Woodworking is an ancient craft that allows us to create beautiful and functional objects from one of nature’s most versatile materials. While there are many techniques and tools available to shape wood, one of the most fascinating and satisfying methods is steam bending. By using the power of steam and heat, woodworkers can create elegant curves and arches that would be impossible to achieve with traditional woodworking techniques.

Steam bending works by softening the wood fibers through the application of steam, allowing them to be bent into shape without breaking or cracking. This technique has been used for centuries and is still widely used today in the creation of furniture, musical instruments, and decorative items. Not only does steam bending allow for unique and visually striking designs, but it also enhances the strength and stability of the wood, making it a popular choice among craftsmen.

To begin the steam bending process, the wood is first carefully selected for its moisture content and structural integrity. It is then heated in a steam box, which is essentially a sealed chamber filled with steam. The steam penetrates the wood, making it pliable and easy to bend. Once the wood has reached the desired temperature and moisture content, it is quickly removed from the steam box and bent into shape using specialized jigs and clamps.

It is important to note that steam bending requires skill and experience to achieve the desired results. Factors such as wood species, thickness, and the duration of the steam exposure all play a role in the success of the bending process. Additionally, safety precautions must be taken when working with steam and hot wood to minimize the risk of burns or accidents.

Whether you are a seasoned woodworker or just starting out, steam bending is a technique that can add a new dimension to your projects. It offers endless possibilities for creative design and allows you to push the boundaries of what can be accomplished with wood. So, if you are ready to take your woodworking to the next level, why not give steam bending a try?

What is steam bending?

Steam bending is a technique used in woodworking to shape wood into curved or arched forms. It involves exposing the wood to steam in order to make it more flexible and pliable. This allows the wood to be bent into a desired shape without breaking or cracking.

The process of steam bending involves the use of a steam box, which is a container that is filled with steam. The wood that needs to be bent is placed inside the steam box and exposed to the steam for a set period of time. The duration of time needed will vary depending on the type and thickness of the wood being used.

While the wood is inside the steam box, the heat and moisture from the steam will soften the lignin, which is the natural glue that holds the wood fibers together. This softens the wood and makes it more malleable, allowing it to be bent without the risk of breaking.

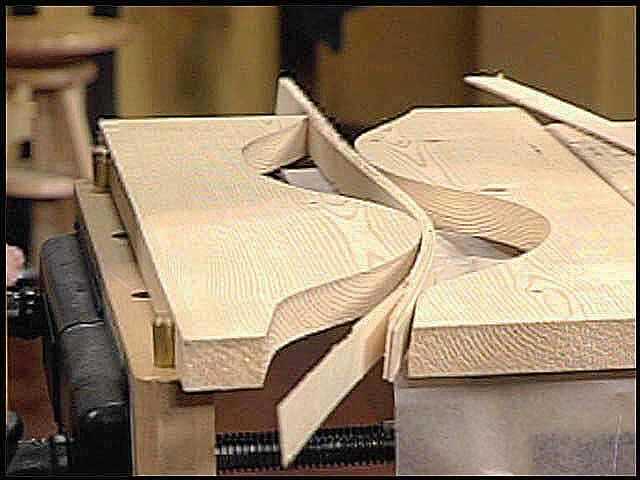

After the wood has been steamed for the appropriate amount of time, it is quickly removed from the steam box and placed onto a bending form or jig. The wood is then clamped or secured into the desired shape and left to cool and dry. As the wood cools, it will harden and retain the shape it was bent into.

Steam bending is a popular technique used by woodworkers to create a wide range of curved and arched forms, such as chair backs, guitar necks, and boat frames. It is a versatile and effective method for shaping wood and can produce unique and visually stunning results.

Benefits of steam bending wood

Steam bending wood is a traditional woodworking technique that offers several benefits. Here are some of the reasons why you should consider using steam bending in your projects:

- Flexibility: Steam bending allows you to create curves and arches that are difficult or impossible to achieve with other woodworking techniques. This flexibility opens up a wide range of design possibilities and allows you to create unique and artistic pieces.

