When it comes to woodworking, one of the most important factors to consider is the moisture content of the wood. Whether you’re building furniture, crafting cabinets, or creating beautiful wooden artworks, understanding and controlling the moisture content is crucial for the success and longevity of your project.

The moisture content of wood refers to the amount of water present in the wood fibers. Wood with high moisture content is prone to shrinking, warping, and cracking, while wood with low moisture content can become brittle and difficult to work with. Achieving the right moisture content ensures that the wood is stable and that the finished product will withstand the test of time.

There are several methods for measuring the moisture content of wood, including using a moisture meter, weighing the wood before and after drying, or using a testing kit. Once you have determined the moisture content, you can take steps to either reduce or increase it, depending on the desired outcome for your project.

In general, most woodworking projects require wood with a moisture content between 6% and 8%. This range provides a balance between stability, workability, and the natural movement of the wood. However, certain projects may require different moisture content levels, such as outdoor furniture or musical instruments.

In this complete guide, we will explore the importance of moisture content in woodworking, the different methods for measuring it, and the steps you can take to achieve the right moisture content for your specific project. Whether you’re a beginner or an experienced woodworker, understanding and controlling moisture content will improve the quality and durability of your woodworking projects.

Understanding Moisture Content

Moisture content is a critical factor to consider when working with wood in any woodworking project. It refers to the amount of water present in the wood, typically expressed as a percentage of the wood’s weight. Understanding moisture content is important because it affects the stability and durability of wood and can impact the success of your woodworking projects.

Here are some key points to help you understand moisture content:

- Natural Moisture Content: Wood naturally contains water, which is present in the form of moisture. The amount of moisture in freshly cut or live trees is known as the natural moisture content. It can vary depending on the species of wood and the environmental conditions in which the tree grew.

- Equilibrium Moisture Content (EMC): When wood is exposed to its surrounding environment, it tends to adjust its moisture content to match the humidity in the air. This state is known as equilibrium moisture content (EMC). The equilibrium moisture content is influenced by factors such as temperature, relative humidity, and the type of wood.

- Wood Movement: As wood absorbs or releases moisture from the environment, it undergoes dimensional changes. This movement can cause wood to expand or contract, which can lead to warping, splitting, or cracking. Understanding the moisture content of the wood is crucial to prevent these issues and ensure the stability of your woodworking projects.

- Moisture Meters: Moisture meters are devices that measure the moisture content of wood. They work by either using electrical resistance or electromagnetic waves to determine the moisture level. Moisture meters are essential tools for woodworkers to accurately assess the moisture content of wood before using it in their projects.

- Target Moisture Content: Different woodworking projects require different moisture content levels. For example, furniture making typically requires wood with a moisture content of around 6% to 8%, while exterior construction may necessitate wood with lower moisture content to withstand weathering. It is essential to know the target moisture content for your specific project and ensure the wood reaches that level before use.

By understanding moisture content and its implications, woodworkers can make informed decisions about selecting, storing, and using wood in their projects. It is a crucial factor to consider to ensure the quality and longevity of your woodworking creations.

The Importance of Moisture Content in Woodworking

In woodworking, moisture content is a critical factor that affects the overall quality and stability of the finished product. It refers to the amount of water present in the wood, expressed as a percentage of the wood’s weight. Having the appropriate moisture content is essential for ensuring the strength, durability, and aesthetics of the wooden items.

1. Dimensional Stability: One of the key reasons why moisture content is crucial is because it directly affects the dimensional stability of the wood. Wood has a natural tendency to expand and contract as its moisture content fluctuates. Therefore, using wood with improper moisture content can lead to warping, twisting, and splitting of the finished product. By properly drying or conditioning the wood, woodworkers can minimize these issues and create stable, long-lasting pieces.

2. Strength and Durability: The moisture content of wood also plays a significant role in determining its strength and durability. When wood is excessively wet, it tends to be softer and weaker, making it more prone to damage and decay. On the other hand, if the wood is too dry, it can become brittle and easily crack. By choosing wood with the appropriate moisture content, woodworkers can ensure that their projects are strong and durable.

3. Workability: Achieving the right moisture content in wood is crucial for making it easier to work with. Wood that is too wet can be challenging to shape, cut, and join, as it may have a higher density and be prone to tearing and splintering. Conversely, overly dry wood can be difficult to saw, plane, or carve, as it may be too hard or rigid. By carefully drying and acclimating the wood to the appropriate moisture content, woodworkers can improve its workability and achieve better results.

