Wood joinery is a timeless craft that has been practiced for centuries. It is the art of connecting pieces of wood together to create strong and beautiful structures. Whether you are a seasoned woodworker or just starting out, learning and mastering the various techniques of wood joinery can greatly enhance your woodworking projects.

In this ultimate guide, we will explore the different types of wood joinery techniques, from simple and beginner-friendly options to more complex and advanced methods. We will delve into the strengths and weaknesses of each technique, as well as provide tips and tricks to help you achieve precise and professional results.

From the classic mortise and tenon joint to the versatile dovetail joint, we will cover a wide range of joinery techniques that will expand your woodworking repertoire. Each technique will be explained in detail, with step-by-step instructions and accompanying illustrations.

Whether you are looking to construct furniture, cabinets, doors, or other woodworking projects, mastering the art of wood joinery will give your creations the durability and elegance they deserve. So grab your tools and let’s dive into the world of wood joinery!

Understanding Wood Joinery Basics

Wood joinery is a fundamental skill for any woodworker. It involves creating strong and secure connections between two or more pieces of wood, allowing them to function as one cohesive unit. Whether you’re building furniture, cabinets, or other woodworking projects, understanding the basics of wood joinery is essential.

Types of Wood Joints:

- Butt joint: This is the simplest and most basic type of joint where two pieces of wood are simply butted together. It is often reinforced with nails, screws, or dowels for added strength.

- Miter joint: A miter joint is made by cutting two pieces of wood at a 45-degree angle and joining them together to form a right angle. It is commonly used for picture frames and corners.

- Dovetail joint: The dovetail joint is a strong and decorative joint that interlocks wedge-shaped tails and pins. It is commonly used for drawers and boxes.

- Half-lap joint: This joint involves removing half the thickness of each piece of wood at the point where they will overlap. It creates a flush surface when the two pieces are joined together.

Joinery Techniques:

- Gluing: Using wood glue is one of the most common techniques for joining wood. It provides a strong bond when applied properly.

- Screwing: Screws are often used in conjunction with other joinery methods to provide additional strength and stability.

- Doweling: Dowels are cylindrical pieces of wood or metal that can be used to reinforce joints. They are inserted into pre-drilled holes and provide added strength.

- Biscuit joining: Biscuit joinery involves cutting a slot in each piece of wood and inserting a wooden biscuit coated in glue. This technique is commonly used for aligning and reinforcing edge-to-edge joints.

Factors to Consider:

When deciding which wood joinery technique to use, there are several factors to consider:

- Strength: Depending on the intended use of the project, you’ll want to choose a joinery method that provides the necessary strength and durability.

- Aesthetics: Some joinery techniques, such as dovetail joints, can add a decorative element to your project.

- Complexity: The complexity of the joint and the tools required should be taken into account, especially if you’re a beginner woodworker.

- Cost and time: Certain joinery techniques may require specialized tools or materials, which can impact the overall cost and time required for the project.

By understanding the basics of wood joinery and considering these factors, you’ll be well-equipped to choose the right techniques for your woodworking projects and create strong, durable, and beautiful pieces.

Choosing the Right Wood for Joinery

When it comes to wood joinery, selecting the right type of wood is crucial for the success and durability of your project. The type of wood you choose will depend on several factors, including the purpose of the joint, the aesthetic you want to achieve, and the tools and techniques you plan to use.

Here are some factors to consider when choosing the right wood for joinery:

Strength and Durability

One important consideration is the strength and durability of the wood. Different types of wood have varying levels of hardness and resistance to wear and tear. For joints that require extra strength, such as mortise and tenon joints, you’ll want to choose a hardwood like oak or maple. These woods are known for their strength and ability to withstand stress over time.

On the other hand, softer woods like pine or cedar may be suitable for less demanding joints or decorative purposes. Keep in mind that softer woods may be more prone to damage and wear, so they might not be the best choice for high-stress joints.

Appearance

The appearance of the wood is another important factor to consider, especially if you’re aiming for a specific aesthetic. Some woods, like walnut or cherry, are known for their rich, warm tones and beautiful grain patterns. These woods can add a touch of elegance and sophistication to your joinery projects. Alternatively, you may opt for lighter woods like birch or maple for a more contemporary or minimalist look.

It’s also worth considering the natural color and finish of the wood. Some woods have a natural reddish hue, while others may have a more yellow or brown tone. Choosing a wood that complements your overall design vision will ensure that your joinery work stands out.

