Creating your own pottery kiln can be a rewarding and cost-effective way to pursue your passion for pottery. Whether you’re a beginner or an experienced potter, having your own kiln allows you to have complete control over the firing process and enables you to experiment with different glazes and techniques.

Building a pottery kiln from scratch may seem daunting, but with the right materials and a step-by-step approach, it can be a fun and achievable project. In this guide, we will walk you through the process of building your own pottery kiln, from designing the structure to firing your first batch of pottery.

Step 1: Planning and Design

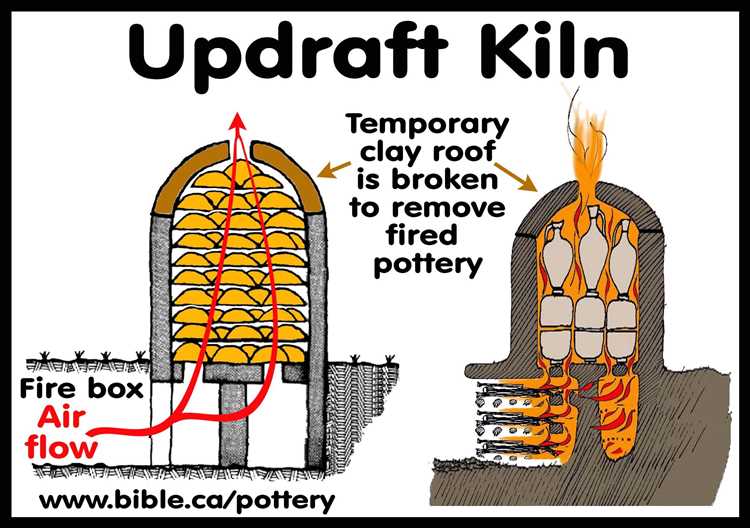

The first step in building your own pottery kiln is to plan and design the structure. Consider the size of the kiln you will need based on the amount of pottery you want to produce and the available space in your studio or backyard. It’s important to ensure that the kiln is well-ventilated and has sufficient insulation to reach and maintain the desired firing temperatures.

Pro tip: Research different kiln designs and consult with experienced potters to determine the best type of kiln for your needs.

Step 2: Gathering Materials

Once you have a plan in place, it’s time to gather the materials you will need to build your kiln. This may include firebricks, insulating bricks, kiln shelves, a kiln lid, burner or heating element, wiring, and a temperature control system. You can purchase these materials from pottery supply stores or search for them online.

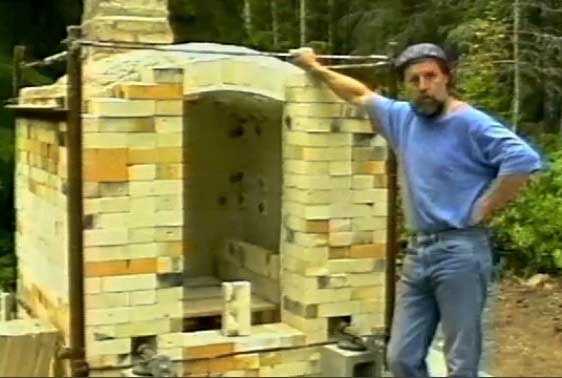

Step 3: Constructing the Kiln

With your materials gathered, you can begin constructing your pottery kiln. Start by laying out the firebricks to form the base and walls of the kiln, using a heat-resistant mortar to secure them in place. Leave openings for the kiln shelves and vent holes. Stack the bricks layer by layer, ensuring that everything is leveled and aligned.

Pro tip: Take your time during this step to ensure the kiln is built solidly and will be able to withstand high temperatures.

Step 4: Installing the Heating Element

Once the kiln structure is complete, it’s time to install the heating element. This could be a gas burner or an electric heating element, depending on your preference and the availability of resources. Follow the manufacturer’s instructions for installing and connecting the heating element, ensuring it is properly positioned inside the kiln.

Gathering Materials

Before you can start building your own pottery kiln, you will need to gather a few materials. Here is a list of what you will need:

- Bricks: You will need a sufficient number of bricks to build the walls of the kiln. Firebricks or refractory bricks are recommended, as they can withstand high temperatures.

- Cement: Cement will be used to hold the bricks together and create a sturdy structure.

