Woodworking is a great hobby that allows you to create beautiful and functional furniture pieces from scratch. Whether you’re a beginner or an experienced woodworker, having detailed woodworking plans is essential to successfully complete your projects. In this complete guide, we will walk you through the process of creating woodworking plans, from start to finish.

Creating woodworking plans involves a combination of technical drawing skills and knowledge of woodworking principles. It’s important to have a clear understanding of the final product you want to create and the steps required to achieve it. This guide will teach you how to visualize your project, take accurate measurements, and create detailed drawings that will serve as your roadmap throughout the construction process.

One of the key components of creating woodworking plans is accurately measuring the dimensions of your project. This includes not only the overall measurements but also the specific measurements of individual components and joints. We will show you how to use measuring tools effectively and how to record and organize your measurements to ensure accuracy and precision.

Additionally, we will cover the importance of creating detailed drawings that include all necessary information such as materials, joinery techniques, and assembly instructions. A well-drawn plan will not only guide you through the construction process but will also make it easier to estimate the amount of material needed and anticipate potential challenges or issues that may arise.

By the end of this guide, you will have the knowledge and skills to create your own woodworking plans, allowing you to confidently tackle any woodworking project. Whether you’re planning to build a small table or a complex piece of furniture, having a well-thought-out plan will set you up for success. So, let’s get started and learn how to create woodworking plans like a pro!

Understanding the Basics of Woodworking

Woodworking is a skilled craft that involves working with wood to create a variety of objects, ranging from furniture to decorative items. Before diving into woodworking projects, it is important to understand the basics of this craft.

1. Types of Wood:

- Softwood: Comes from coniferous trees such as pine, fir, and cedar. It is easier to work with but less durable.

- Hardwood: Comes from deciduous trees such as oak, maple, and cherry. It is harder to work with but more durable.

2. Woodworking Tools:

There are various tools used in woodworking, including:

- Saws: Used for cutting wood into desired shapes and sizes.

- Chisels: Used for shaping wood and creating intricate designs.

- Planes: Used for smoothing and shaping wood surfaces.

- Drills: Used for creating holes in wood.

3. Basic Woodworking Techniques:

To work with wood effectively, it is important to know some basic techniques:

- Measuring and Marking: Accurate measuring and marking helps ensure precise cuts and a better end result.

- Cutting: Proper cutting techniques rely on using the correct saw and cutting along the marked lines.

- Sanding: Sanding smoothens rough edges and surfaces for a polished finish.

- Joinery: Joinery techniques involve connecting wood pieces securely using methods such as nails, screws, or dovetail joints.

- Finishing: Applying finishes like paint, varnish, or stain to protect wood and enhance its appearance.

4. Safety Precautions:

Woodworking involves working with sharp tools and machines, so safety precautions are essential:

- Wear protective gear such as safety glasses, gloves, and ear protection.

- Keep work areas clean and organized to avoid accidents.

- Use tools and machines properly, following manufacturer instructions.

- Avoid distractions and stay focused on the task at hand.

5. Learning Resources:

There are many resources available for learning woodworking:

- Books and magazines with woodworking projects and techniques.

- Online tutorials and videos that demonstrate specific woodworking skills.

- Woodworking classes and workshops offered by local community colleges or educational institutes.

By understanding the basics of woodworking, you can embark on woodworking projects confidently and create beautiful pieces of craftsmanship.

Essential Tools and Equipment for Woodworking

Woodworking requires a variety of tools and equipment to complete projects efficiently and effectively. Whether you are a beginner or an experienced woodworker, having the right tools is essential for creating high-quality woodworking plans. Here are some of the essential tools and equipment you will need:

- Measuring Tools: Accurate measurements are crucial in woodworking. Some essential measuring tools include a tape measure, a combination square, a carpenter’s square, and a marking gauge.

- Cutting Tools: Cutting tools are necessary for shaping and cutting wood. Some essential cutting tools include a circular saw, a jigsaw, a table saw, a miter saw, and a hand saw.

- Joinery Tools: Joinery tools are used to connect and secure wood pieces together. Some essential joinery tools include a chisel set, a dovetail jig, a pocket hole jig, and a biscuit joiner.

- Routing Tools: Routing tools are used to create decorative edges and shapes on wood. Some essential routing tools include a router, router bits, and a router table.

