quality and appearance.

Drying the Pottery

After you have finished shaping and smoothing out your pottery handles, it’s time to let them dry. The drying process is crucial as it helps to remove moisture from the clay and prepare it for kiln firing.

Here are the steps to properly dry your pottery handles:

- Air drying: Place your pottery handles on a clean, flat surface where they can receive air circulation from all sides. It is important to avoid direct sunlight, as it can cause uneven drying and increase the risk of cracking. Allow the handles to air dry for about 24-48 hours, depending on the thickness of the clay.

- Flip and rotate: To ensure even drying, flip the handles over after the first 24 hours. Additionally, you can rotate them to different positions to promote uniform moisture evaporation. This step helps to minimize warping and cracking.

- Use fans or a dehumidifier: If you are working in a humid environment or need to speed up the drying process, you can use fans or a dehumidifier to create airflow and reduce moisture. However, be careful not to place the handles too close to the airflow, as it can cause rapid drying and cracking.

- Check for moisture: To ensure that the handles are completely dry, you can touch them or use a moisture meter. If they feel cool to the touch or show a high moisture reading, give them more time to dry.

Remember, rushing the drying process can lead to cracks and other defects in your pottery handles. It’s important to be patient and allow the handles to dry slowly and evenly. Once they are fully dry, you can proceed to the firing process.

Firing the Pottery in the Kiln

Firing your pottery in a kiln is an important step in the pottery-making process. The firing process helps to harden the clay and make it permanent, ensuring that your pottery is durable and functional. Here is a step-by-step guide on how to fire your pottery in the kiln:

- Preparation: Before firing your pottery, make sure it is completely dry. Any moisture left in the clay can cause it to crack or explode in the kiln. Inspect the pottery to ensure there are no air bubbles or other imperfections that could lead to cracking.

- Loading the kiln: Carefully place your pottery pieces inside the kiln, making sure they are not touching each other or the kiln walls. Leave enough space between each piece to allow for airflow during the firing process.

- Firing schedule: Consult the instructions provided by the manufacturer of your specific kiln for the recommended firing schedule. This will include the temperature and duration for each firing stage: the bisque firing and the glaze firing.

- Bisque firing: The bisque firing is the first firing stage. It helps to remove any remaining moisture and organic materials from the clay, as well as strengthening the pottery. Start the firing process at a low temperature, gradually increasing it until the desired temperature is reached. Maintain this temperature for the specified duration.

- Glazing: After the bisque firing, you can apply glaze to your pottery if desired. Use a brush or dip the pottery in glaze, making sure to eliminate any drips or excess glaze. Allow the glaze to dry completely before proceeding to the next step.

- Glaze firing: The glaze firing is the final firing stage. This process melts the glaze, fusing it to the pottery and giving it a smooth, glass-like finish. Follow the recommended firing schedule for the glaze firing, gradually increasing and maintaining the temperature as specified.

- Cooling: Once the glaze firing is complete, allow the kiln to cool down slowly. Rapid cooling can cause thermal shock and may lead to cracking or breakage of the pottery. Do not open the kiln until it has cooled to room temperature.

By following these steps, you can successfully fire your pottery in the kiln, resulting in beautiful and functional ceramic pieces. It is important to note that firing temperatures and durations may vary depending on the type of clay and glaze you are using, so always refer to the manufacturer’s instructions for best results.

Glazing and Decorating the Pottery

Once your pottery has been fired and is ready to be glazed and decorated, you can start the process of adding color and design to your pieces. Glazing not only adds a protective coating to the pottery, but it also enhances the overall appearance and brings out the colors and textures of the clay.

Here are the steps to glaze and decorate your pottery:

- Prepare your glaze: Start by preparing your glaze according to the manufacturer’s instructions. Glazes come in various colors and finishes, so choose the ones that best suit your design and desired outcome.

- Apply the glaze: Dip your pottery piece into the glaze or use a brush to apply the glaze evenly. Make sure to cover all the surfaces of the pottery with a smooth and even coat of glaze.

- Add decorative elements: If desired, you can add decorative elements to your pottery before or after glazing. This can include painted designs, carved patterns, or even applying decals or transfers. Be creative and experiment with different techniques to achieve your desired look.

- Let the glaze dry: Allow the glaze to dry completely before firing the pottery for the second time. This drying period can take anywhere from a few hours to several days, depending on the type of glaze used and the humidity of the environment.

- Fire the pottery: Once the glaze is dry, place your pottery pieces back in the kiln and fire them at the recommended temperature for the glaze you used. Follow the firing schedule provided by the manufacturer to ensure the glaze properly melts and fuses with the clay body.

After firing, your pottery will have a beautiful glazed finish that showcases your design and craftsmanship. Remember to always follow the safety guidelines when working with glazes and firing pottery to ensure a successful and enjoyable pottery-making experience.

FAQ:

What materials do I need to make handles for pottery?

To make handles for pottery, you will need clay (preferably clay that matches the clay you are using for your pottery), water, a clay knife or scraper, a wooden or metal rib, and a flexible steel wire or cutting tool.

What is the best technique for making handles for pottery?

The best technique for making handles for pottery is to roll out a sausage shape of clay, flatten it slightly, and then attach it to your pot with slip. It’s important to score and slip both the handle and the area on the pot where the handle will be attached to ensure a strong bond.

How do I attach a handle to my pottery?

To attach a handle to your pottery, you will need to score and slip both the handle and the area on the pot where the handle will be attached. Score the surface with a knife or serrated tool, then apply slip (a mixture of clay and water) to both scored surfaces before pressing them together. Smooth out any excess slip and blend the handle into the pot with a rib or your fingers.

Can I make handles for pottery without a pottery wheel?

Yes, you can make handles for pottery without a pottery wheel. The technique for making hand-built handles involves rolling out a sausage shape of clay and then attaching it to your pot using the same scoring, slipping, and smoothing techniques as with wheel-thrown handles. Hand-built handles can add unique character to your pottery.

How can I make decorative handles for pottery?

To make decorative handles for pottery, you can experiment with different shapes and textures. You can add coils, loops, or twists to your handles, or press patterns or textures into the clay. You can also try adding small additions to the handles, such as small clay balls or beads, to create visual interest.