- Strength: Steam bending wood can actually increase the strength of the wood. The steam softens the lignin, which is the natural glue that holds the wood fibers together. This makes it easier for the wood to bend without breaking, resulting in a stronger and more durable final product.

- Cost-effectiveness: Steam bending can be a cost-effective solution for creating curved and arched pieces. Compared to other methods like laminating multiple thin layers of wood or using expensive machinery, steam bending requires minimal equipment and materials.

- Environmentally friendly: Steam bending is a sustainable and eco-friendly technique. It does not require the use of harsh chemicals or adhesives, reducing the impact on the environment. Additionally, steam bending allows you to make the most out of each piece of wood, reducing waste.

- Historical significance: Steam bending has been used by craftsmen for centuries and has a rich history. By using this technique, you can connect with traditional woodworking methods and preserve a centuries-old craft.

In conclusion, steam bending wood offers a range of benefits, from increased design flexibility and strength to cost-effectiveness and sustainability. By incorporating steam bending into your woodworking projects, you can achieve unique and visually appealing curved and arched pieces.

How to prepare wood for steam bending

Steam bending wood is a technique used to create curves and arches in wooden projects. To successfully steam bend wood, it is essential to properly prepare the wood to make it more pliable and easy to shape. Follow these steps to prepare wood for steam bending:

-

Select the right wood: Not all types of wood are suitable for steam bending. Hardwoods like oak, walnut, and ash are more commonly used because they have higher strength and flexibility. Avoid using softwoods like pine or spruce as they may crack or break during the bending process.

-

Prepare the wood: Start by cutting the wood into long, thin strips or planks. The thickness of the pieces will depend on how tight of a curve you want to achieve. Thinner pieces are more flexible but may be more prone to cracking, so consider the project requirements when selecting the wood thickness.

-

Steam the wood: Steam bending requires heating the wood to make it more pliable. You can do this by using a steam box or a steam chamber. The steam box should be large enough to fit the wood pieces comfortably. The wood needs to be steamed for a specific period of time to soften it properly. The exact time will depend on the type and thickness of the wood.

-

Soak the wood: After steaming, immediately transfer the wood to a container filled with cold water. This sudden temperature change will set the wood’s new shape and help it retain the curved form.

-

Shape the wood: Once soaked, carefully bend the wood into the desired shape. Use clamps or jigs to hold the wood in place until it dries completely. Allow the wood to dry naturally, as forcing it to dry faster can lead to cracks or deformities.

-

Finishing touches: After the wood has dried and retained its shape, you can remove any excess moisture by sanding it. Apply a wood sealer or finish to protect the wood and enhance its appearance if desired.

By following these steps, you can prepare wood for steam bending and achieve beautiful curves and arches in your woodworking projects.

Selecting the right type of wood

When it comes to steam bending wood, selecting the right type of wood is crucial for a successful outcome. Not all types of wood are suitable for steam bending, as some woods have a higher propensity for splitting or breaking under pressure.

Here are some factors to consider when selecting the wood for steam bending:

- Bendability: Not all woods can be easily bent using steam. Certain types of wood, such as oak, ash, maple, and cherry, are known for their bendability and are commonly used for steam bending projects. These woods have long fibers that allow them to withstand the bending process without breaking.

- Moisture content: Wood needs to have a certain moisture content in order to be successfully steam bent. Wood with a moisture content of around 20% is ideal for steam bending. Wood that is too dry may crack or break during the bending process, while wood that is too wet may develop deformities or fail to retain its shape.

- Straightness: Wood that has straight grain patterns is more suitable for steam bending compared to wood with irregular or twisted grains. Straight-grained wood is less likely to deform or break under pressure and is easier to work with.

- Thickness: Thinner pieces of wood are generally easier to bend with steam compared to thicker pieces. Thicker pieces of wood may require longer steaming times and higher pressure to achieve the desired bend, increasing the risk of cracking or breaking.

- Availability: Consider the availability of the wood species you have chosen for your steam bending project. Some rare or exotic woods may be more difficult to source, which could affect the feasibility and cost of your project.