- Sanding Tools: Sanding tools are essential for achieving a smooth and polished finish. Some essential sanding tools include a random orbital sander, sandpaper, and sanding blocks.

In addition to these tools, other essential equipment for woodworking includes:

- Workbench: A sturdy workbench is necessary for holding and securing wood pieces during the woodworking process.

- Clamps: Clamps are used to hold wood pieces together firmly while glue dries or when making precise cuts.

- Safety Gear: Safety should always be a priority when woodworking. Essential safety gear includes safety goggles, ear protection, a dust mask, and gloves.

- Finishing Supplies: To add a professional touch to your woodworking projects, you will need finishing supplies such as wood stain, varnish, and brushes.

- Storage and Organization: Woodworking tools require proper storage and organization. Consider investing in a toolbox or a tool cabinet to keep your tools in order.

Remember, investing in high-quality tools and equipment will not only improve the quality of your woodworking projects but also make the process more enjoyable and efficient. Take the time to research and choose the right tools that fit your budget and woodworking needs.

Designing Your Woodworking Plans: Steps to Follow

Designing woodworking plans is an essential step in any woodworking project. It allows you to visualize your project, make precise measurements, and plan out the construction process. Here are the steps to follow when designing your woodworking plans:

- Determine the project dimensions: Start by deciding on the overall size of your project. Consider the available space in your workshop or the intended location for the finished piece. Take accurate measurements and record them.

- Create a rough sketch: Use pencil and paper to create a rough sketch of your project. This will give you a basic visual representation of what you want to build and help you identify any potential design challenges or changes needed.

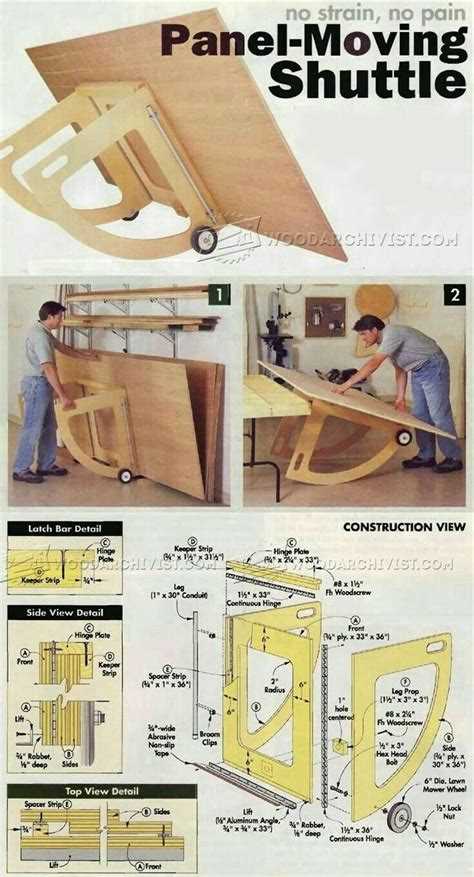

- Make detailed drawings: Once you are satisfied with the rough sketch, create detailed drawings of each component of your project. Include measurements, angles, joinery details, and any other important information. This will serve as a guide during the construction process.

- Consider material and cut lists: Determine the type of wood and other materials you will be using for your project. Create a material list, including quantities needed for each component. Additionally, create a cut list that specifies the dimensions of each piece of wood required.

- Integrate safety measures: As you design your plans, consider incorporating safety measures. This can include adding safety guards, ensuring proper ventilation, and using appropriate personal protective equipment during construction.

- Test your plans: Before starting the actual construction, it is a good idea to test your plans. Verify that the measurements are accurate and that all components fit together as intended. This will help you identify any potential issues and make necessary adjustments.

- Create a step-by-step guide: Once you are confident in your plans, create a step-by-step guide. This guide should provide clear instructions on how to build the project, including assembly order, joinery techniques, and finishing steps.

- Review and revise: Take the time to review your plans and make any necessary revisions before starting the construction. Double-check the measurements, materials, and instructions to ensure accuracy.

By following these steps, you can design woodworking plans that are accurate, detailed, and easy to follow. This will help you stay organized throughout the project and ensure successful results.