4. Finishing and Appearance: Moisture content also affects the final appearance and finishing of wood projects. Excess moisture in the wood can hinder the adhesion and absorption of stains, paints, or finishes, leading to uneven coloration or poor surface quality. In contrast, wood that is too dry may absorb finishes too quickly, resulting in a blotchy or uneven appearance. By properly managing the moisture content, woodworkers can achieve a smooth, attractive finish on their projects.

In conclusion, moisture content should be carefully considered in all woodworking projects. It directly affects the dimensional stability, strength, workability, and finishing of wood. By understanding and managing the moisture content, woodworkers can enhance the quality and longevity of their creations.

How Moisture Content Affects Wood

Moisture content is a crucial factor that affects the behavior, appearance, and stability of wood in woodworking projects. The moisture content of wood refers to the amount of water present in the wood fibers.

Dimensional Changes:

Wood is a hygroscopic material, meaning that it absorbs and loses moisture in response to changes in relative humidity. As wood absorbs moisture, it expands, and as it loses moisture, it contracts. This dimensional change can lead to warping, cupping, splitting, and other forms of deformation in woodworking projects.

Strength and Stability:

The moisture content of wood also affects its strength and stability. When wood is at its optimal moisture content, it is both strong and stable. However, if the moisture content is too high, the wood becomes weak and prone to damage. On the other hand, if the moisture content is too low, the wood can become brittle and prone to cracking.

Workability:

The moisture content of wood also affects its workability. When wood is too wet, it can be difficult to work with as it tends to be softer and more prone to tearing and splintering. Conversely, when wood is too dry, it can be challenging to cut and shape as it becomes harder and more brittle.

Finishing and Appearance:

The moisture content of wood also affects the finishing and appearance of woodworking projects. When wood has a high moisture content, it can prevent finishes, such as paint or stain, from adhering properly. Additionally, wood with a high moisture content tends to have a lighter color compared to wood with a lower moisture content.

Storage and Longevity:

Proper moisture content is essential for the storage and longevity of wood products. Wood with a high moisture content is more susceptible to decay, mold, and insect infestation. Controlling and maintaining the moisture content of wood can help prevent these issues and extend the lifespan of woodworking projects.

Overall, understanding how moisture content affects wood is crucial for ensuring the success and durability of woodworking projects. Controlling and maintaining the appropriate moisture content for your woodworking materials is essential for achieving the desired results and avoiding potential problems.

Dimensional Stability and Moisture Content

Moisture content is a critical factor that affects the dimensional stability of wood in woodworking projects. When wood absorbs or loses moisture, it expands or contracts accordingly, leading to changes in its dimensions. Understanding the relationship between moisture content and dimensional stability is essential for achieving well-crafted and durable woodworking projects.

Effect of Moisture Content on Dimensional Stability

Wood is a hygroscopic material, meaning it readily absorbs or releases moisture from the surrounding environment. The amount of moisture content in wood is usually expressed as a percentage based on the weight of the wood relative to its dry weight. As the moisture content of wood changes, so does its dimensions.

When wood absorbs moisture from a humid environment, it swells or expands. Conversely, when wood loses moisture in a dry environment, it shrinks or contracts. This expansion and contraction can lead to warping, cupping, splitting, and other dimensional changes in the wood.

Impact on Woodworking Projects

Choosing and working with wood at the appropriate moisture content is crucial for ensuring the long-term stability and quality of woodworking projects. If wood with a high moisture content is used in a project, it will likely shrink as it dries, potentially causing joints to pull apart and compromising the structural integrity of the piece.

On the other hand, if wood with a low moisture content is used, it may later absorb moisture from the surrounding environment, causing it to expand and potentially damage the project. This is particularly important for projects that will be exposed to varying moisture levels, such as outdoor furniture.

Controlling Moisture Content

Woodworkers have several methods for controlling the moisture content of wood. One common approach is air drying, where freshly cut wood is stacked in a well-ventilated area and allowed to naturally dry over an extended period. Kiln drying is another method, which involves placing wood in a special chamber where temperature and humidity are controlled to speed up the drying process.

Woodworkers can also use moisture meters to measure the moisture content of wood before using it in a project. This allows them to determine whether the wood is at an appropriate moisture level for their specific project.

Conclusion

Dimensional stability is closely tied to the moisture content of wood in woodworking projects. By understanding how moisture content affects the dimensions of wood and taking appropriate steps to control and manage it, woodworkers can ensure they create durable, stable, and high-quality pieces that will stand the test of time.

Strength and Moisture Content

The moisture content of wood has a significant impact on its strength and dimensional stability. Wood is an organic material that naturally absorbs and releases moisture from the environment. As moisture levels change, wood expands and contracts, which can affect its strength and performance.