Availability and Cost

The availability and cost of the wood are practical factors that cannot be overlooked. Some types of wood may be more readily available in your local area, while others might need to be sourced from specialty suppliers. Keep in mind that certain types of wood can be expensive, so you’ll need to factor in your budget when making a decision. Additionally, consider whether the wood is sustainably sourced to minimize the impact on the environment.

Workability

Finally, consider the workability of the wood. Different woods have different properties when it comes to cutting, shaping, and joining. Some woods may be prone to splintering or tearing, while others are more forgiving and easier to work with. The workability of the wood will impact the tools and techniques you choose for your joinery projects, as well as the overall ease and speed of completion.

Ultimately, choosing the right wood for joinery involves considering a combination of strength, appearance, availability, cost, and workability. By carefully evaluating these factors, you’ll be able to select the best wood for your specific joinery needs.

Essential Tools for Wood Joinery

Wood joinery is a craft that requires precision and skill, and having the right tools is essential to achieve high-quality and reliable joints. Whether you are a beginner or an experienced woodworker, there are several tools that you should have in your workshop to successfully execute different joinery techniques. Here are some of the essential tools for wood joinery:

- Chisels: Chisels are indispensable tools for wood joinery. They are used to remove wood and create clean and precise cuts. It’s essential to have a variety of chisels in different sizes to handle different joinery tasks.

- Router: A router is a versatile tool that can be used for a wide range of joinery tasks, such as creating dadoes, rabbets, and grooves. It allows you to make precise and accurate cuts with ease.

- Dovetail saw: Dovetail saws are specifically designed for cutting dovetail joints. They have a thin blade with fine teeth that enable you to make precise cuts, ensuring a tight and secure joint.

- Marking and measuring tools: Accurate measurements are crucial in wood joinery, and having the right marking and measuring tools is essential. Tools like a marking gauge, combination square, and tape measure will help you achieve precise cuts and joints.

- Clamps: Clamps are essential for holding the wood pieces together during the joinery process. They ensure that the joints remain tight and secure while the glue dries. Having a variety of clamps in different sizes and types will give you flexibility in your projects.

- Bench plane: A bench plane is used to smooth and flatten wood surfaces, ensuring that the joints fit together tightly. It is essential to have a well-sharpened and properly adjusted bench plane for achieving smooth and accurate joints.

- Joinery jigs: Joinery jigs are specialized tools that help you create consistent and accurate joints. They can be used for various joinery techniques, such as mortise and tenon joints or dovetail joints. Having a few well-designed jigs can significantly simplify the joinery process.

- Drill and drill bits: A drill is essential for creating holes for screws or dowels in joinery projects. Having a set of quality drill bits in different sizes will allow you to make precise holes for different types of joinery connections.

These are just some of the essential tools for wood joinery. As you continue to explore and master the art of wood joinery, you may find yourself adding more specialized tools to your collection. However, starting with these foundational tools will set you up for success in your woodworking projects.

Traditional Wood Joinery Techniques

Wood joinery is an essential skill for any woodworker or carpenter. It involves attaching two or more pieces of wood together to create a strong and stable joint. Traditional wood joinery techniques have been used for centuries and are still widely practiced today. These techniques often require precision, patience, and a steady hand to create seamless and durable connections.

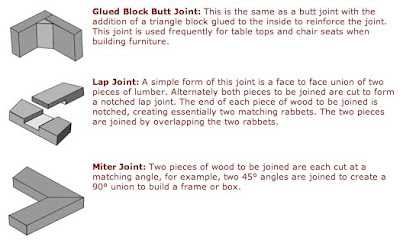

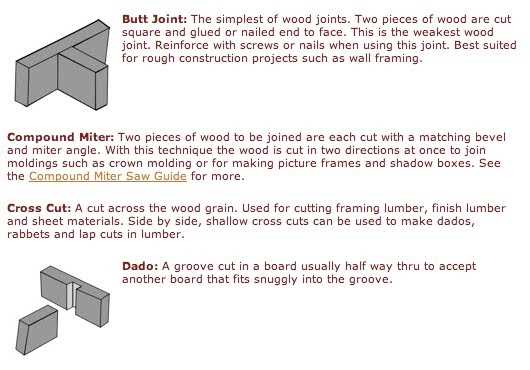

1. Butt Joint

A butt joint is the most basic and simplest type of joint. It involves joining two pieces of wood by simply placing their ends together. This joint can be reinforced with glue and fasteners such as nails or screws. However, it is not the strongest joint and is mainly used when the joint will be hidden or covered.