Choosing the Right Wood for Your Project

When embarking on a woodworking project, selecting the right type of wood is crucial for the success and durability of your final product. Not all woods are created equal, and each has its own unique characteristics and qualities that make it suitable for specific applications.

1. Softwood vs. Hardwood: The first decision you need to make is whether you want to use softwood or hardwood for your project. Softwood, such as pine or cedar, is generally more affordable and easier to work with, making it a popular choice for beginners or projects that require a lot of cutting and shaping. Hardwood, such as oak or maple, is denser and more durable, making it ideal for furniture or projects that need to withstand heavy use.

2. Appearance: Consider the desired appearance of your final product. Some woods have a natural beauty and unique grain patterns that you may want to showcase. Additionally, certain woods may be more appropriate for staining or painting, depending on the look you want to achieve.

3. Strength and Durability: Assess the strength and durability requirements of your project. If you’re creating something that will be subjected to a lot of wear and tear, like a dining table or outdoor furniture, you’ll want a wood that is known for its strength and resistance to rot and decay.

4. Workability: Take into account how easy or difficult the wood is to work with. Some woods are prone to splitting or warping, while others are more forgiving and easier to shape. Be sure to consider your own skill level and the tools you have available before choosing a wood that may be more challenging to work with.

5. Availability and Cost: Finally, consider the availability and cost of the wood you’re considering. Certain types of wood may be readily available in your area, while others may be more difficult to find or require special ordering. You’ll also want to factor in the price of the wood, as it can vary significantly depending on the type and quality.

By carefully considering these factors and conducting research, you can confidently choose the right wood for your project. Remember, the wood you choose will greatly impact the overall quality, appearance, and longevity of your final product.

Techniques for Joinery and Assembly

Woodworking plans often require the use of various joinery techniques to securely connect pieces of wood together. Here are some common techniques used in woodworking:

- Dovetail joints: These are strong and durable joints that are commonly used in furniture making. They require precision cutting and are often seen in drawers, cabinets, and box construction.

- Mortise and tenon joints: This is a traditional joint that involves one piece of wood having a rectangular hole (mortise) and the other piece having a projection (tenon) that fits into the hole. This joint is commonly found in table legs, chair frames, and door frames.

- Biscuit joints: Biscuit joinery involves using specially shaped oval biscuits that are inserted into slots cut in the wood. This technique is commonly used for aligning and strengthening butt joints.

- Pocket hole joinery: This type of joinery involves drilling a pocket hole at an angle into one piece of wood and using a specialized screw to connect it to another piece. This technique is commonly used in cabinet making and for creating strong joints when screws would otherwise be visible.

- Finger joints: Finger joints, also known as box joints, consist of interlocking rectangular cuts in two pieces of wood that fit together like puzzle pieces. This type of joinery is commonly used in box construction and drawer construction.

Once the joinery is complete, the next step is assembly. The following techniques are commonly used for assembling woodworking projects:

- Clamping: Clamps are crucial for holding pieces of wood together during assembly. They help ensure that the joints are tight and secure.

- Gluing: Wood glue is commonly used to bond pieces of wood together. It is important to apply an even layer of glue and to wipe off any excess to prevent it from interfering with the finish.

- Screwing: Screws are often used in conjunction with joinery techniques for added strength and stability. They are commonly used to secure panels, shelves, and other parts that may need to be disassembled or repositioned.

- Nailing: Nails are commonly used for quick and simple construction. They are often used in combination with glue to provide additional holding power.

- Doweling: Dowels are cylindrical wooden pins that are inserted into pre-drilled holes in two separate pieces of wood to join them together. This technique provides added strength and alignment.

By utilizing these joinery and assembly techniques, you can create sturdy and durable woodworking projects that can withstand the test of time. It’s important to choose the appropriate technique based on the specific requirements of your project and to practice proper technique and precision when executing these methods.

Finishing Touches: Staining and Sealing

Staining and sealing is an important step in the woodworking process as it enhances the beauty of the wood and provides protection against external elements. Here are some tips and guidelines to follow when staining and sealing your woodworking projects:

- Choose the right stain: There are various types of wood stains available, including oil-based, water-based, and gel stains. Consider the type of wood you are working with and the desired finish when selecting a stain. Test the stain on a small, inconspicuous area of the project to ensure you achieve the desired color.