It is important to note that even with the right type of wood, steam bending requires practice and skill. It is recommended to start with simpler projects and gradually progress to more complex bends as you gain experience and confidence in your steam bending abilities.

Properly prepping the wood

Before you start steam bending wood, it is crucial to properly prepare the wood for the bending process. Here are some steps you should follow:

- Select the right type of wood: Not all types of wood are suitable for steam bending. Look for woods with low elasticity and high flexibility, such as ash, oak, or hickory.

- Choose the right thickness: For best results, the wood should be around 1/8 to 1/4 inches thick. Thicker wood may require longer steaming times and greater pressure to bend.

- Prepare the wood: Remove any knots, imperfections, or excessive moisture from the wood. Smooth the surface and ensure it is free from any debris or dirt that could interfere with the bending process.

- Moisturize the wood: Before steaming, it’s important to moisturize the wood to prevent it from drying out. You can do this by sealing the ends of the wood with wax or applying a layer of water-based sealant. This will help the wood to maintain its moisture content during the steaming process.

- Apply steam-resistant tape: To protect the wood during steaming, wrap it with steam-resistant tape. This tape will help to prevent the wood from splitting or cracking due to the high temperatures and moisture.

By properly prepping the wood, you’ll ensure that it’s in the best condition for steam bending. This will increase the chances of achieving the desired curves and arches in your projects.

Steam bending techniques

Steam bending is a popular technique used in woodworking to create curved shapes and arches in wood. It involves exposing the wood to steam heat to make it pliable enough to bend and shape. This article explores some steam bending techniques that can help you achieve beautiful curves in your woodworking projects.

1. Selecting the right wood

Not all woods are suitable for steam bending. It’s important to choose a wood species that has good bending properties and can withstand the steam and heat. Some popular choices for steam bending include ash, oak, hickory, and walnut.

2. Preparing the wood

Before steam bending, the wood needs to be properly prepared. This involves soaking the wood in water for a certain period of time to increase its moisture content. The moisture in the wood helps to make it more pliable and reduces the risk of cracking or splitting during the bending process.

3. Building a steam box

A steam box is essential for the steam bending process. It is a closed container that holds the wood and steam, allowing the wood to soften and become flexible. The steam box should be made from a heat-resistant material such as PVC pipe or metal and should be large enough to accommodate the length and width of the wood being bent.

4. Steam bending process

Once the steam box is prepared, the wood can be inserted and heated using a steam generator or other heat source. The wood should be left in the steam box for a sufficient amount of time to become pliable. The exact time will depend on the thickness and moisture content of the wood. Typically, it can take anywhere from 30 minutes to several hours.

After the wood has been steamed, it should be removed from the steam box and immediately shaped into the desired curve or arch. This is usually done using clamps or a bending form to hold the wood in place until it cools and holds its shape. It’s important to work quickly and efficiently during this step to ensure the wood retains its flexibility for shaping.

5. Drying and finishing

After the wood has been bent, it needs to be dried and stabilized to prevent it from losing its shape. This can be done by air drying or using a kiln. Once the wood is dry, it can be sanded and finished as desired to complete the project.

Conclusion

Steam bending is a fascinating technique that can unlock a world of design possibilities in woodworking. By selecting the right wood, properly preparing it, building a steam box, and following the steam bending process, you can create beautiful curves and arches in your projects. Remember to take safety precautions when working with steam and always follow proper techniques to ensure successful results.

Using a steam box

A steam box is a crucial tool when it comes to steam bending wood. It is a relatively simple setup but requires attention to detail to ensure the wood is properly heated and shaped.

Here are the steps to effectively use a steam box for steam bending wood:

- Choose the right wood: Not all types of wood are suitable for steam bending. Softer woods like oak, ash, and walnut are commonly used. It is important to select wood with straight grain and minimal knots or defects.

- Create the steam box: The steam box can be made from plywood or any other type of material that can withstand high heat and moisture. It should be large enough to accommodate the length and thickness of the wood you are bending.