- Metal frame: A metal frame will provide the support and stability for the kiln. You can use steel or iron for this purpose.

- Metal mesh: Metal mesh will be used to create a platform for your pottery to sit on. It should be strong enough to support the weight of the pottery.

- Kiln shelves: Kiln shelves are essential for stacking your pottery pieces inside the kiln. You can purchase pre-made kiln shelves or make your own using kiln shelf materials.

- Insulating materials: Insulating materials, such as ceramic fiber or vermiculite, will help to retain heat inside the kiln and improve its efficiency.

- Thermocouple: A thermocouple is a temperature sensor that will allow you to monitor the temperature inside the kiln.

- Propane burner: If you choose to use a propane burner as a heat source, you will need to purchase one that is suitable for your kiln size.

- Safety equipment: It is crucial to have safety equipment, such as heat-resistant gloves, goggles, and a fire extinguisher, to protect yourself while working with the kiln.

Once you have gathered all the necessary materials, you will be ready to move on to the next step of building your own pottery kiln.

Choosing the Right Location

When it comes to building your own pottery kiln, choosing the right location is crucial. Here are some factors to consider:

- Safety: Ensure that the location you choose is safe and meets all safety requirements. Keep in mind that kilns can reach very high temperatures, so it’s important to have a fire-resistant area.

- Ventilation: Adequate ventilation is essential to maintain air quality and remove any potentially harmful fumes. Avoid enclosed spaces without proper ventilation.

- Accessibility: Consider your own convenience and accessibility to the kiln. You’ll need to have easy access to the kiln for loading and unloading pottery.

- Power supply: Make sure the location has a reliable and easily accessible power supply. Kilns require a significant amount of power, so ensure that the electrical system can handle the load.

- Proximity to materials: Consider the proximity of the location to the materials you will need for pottery, such as clay, glazes, and other supplies. It’s more convenient to have them nearby.

Once you have considered these factors, you can choose the best location for your pottery kiln. Don’t forget to check local regulations and obtain any necessary permits before starting the construction process.

Building the Base

Before you can start building your pottery kiln, you’ll need to construct a sturdy base to support the weight of the kiln. Here are the steps to build the base:

- Choose a location: Find a suitable location for your kiln. It should be on a level surface, away from any flammable materials, and in a well-ventilated area.

- Prepare the ground: Clear the area and level the ground where you plan to build the base.

- Gather materials: To build the base, you’ll need bricks, cement, sand, gravel, and rebar. Make sure you have enough of each material for the size of the base you’re building.

- Plan the dimensions: Determine the size of the base based on the dimensions of your kiln. You’ll need to account for the width, length, and height of the kiln, as well as any additional space for ventilation and insulation.

- Excavate the area: Dig a trench around the perimeter of the base, at least a foot deep. This will provide a solid foundation for the bricks.

- Lay the first layer of bricks: Lay a row of bricks in the trench, using cement and sand to secure them in place. Make sure the bricks are level and aligned correctly.

- Add rebar: Place lengths of rebar along the length and width of the base, about every 2 feet. This will provide additional stability and strength.

- Fill with gravel: Fill the trench with gravel, making sure to compact it evenly. This will help with drainage and prevent moisture from building up under the base.

- Continue layering: Continue laying bricks and adding layers of cement and sand until you reach the desired height for the base. Make sure each layer is level and secure.

- Let it cure: Allow the base to cure and dry completely before moving on to the next step. This typically takes a few days.

Once the base is complete, you’ll be ready to move on to building the walls and roof of your pottery kiln.

Constructing the Kiln Walls

Constructing the kiln walls is an important step in building your own pottery kiln. The walls of the kiln need to be sturdy and well-insulated to withstand the high temperatures required for firing pottery.

Here is a step-by-step guide on how to construct the kiln walls:

- Determine the size and shape of the kiln: Before starting the construction, decide on the size and shape of the kiln. This will depend on your specific needs and available space.

- Gather the materials: You will need firebricks, mortar, fireclay, chimney blocks, and insulation materials such as ceramic fiber blanket or ceramic fiber board.

- Prepare the foundation: Start by preparing a solid foundation for your kiln. This can be a concrete slab or a layer of fire bricks.

- Build the base: Lay a row of firebricks on the foundation to create the base of the kiln. Use mortar to secure the bricks in place.