- Prepare the wood: Before applying any stain, it is crucial to prepare the wood surface properly. Sand the wood with progressively finer grit sandpaper to achieve a smooth finish. Remove any dust or debris from the surface using a clean cloth or brush.

- Apply the stain: Use a brush, sponge, or cloth to apply the stain evenly on the wood surface. Work in the direction of the grain to ensure an even application. Let the stain penetrate the wood for the recommended time specified by the manufacturer.

- Remove the excess stain: After the stain has penetrated the wood, use a clean cloth or brush to remove any excess stain. Wipe in the direction of the grain to avoid streaks or uneven coloration.

- Allow the stain to dry: Once you have removed the excess stain, allow the wood to dry completely. Follow the manufacturer’s instructions for drying time, as it may vary depending on the type of stain used.

- Seal the wood: Once the stain is dry, it is essential to seal the wood to protect it from moisture, UV rays, and general wear and tear. There are several options for sealing, including polyurethane, varnish, lacquer, or wax. Apply the chosen sealer using a brush or cloth, ensuring even coverage.

- Reapply if necessary: Depending on the desired level of protection, you may need to apply multiple coats of sealer. Follow the manufacturer’s instructions for drying time between coats, and lightly sand the surface in between coats for optimal adhesion.

- Final touches: Once the final coat of sealer is dry, inspect the wood surface for any imperfections. Lightly sand any rough spots or drips and apply a final layer of sealer if needed. Clean any tools used for staining and sealing properly for future use.

By following these steps and being patient with the staining and sealing process, you can ensure a beautiful and protected finish for your woodworking projects.

Tips and Tricks for Creating Detailed Drawings

Creating detailed drawings for woodworking plans is an essential skill for any woodworker. A well-drawn and understandable plan can make the difference between a successful project and a frustrating experience. Here are some tips and tricks to help you create detailed drawings:

1. Use a scale

When creating woodworking plans, it’s important to use a scale for accurate measurements. Decide on a suitable scale that can fit the entire project on a single page, while still maintaining clarity. Common scales used in woodworking plans are 1/4 inch = 1 foot or 1/2 inch = 1 foot.

2. Include accurate dimensions

Accurate dimensions are crucial in woodworking plans. Measure every component of your project and include the dimensions in your drawings. This will help you avoid any mistakes during construction and ensure that everything fits together correctly.

3. Use descriptive labels

Labeling different parts of your project will make it easier to understand the plan. Use descriptive labels such as “top view,” “side view,” or “front view” to indicate different perspectives. Additionally, label the dimensions of each part so that it’s clear what size each component should be.

4. Add sectional views

In complex projects, adding sectional views can provide a better understanding of how different parts fit together. Sectional views show a cutaway portion of the project to reveal the internal structure. This can be especially helpful for projects with hidden joinery or intricate details.

5. Use shading and hatching

When creating detailed drawings, you can use shading and hatching techniques to indicate different materials or textures. For example, you can use cross-hatching to represent wood grain or shading to highlight areas that are recessed or raised. This will add depth and visual clarity to your drawings.

6. Consider using digital tools

While hand-drawn plans have their charm, using digital tools can make the drawing process faster and more precise. There are many software options available that allow you to create detailed woodworking plans with ease. These tools often include features like automatic dimensioning and 3D modeling, which can be a great asset for creating professional-looking plans.

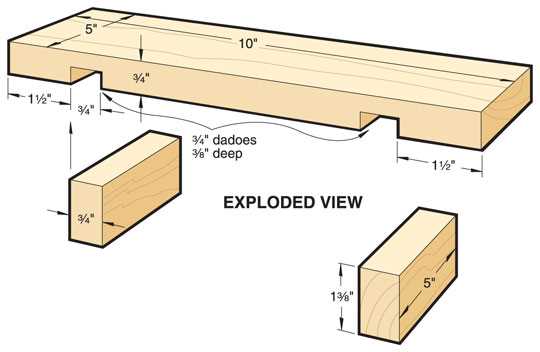

7. Create an exploded view

An exploded view is a drawing that shows how different parts of the project fit together. This can be especially useful for complex projects with multiple components. By showing each part separately and then how they come together, an exploded view can help visualize the step-by-step assembly process.