- Prepare the wood: Prior to steam bending, the wood should be soaked in warm water for at least a couple of hours. This helps to make the wood more pliable and reduces the risk of cracking during the bending process.

- Place the wood in the steam box: Once the wood has been soaked, it should be placed inside the steam box. Make sure the wood is positioned in a way that allows steam to circulate evenly around the entire piece.

- Steam the wood: The steam box should be connected to a steam source such as a steam generator or a kettle. The wood should be steamed for an adequate amount of time based on its thickness. As a general rule, one hour of steaming per inch of wood thickness is recommended.

- Remove the wood from the steam box: After the steaming process is complete, the wood should be carefully removed from the steam box using heat-resistant gloves or tongs. Be cautious as the wood will be hot and flexible.

- Bend the wood: Once the wood is out of the steam box, it should be quickly but gently bent into the desired shape. It is important to work efficiently before the wood starts to cool down and lose its pliability.

- Secure the wood: After bending, the wood should be clamped or secured in its curved position until it cools and dries. This step helps to maintain the shape and prevent the wood from springing back.

- Allow the wood to dry: Give the wood sufficient time to dry and set in its curved shape. This may take a few days to a few weeks, depending on the type of wood and its thickness.

- Finish the wood: Once the wood is completely dry, it can be sanded, stained, or finished according to your preference. This step adds the final touch to your steam bent wood project.

By following these steps and using a steam box properly, you can achieve beautiful curves and arches in your woodworking projects.

Applying steam to the wood

Steam bending is a technique that involves the use of heat and moisture to make wood pliable enough to bend and shape into desired curves and arches. Steam bending allows for greater flexibility and creativity in woodworking projects, as it opens up possibilities for unique designs and structures that may not be achievable with traditional cutting and shaping methods.

The process of steam bending wood involves subjecting the wood to high temperatures and steam, which softens the lignin and cellulose fibers in the timber. This combination of heat and moisture makes the wood more pliable and allows it to be bent and shaped without breaking or cracking.

To apply steam to the wood, a steam box or chamber is typically used. This is a special enclosure that is designed to generate and hold steam, allowing the wood to be exposed to the moisture and heat for an extended period of time. The steam box can be made from various materials, such as wood, metal, or plastic, as long as it is able to retain the steam and withstand the high temperatures.

The wood to be steam bent is placed inside the steam box and sealed to ensure that the steam doesn’t escape. One end of the steam box is connected to a steam generator, which produces the steam that is pumped into the box. The steam generator can be as simple as a pot of boiling water with a hose attached, or it can be a more complex system specifically designed for steam bending.

The length of time that the wood needs to be exposed to steam depends on several factors, including the thickness and type of wood, as well as the desired degree of bend. Generally, thinner and softer woods require less time, while thicker and hardwoods may need to be steamed for longer periods. It’s important to closely monitor the wood during the steaming process to ensure that it reaches the desired flexibility without becoming overcooked or damaged.

Once the wood has been sufficiently steamed, it is carefully removed from the steam box and immediately bent into the desired shape or placed in a bending form to maintain the curved shape as it cools and dries. The wood should be carefully handled during the bending process to avoid any sudden or excessive pressure that could cause it to crack or break.

After the wood has been successfully bent and shaped, it is typically allowed to dry for a period of time to regain its strength and stability. This drying process helps to set the wood in its new shape and prevent any potential warping or deformation. The time required for drying varies depending on the type of wood, thickness, and climate conditions.

In conclusion, applying steam to wood is a critical step in the process of steam bending. By subjecting the wood to heat and moisture, it becomes more pliable and can be bent into desired curves and arches. The use of a steam box or chamber, along with a steam generator, allows for controlled and precise application of steam to the wood. However, it’s important to carefully monitor the steaming process to prevent overcooking or damaging the wood.

Shaping curves and arches

When working with wood, there are various techniques you can use to shape curves and arches. One popular method is steam bending, which allows you to bend wood to your desired shape using heat and moisture. Here are some steps to help you achieve beautiful curved and arched pieces for your project:

- Choose the right wood: Not all types of wood are suitable for steam bending. It is important to select a wood species that has the right flexibility and strength for bending without breaking. Some common choices include ash, oak, and maple.