- Construct the walls: Build the walls of the kiln by stacking firebricks on top of the base. Use mortar to secure the bricks together. Leave spaces between the bricks for ventilation.

- Add insulation: Once the walls are constructed, line the inside of the kiln with insulation materials such as ceramic fiber blanket. This will help retain heat and improve the kiln’s efficiency.

- Build the chimney: Install chimney blocks at one end of the kiln to create a ventilation system. The chimney will allow hot air and gases to escape during firing.

- Check for stability: Ensure that the kiln walls are stable and secure. Make any necessary adjustments or reinforcements.

Remember to follow safety precautions and consult professional advice if you are unsure about any aspect of the construction process. Building a kiln requires knowledge of fire safety and heat distribution, so it is important to take the necessary precautions to ensure the safety of yourself and others.

Once the kiln walls are constructed, you will be ready to move on to the next steps of building your own pottery kiln, such as installing burners and controls. With a well-built kiln, you’ll be able to fire your pottery with confidence and achieve the desired results.

Installing the Heating Element

Once you have prepared the structure of your pottery kiln, the next step is to install the heating element. The heating element is responsible for generating the necessary heat inside the kiln to achieve the desired temperature for firing clay.

Follow these steps to install the heating element:

- Choose the heating element: Depending on your budget and preferences, you can opt for either a gas or electric heating element. Gas heating elements are more common and can be more affordable, while electric heating elements are more energy-efficient.

- Measure and cut the heating element: Measure the length of the kiln interior and cut the heating element to match the size. Ensure that the heating element is long enough to cover the entire interior without any gaps.

- Attach the heating element: Secure the heating element to the walls of the kiln using appropriate fixtures and brackets. Make sure that the heating element is well-supported and evenly spaced throughout the interior of the kiln.

- Connect the heating element: If you have chosen an electric heating element, you will need to connect it to a power source. Follow the manufacturer’s instructions or consult a professional electrician to ensure the proper installation and wiring of the heating element.

- Test the heating element: Before using the kiln for firing clay, it is essential to test the heating element. Turn on the kiln and monitor the temperature to ensure that the heating element is functioning correctly and reaching the desired temperature.

By following these steps, you can successfully install the heating element in your homemade pottery kiln. Remember to prioritize safety during the installation process and consult professionals or experts if needed.

Creating the Ventilation System

Proper ventilation is crucial when operating a pottery kiln to ensure the safety and effectiveness of the firing process. Here is a step-by-step guide on creating a ventilation system for your own pottery kiln:

- Determine the location: Choose a well-ventilated area for your kiln, preferably in a separate room or a well-ventilated outdoor space. Ensure that there is enough space around the kiln for the ventilation system to be installed.

- Plan the ventilation system: Decide on the type of ventilation system you want to install. There are two main options to consider:

- Natural ventilation: This involves creating openings in the kiln room to allow for the exchange of air. It is a less complex and costly option but may not provide sufficient ventilation for high-temperature firing.

- Mechanical ventilation: This involves installing a fan or exhaust system to actively remove the hot air and fumes from the kiln room. This option provides better control over the ventilation process but requires more planning and investment.

- Install ventilation openings: If you choose natural ventilation, create openings in the kiln room by installing vents or windows. Ensure that the openings are positioned strategically to allow for the flow of fresh air and the removal of fumes. Consider using adjustable vents to control the airflow.

- Install a fan or exhaust system: If you opt for mechanical ventilation, purchase a suitable fan or exhaust system. Follow the manufacturer’s instructions to install it securely and connect it to an appropriate power source.

- Create a venting system: Depending on the design of your kiln, you may need to install a venting system to channel the hot air and fumes from the kiln to the exhaust or fan. This can be achieved by attaching a vent pipe to the kiln’s vent holes and connecting it to the ventilation system.

- Test the ventilation system: Once the ventilation system is installed, test it before using the kiln for firing. Ensure that the fan or exhaust system is working properly and that the airflow is adequate to remove the heat and fumes generated by the kiln.

Remember to follow all safety guidelines and regulations when setting up your ventilation system. Consult with a professional if you are unsure about any aspect of the installation.

Insulation and Fireproofing

Insulation and fireproofing are essential steps in constructing a pottery kiln. Proper insulation ensures that the heat generated inside the kiln is effectively contained and does not escape, while fireproofing materials protect the kiln structure from damage caused by high temperatures.