8. Test your plan

Before finalizing your drawings, it’s a good idea to test your plan by building a prototype or discussing it with other woodworkers. This feedback can help identify any potential issues or improvements that can be made to your plan before starting the actual project.

| Tip | Description |

|---|---|

| Use a scale | Decide on a suitable scale for accurate measurements. |

| Include accurate dimensions | Measure and include the dimensions of each component. |

| Use descriptive labels | Label different parts and dimensions for clarity. |

| Add sectional views | Show cutaway portions to reveal internal structure. |

| Use shading and hatching | Indicate materials or textures for visual clarity. |

| Consider using digital tools | Utilize software options for faster and more precise drawings. |

| Create an exploded view | Show how different parts fit together for easy assembly visualization. |

| Test your plan | Build a prototype or seek feedback before finalizing your drawings. |

Sharing and Selling Your Woodworking Plans

Once you have created your woodworking plans, you may want to share them with others or even sell them to make some money. Here are some ways you can share and sell your plans:

- Online platforms: There are many online platforms and marketplaces where you can share and sell your woodworking plans. Platforms like Etsy, eBay, and Amazon Handmade are popular options for selling digital downloads of your plans.

- Your own website: If you have your own website, you can create a shop section where you can showcase and sell your woodworking plans. This gives you more control over pricing and distribution.

- Social media: You can use social media platforms like Instagram, Facebook, and Pinterest to share and promote your woodworking plans. Create engaging posts, share images and videos of your finished projects, and provide a link to your shop or website.

In addition to sharing and selling your plans digitally, you may also consider offering physical copies of your plans. This can be done by printing and packaging your plans yourself or partnering with a print-on-demand service.

When sharing or selling your woodworking plans, it’s important to consider the following:

- Pricing: Research the market to see what similar plans are selling for and determine a competitive price for your plans. Consider factors like the complexity of the project, the quality of the design, and the demand for similar plans.

- Licensing: Decide whether you want to offer your plans under a specific license. You can choose to offer them for personal use only, for commercial use, or with certain restrictions.

- Promotion: Invest time in promoting your woodworking plans. Use keywords, tags, and descriptions to optimize your listings for search engines. Engage with your audience on social media and provide valuable content related to woodworking.

- Customer support: Be prepared to provide customer support for customers who purchase your plans. Answer questions, provide clarifications, and offer assistance when needed.

Remember to protect your intellectual property by including copyright information on your plans and considering whether you want to implement measures to prevent unauthorized sharing or distribution.

By sharing and selling your woodworking plans, you can not only monetize your passion for woodworking but also inspire and enable others to create beautiful projects of their own.

FAQ:

What is woodworking?

Woodworking is the skill or activity of making items from wood, including furniture, cabinetry, and other decorative pieces.

Why is creating woodworking plans important?

Creating woodworking plans is important because it helps woodworkers visualize and organize their projects, ensuring accurate measurements and efficient use of materials. It also serves as a reference guide during the construction process.

What are the key components of woodworking plans?

The key components of woodworking plans include a detailed list of materials, accurate measurements, step-by-step instructions, and diagrams or illustrations to guide the construction process.

How can I start creating woodworking plans?

To start creating woodworking plans, you should first have a clear understanding of the project you want to build. Sketch out your ideas and make a list of materials and measurements. Break the project down into steps and create detailed instructions for each step. You can also use software or online tools to assist in creating professional-looking plans.

Are there any specific tools or software I can use to create woodworking plans?

Yes, there are several tools and software options available for creating woodworking plans. Some popular options include SketchUp, AutoCAD, and Fusion 360. These programs allow you to create 3D models, generate accurate measurements, and create professional-looking diagrams and illustrations.

What are some tips for creating accurate and useful woodworking plans?

Some tips for creating accurate and useful woodworking plans include taking precise measurements, double-checking all calculations, including clear and detailed instructions, and using proper labeling and symbols in your diagrams. It’s also helpful to gather feedback from other experienced woodworkers to ensure the plans are easy to understand and follow.

Can I sell the woodworking plans I create?

Yes, you can sell the woodworking plans you create, provided you have the necessary rights and permissions for any copyrighted designs or materials used. Many woodworkers sell their plans online through their websites, marketplaces, or woodworking communities.