When wood is harvested and initially processed, it contains a high level of moisture. This moisture is known as “green” or “fresh” moisture, and it needs to be removed before the wood can be used for woodworking purposes. Green wood is generally weak and prone to warping, splitting, and shrinking as it dries.

As the moisture content of wood decreases, its strength increases. Moisture content is typically measured as a percentage of the oven-dry weight of the wood. The higher the moisture content, the weaker the wood will be. Therefore, it is crucial to dry wood to the appropriate moisture content for the intended use.

Wood becomes significantly stronger and more stable as the moisture content drops below a certain level. For most interior woodworking projects, wood with a moisture content between 6% and 8% is considered ideal. This moisture content provides a balance between dimensional stability and workability. Wood with a moisture content below 6% may become brittle and prone to cracking, while wood with a moisture content above 8% may still be prone to warping and shrinking.

It’s important to note that the ideal moisture content for woodworking can vary depending on the specific project and environmental conditions. In some cases, such as outdoor furniture or marine applications, wood with a higher moisture content may be preferred to ensure it can withstand the elements.

Additionally, different wood species have different moisture content requirements. Some species, such as oak or hickory, may require a slightly higher moisture content for optimal performance, while others, like maple or birch, may perform better with a lower moisture content.

Ultimately, achieving the right moisture content for woodworking involves careful drying and conditioning of the wood. This process helps to create stronger, more stable wood that is less prone to cracking, warping, and other forms of damage.

Measuring Moisture Content in Wood

Accurately measuring the moisture content in wood is an essential step in woodworking projects. Moisture content affects the stability and durability of the wood, and it is important to ensure that the wood is at the appropriate moisture level for a specific project. Here are some common methods for measuring moisture content:

- Moisture meters: Moisture meters are widely used tools in woodworking. They provide a quick and convenient way to measure the moisture content of wood. There are two types of moisture meters: pin-type and pinless. Pin-type meters use two sharp pins inserted into the wood, providing a direct measurement of moisture content. Pinless meters use electromagnetic waves to measure the moisture content without leaving any marks on the wood surface. Both types provide accurate readings and are suitable for different woodworking applications.

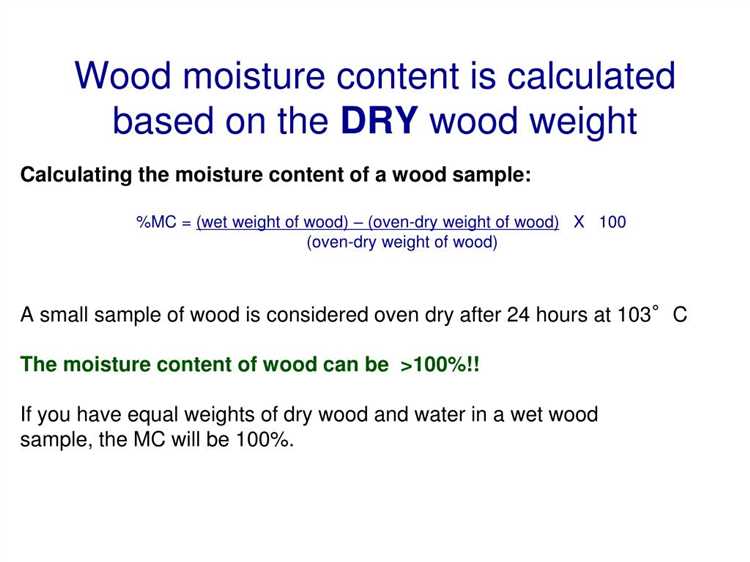

- Oven-drying method: The oven-drying method is a traditional technique for measuring moisture content in wood. It involves weighing a small sample of wood, drying it in an oven at a specific temperature, and then reweighing it. The difference in weight before and after drying is used to calculate the moisture content. This method is accurate but time-consuming and may not be suitable for larger woodworking projects.

- Resistance meters: Resistance meters, also known as electrical resistance moisture meters, measure moisture content by passing an electrical current through the wood and measuring the electrical resistance. Moisture affects the electrical conductivity of wood, and the meter converts the resistance into a moisture content value. These meters are easy to use and provide quick readings, but they may not be as accurate as other methods.

Regardless of the method chosen, it is important to ensure that the moisture content is within an acceptable range for the specific project. Wood with a moisture content that is too high or too low can warp, crack, or decay over time. Properly measuring and controlling moisture content is crucial for achieving the best results in woodworking.