- Prepare the wood: Before bending, you need to prepare the wood by removing any knots or other imperfections. It is also recommended to steam the wood beforehand to make it more pliable.

- Create a bending form: A bending form is a custom-made mold that will help you achieve the desired shape. It should be made from a strong and heat-resistant material such as metal or plywood. The form should be designed to match the curve or arch you want to achieve.

- Apply steam: Steam is a crucial component of steam bending. It softens the wood fibers and makes the wood pliable. You can use a steam box or a steam generator to create the necessary steam. The wood needs to be exposed to steam for a certain amount of time depending on its thickness.

- Bend the wood: Once the wood is properly steamed, carefully remove it from the steam source and quickly transfer it to the bending form. Use clamps or straps to hold the wood in place and press it against the form. Apply pressure gradually to avoid cracking or breaking.

- Allow the wood to dry and set: After bending, the wood needs time to dry and set in the new shape. It is essential to let it cool and dry completely before removing it from the form. This will help the wood retain its shape and prevent it from springing back.

With practice and the right technique, you can master the art of shaping curves and arches with steam bending. It is a versatile method that can be used for various woodworking projects, from furniture to musical instruments. Experiment with different wood species and shapes to create unique and beautiful curved pieces for your next project.

Using forms and clamps

When steam bending wood, it’s important to have a proper form or mold to shape the wood into the desired curve or arch. The form should be made of a material that can withstand high temperatures and moisture, such as metal or plywood.

Before bending the wood, it’s important to prepare the form by applying a release agent, such as wax or oil, to prevent the wood from sticking to the form. This will make it easier to remove the wood once it has been bent.

Once the form is prepared, the wood should be soaked in water for a certain period of time to make it more pliable and easier to bend. The length of time required for soaking will depend on the type and thickness of the wood being used.

After soaking, the wood should be clamped onto the form using clamps or straps. The clamps should be tightened evenly to ensure that the wood is held securely in place and that the pressure is distributed evenly along the length of the wood.

Once the wood is clamped onto the form, it’s time to apply steam. A steam generator or a steaming box can be used to produce the necessary steam. The wood should be placed in the steam chamber and exposed to the steam for a certain period of time, again depending on the type and thickness of the wood.

The steam will soften the wood fibers, making it more pliable and easier to bend. Once the wood has been steamed, it should be quickly removed from the steam chamber and placed onto the form.

While the wood is still hot and pliable, it should be bent into the desired shape. This can be done by pressing down on the wood or using additional clamps or straps to hold it in place. It’s important to work quickly and efficiently, as the wood will start to cool and harden once it is removed from the steam.

Once the wood has cooled and hardened, it can be removed from the form and any excess moisture can be dried off. The wood should be left to dry and cure for a certain period of time, usually several days or weeks, depending on the type and thickness of the wood.

After the wood has fully cured, it can be sanded, finished, and incorporated into your woodworking project. The final result will be a beautifully curved or arched piece of wood that adds a unique and artistic touch to your project.

FAQ:

What is steam bending wood?

Steam bending wood is a technique used to shape the wood by exposing it to steam and then bending it into different curves and arches.

What types of wood can be steam bent?

A wide variety of wood types can be steam bent, including oak, ash, walnut, cherry, and maple.

How does the process of steam bending wood work?

The wood is first soaked in water and then placed in a steam box or steam chamber, where it is exposed to high-pressure steam. This softens the wood fibers, making them more pliable. Once the wood is flexible enough, it is carefully bent into the desired shape and held in place until it sets and dries.

What are some common applications of steam bending wood?

Steam bending wood is commonly used in furniture making, particularly for chair backs, arms, and legs. It is also used in the creation of decorative arches and curved handrails.

Are there any limitations to steam bending wood?

Yes, there are some limitations to steam bending wood. It may not be suitable for certain species of wood that are prone to splitting or have a high tendency to spring back to their original shape. Additionally, the size and thickness of the wood may also restrict the degree of curvature that can be achieved.