Insulation materials:

- Ceramic fiber blanket: This is a common insulation material used in kilns. It is lightweight, easy to install, and has excellent thermal properties.

- Insulating fire bricks: These bricks are made of lightweight materials that have low thermal conductivity. They provide a strong insulation barrier and can withstand high temperatures.

Fireproofing materials:

- Refractory cement: This type of cement is specially formulated to withstand high temperatures. It can be used to seal gaps between bricks and provide additional structural support.

- Refractory mortar: Similar to refractory cement, refractory mortar is used to bond bricks together. It is heat resistant and provides a strong and durable connection.

- Firebricks: These bricks are made of materials that can withstand high temperatures without cracking or breaking. They are used to line the interior of the kiln where the heat is most intense.

- Ceramic fiber board: This board is used to line the kiln walls and provide added insulation. It is lightweight and has excellent thermal properties.

When applying insulation and fireproofing materials, it is important to follow the manufacturer’s instructions and ensure that all surfaces are properly covered. This will help to maximize the kiln’s efficiency and protect it from damage.

Proper insulation and fireproofing:

- Start by lining the kiln walls with a layer of ceramic fiber board. Cut the boards to fit the dimensions of the kiln and secure them in place using refractory mortar.

- Next, apply a layer of ceramic fiber blanket to the interior of the kiln. Cut the blanket to size and secure it using refractory cement.

- For added insulation, line the kiln floor with insulating fire bricks. These bricks can be arranged in a pattern that maximizes heat retention.

- Finally, seal any gaps between bricks and fill in any exposed areas with refractory cement. This will ensure that there are no weak points in the kiln’s structure.

By properly insulating and fireproofing your pottery kiln, you can create a safe and efficient environment for firing your clay creations. Remember to always follow safety guidelines and consult with professionals if needed.

Testing and Safety Precautions

Before using your pottery kiln, it is important to test its functionality and ensure that it is safe to use. Here are some testing and safety precautions to consider:

- Check for any damage: Inspect the kiln thoroughly to make sure there are no cracks, loose wires, or other signs of damage that could pose a safety risk.

- Verify the heating element: Test the heating element to ensure that it is working properly. Turn on the kiln and check if the element heats up evenly and reaches the desired temperature.

- Monitor temperature: Use a separate thermometer to monitor the kiln’s temperature and compare it with the temperature displayed on the kiln’s controller. This will help ensure that the kiln’s temperature is accurate and consistent.

- Check ventilation: Ensure that the kiln is properly ventilated to prevent the buildup of harmful fumes. Make sure there is adequate airflow around the kiln and use a ventilation system if necessary.

- Have a fire extinguisher on hand: In case of emergency, always have a fire extinguisher nearby that is suitable for electrical fires. Familiarize yourself with its usage and keep it in an easily accessible location.

- Wear protective gear: When operating the kiln, always wear protective gear such as heat-resistant gloves, goggles, and an apron to protect yourself from potential burns or injuries.

- Follow manufacturer’s instructions: It is essential to read and follow the manufacturer’s instructions and guidelines provided with the kiln. This will ensure proper usage and minimize safety risks.

By adhering to these testing and safety precautions, you can ensure that your pottery kiln is functioning correctly and that you are working in a safe environment. Remember to prioritize safety at all times when using any type of kiln.

FAQ:

What materials do I need to build a pottery kiln?

To build a pottery kiln, you will need bricks, cement, a metal grate, a thermometer, a propane burner, fire bricks, and a chimney.

Is it difficult to build a pottery kiln?

Building a pottery kiln may require some basic construction skills, but it is not overly difficult. With proper planning and guidance, it can be a feasible DIY project for beginners.

How much does it cost to build a pottery kiln?

The cost of building a pottery kiln can vary depending on the materials and tools you choose to use. On average, it can cost anywhere from $500 to $2000.

Can I use a pottery kiln for other purposes?

While a pottery kiln is primarily designed for firing ceramics and pottery, it can also be used for other purposes such as firing clay sculptures, glass projects, or even metal annealing.

Do I need any special permits or regulations to build a pottery kiln?

The requirements for permits and regulations may vary depending on your location. It is important to consult with your local authorities or building department to ensure you comply with any necessary regulations regarding kiln construction and usage.