Moisture Meters for Woodworking

Moisture meters are essential tools for woodworking projects as they help determine the moisture content of wood. High moisture content can lead to issues such as warping, shrinking, and cracking of the wood, making it crucial to have a reliable moisture meter for accurate readings.

There are two main types of moisture meters commonly used in woodworking:

Pin-type Moisture Meters

Pin-type moisture meters have two metal probes that are inserted into the wood to measure its moisture content. These meters work by transmitting an electrical current between the two probes. The resistance of the current is affected by the moisture content, giving the meter a reading.

Pin-type moisture meters are ideal for measuring the moisture content of thick wood, as the probes can penetrate deep into the material to provide accurate readings. However, they can leave small holes or marks in the wood, which may not be suitable for certain woodworking projects.

Pinless Moisture Meters

Pinless moisture meters, also known as non-destructive moisture meters, use sensors on the surface of the wood to measure its moisture content. These meters work by emitting electromagnetic waves that penetrate the wood and bounce back to the sensor. The moisture content is then calculated based on the wave’s reflection.

Pinless moisture meters are ideal for measuring moisture content without causing any damage to the wood surface. They are suitable for both rough and finished wood. However, they may not be as accurate as pin-type moisture meters when measuring the moisture content of thick wood.

Choosing the Right Moisture Meter

When choosing a moisture meter for woodworking, it is essential to consider the specific needs of your projects. Here are some factors to consider:

- The type of wood you frequently work with: Different wood species have different moisture content levels. Ensure that the moisture meter you choose has settings for the particular wood types you use.

- The desired accuracy of the moisture readings: Pin-type moisture meters tend to provide more accurate readings compared to pinless moisture meters. Consider your accuracy requirements before making a purchase.

- Your budget: Moisture meters come at varying price points. Determine your budget and look for a moisture meter that fits your needs and finances.

- Additional features: Some moisture meters come with additional features such as temperature measurement or data storage capabilities. Consider if these features are necessary for your woodworking projects.

Having a reliable moisture meter is crucial in woodworking to ensure the moisture content of the wood is suitable for the project at hand. Whether you choose a pin-type or pinless moisture meter, make sure to follow the manufacturer’s instructions for accurate and consistent readings.

Choosing the Right Moisture Content for Different Projects

When it comes to woodworking, choosing the right moisture content for your projects is crucial. The moisture content of wood affects its strength, stability, and overall quality. Different woodworking projects require different moisture content levels to ensure the best results. Here is a guide to help you choose the right moisture content for different types of woodworking projects.

1. Indoor Furniture:

For indoor furniture, a moisture content of around 6-8% is recommended. This level of moisture content ensures that the furniture remains stable and doesn’t warp or crack as it adjusts to indoor humidity levels. Kiln-dried wood is commonly used for indoor furniture projects as it provides a consistent moisture content.

2. Outdoor Furniture:

Outdoor furniture needs to withstand the elements, so a higher moisture content is required. A moisture content of 12-15% is suitable for outdoor furniture projects. This level of moisture content allows the wood to expand and contract with changes in humidity without causing damage.

3. Flooring:

When it comes to flooring, a moisture content of 6-9% is ideal. This level of moisture content ensures that the wood remains stable and won’t warp or buckle due to changes in humidity. It is important to acclimate the wood to the environment where it will be installed before laying it down to allow for proper moisture content adjustment.

4. Cabinetry:

For cabinetry projects, a moisture content of 6-8% is recommended. This level of moisture content ensures that the cabinets remain stable and won’t swell or shrink with changes in humidity. Kiln-dried wood is commonly used for cabinetry as it provides consistent moisture content.

5. Turning:

When it comes to wood turning projects, a moisture content of 10-15% is generally suitable. This level of moisture content allows the wood to be easily shaped and turned on a lathe. It is important to note that certain types of wood may require specific moisture content levels for best results.

6. Carving:

For carving projects, a moisture content of 8-12% is recommended. This level of moisture content allows the wood to be easily carved without compromising its structural integrity. Wood with too high or too low moisture content may be prone to splitting or cracking during carving.

Conclusion:

Choosing the right moisture content for your woodworking projects is essential for achieving optimal results. Whether you are working on indoor furniture, outdoor furniture, flooring, cabinetry, turning, or carving, understanding the ideal moisture content for each type of project will help you create durable and high-quality pieces.

Outdoor vs. Indoor Projects: Moisture Considerations

When choosing the right moisture content for woodworking projects, it is important to consider whether the project will be used outdoors or indoors. The environment in which the project will be used greatly impacts the moisture content that should be achieved before starting the project.

Outdoor Projects:

- Outdoor projects are exposed to various weather conditions, including rain, snow, and humidity.

- Exposure to moisture can cause wood to expand and contract, leading to warping, cracking, and decay.

- It is recommended to use wood with a moisture content of 12-15% for outdoor projects.

- Applying a waterproof finish or sealant can help protect the wood from moisture damage.

- Regular maintenance, such as resealing or refinishing, is necessary to ensure the longevity of outdoor projects.

Indoor Projects:

- Indoor projects are generally protected from extreme weather conditions, but they can still be affected by changes in humidity.

- Wood in indoor environments can absorb or release moisture depending on the humidity levels, leading to swelling or shrinking.

- It is recommended to use wood with a moisture content of 6-8% for indoor projects.

- Using kiln-dried wood or allowing the wood to acclimate to the indoor environment before starting the project can help minimize moisture-related issues.

- Applying a protective finish can also help stabilize the moisture content of indoor projects.

By considering the specific moisture considerations for outdoor and indoor projects, woodworkers can choose the appropriate moisture content that will result in a durable and long-lasting finished product.

Moisture Content for Furniture and Cabinetry

When it comes to woodworking projects such as furniture and cabinetry, moisture content is a crucial factor to consider. The right moisture content ensures that the wood is stable and durable, preventing issues like warping, splitting, and shrinking in the finished product. Here are some important points to keep in mind:

- Target moisture content: The ideal moisture content for furniture and cabinetry is typically around 6% to 8%. This range ensures that the wood is stable in most interior environments.

- Wood acclimation: Before using the wood, it’s important to acclimate it to its new environment. This involves allowing the wood to adjust to the humidity and temperature of the space where the finished product will be installed. This process helps prevent moisture-related issues later on.

- Initial moisture content: It’s important to know the initial moisture content of the wood before starting a project. This can be determined using a moisture meter, which measures the percentage of water in the wood. It’s recommended to select wood with a moisture content close to the target range.

- Seasoning the wood: If the initial moisture content of the wood is too high, it may need to be seasoned. Seasoning involves allowing the wood to dry slowly over time, either through air drying or kiln drying. This process removes excess moisture, reducing the risk of warping or shrinking.

- Controlling moisture content: To maintain the desired moisture content, it’s important to store the wood in a controlled environment. This can be achieved by storing it in a climate-controlled workshop or using moisture barriers such as plastic wrapping or wax coatings.

- Checking moisture levels: Regularly monitoring the moisture content of the wood throughout the project is essential. This can be done using a moisture meter or by observing signs of excess moisture, such as cupping or cracking. Adjustments can then be made as necessary.

By paying attention to moisture content, woodworkers can ensure that their furniture and cabinetry projects are built to last. Choosing the right moisture content and properly managing it throughout the woodworking process is key to preventing issues and creating high-quality, durable pieces.

FAQ:

Why is moisture content important in woodworking?

Moisture content is important in woodworking because it affects the stability and durability of the wood. Wood with high moisture content can warp, twist, or shrink as it dries, causing problems in the finished product.

What is the recommended moisture content for woodworking?

The recommended moisture content for woodworking varies depending on the specific project and type of wood being used. In general, a moisture content between 6% and 8% is considered ideal for most woodworking projects.

How can I measure the moisture content of wood?

There are several methods to measure the moisture content of wood, including using a moisture meter, oven-drying method, or electronic moisture balance. Each method has its own advantages and disadvantages and may be more suitable for different situations.

What problems can occur if the wood has too high moisture content?

If the wood has too high moisture content, it can lead to various problems in woodworking. The wood may warp, twist, or shrink as it dries, causing joints to loosen or break. It can also lead to mold and fungal growth, reducing the longevity of the finished product.

What problems can occur if the wood has too low moisture content?

If the wood has too low moisture content, it can become brittle and prone to cracking or splitting. This can weaken the overall structure of the woodworking project and make it less durable.

Does the moisture content of wood vary depending on the environment?

Yes, the moisture content of wood can vary depending on the environment. Wood will absorb moisture from the air in humid conditions and release moisture in dry conditions. It is important to acclimate the wood to the environment where it will be used to ensure the moisture content is stable.

What are some techniques for drying wood to achieve the desired moisture content?

There are several techniques for drying wood, including air drying, kiln drying, and using a dehumidifier. Air drying is the most natural and cost-effective method but can be time-consuming. Kiln drying is faster but requires specialized equipment. Using a dehumidifier can be a good option for small-scale projects.