2. Miter Joint

The miter joint is commonly used in frame construction and trim work. It is created by cutting the ends of two pieces of wood at a 45-degree angle and joining them together. This joint creates a neat and seamless look when the two pieces are assembled. Reinforcement with glue and splines or biscuits can add extra strength to the joint.

3. Dovetail Joint

The dovetail joint is known for its strength and aesthetic appeal. It is commonly used in cabinetmaking and furniture construction. This joint involves cutting alternating pins and tails in the two pieces of wood to interlock them together. The interlocking shape prevents the joint from pulling apart and adds mechanical strength. Dovetail joints are often seen on drawers and boxes.

4. Mortise and Tenon Joint

The mortise and tenon joint is one of the oldest and strongest wood joinery techniques. It involves cutting a slot (mortise) in one piece of wood and inserting a projecting piece (tenon) from another piece of wood into the slot. This joint can be used for various applications, including furniture, doors, and window frames. It provides excellent strength and stability when properly executed.

5. Half-Lap Joint

The half-lap joint is a versatile joint commonly used in woodworking. It involves removing half the thickness of each piece of wood at the point where they will be joined, creating a flush and seamless connection. This joint can be used for making table legs, frames, and cabinet joinery. It offers good strength when reinforced with glue and fasteners.

6. Tongue and Groove Joint

The tongue and groove joint is frequently used in flooring, paneling, and carpentry. It involves cutting a narrow protruding section (tongue) on one piece of wood that fits into a corresponding groove cut on the other piece of wood. This joint provides a tight fit and prevents movement between the joined pieces. It can be enhanced with glue or nails for added strength.

7. Dowel Joint

The dowel joint involves drilling matching holes in two pieces of wood and inserting dowels into the holes to connect them. This joint is commonly used as an alternative to screws or nails, providing additional strength and a cleaner appearance. Dowel joints are often used in furniture construction and can be reinforced with glue.

8. Bridle Joint

The bridle joint is a strong and decorative joint commonly used in frame construction and cabinetry. It involves cutting a notch (mortise) on one piece of wood and creating a projecting tenon on the other piece that fits into the mortise. This joint provides good strength and can be reinforced with glue and fasteners.

Conclusion

These traditional wood joinery techniques offer a range of options for creating strong and aesthetically pleasing connections between pieces of wood. Each technique has its own advantages and is suitable for different applications. Mastering these techniques requires practice and attention to detail, but the results are well worth the effort. So, whether you’re a beginner or an experienced woodworker, explore the world of traditional wood joinery and elevate your woodworking projects to new levels of craftsmanship.

Advanced Wood Joinery Methods

Once you have mastered the basics of wood joinery, you may be ready to explore more advanced techniques. These methods require a higher level of skill and precision, but they can create incredibly strong and visually stunning joints. Here are a few advanced wood joinery methods that you can add to your repertoire:

Dovetail Joints

Dovetail joints are known for their incredible strength and beauty. They are commonly used in cabinet making and fine furniture construction. Dovetail joints consist of interlocking trapezoidal pins and tails, which create a solid connection. To create a dovetail joint, you will need to mark out and carefully cut the pins and tails, ensuring a tight fit.

Mortise and Tenon Joints

Mortise and tenon joints are another popular method for joining wood. This joint consists of a rectangular hole (mortise) and a corresponding projection (tenon). The tenon is inserted into the mortise and secured with glue or wooden pins. Mortise and tenon joints provide excellent strength and stability, making them suitable for heavy-load applications such as table legs.

Finger Joints

Finger joints, also known as box joints, are often used for creating strong and decorative corners in boxes and drawers. This joint consists of interlocking rectangular sections that resemble interlaced fingers when assembled. Finger joints can be created using a table saw or a router with a jig. They provide a large gluing surface area, resulting in a sturdy joint.

Tongue and Groove Joints

Tongue and groove joints are commonly used for joining boards together to create wider panels, such as flooring or tabletops. This joint consists of a groove cut in one board and a corresponding tongue cut in the other board. The tongue of one piece fits into the groove of the other, creating a strong and seamless connection. Tongue and groove joints also help to prevent warping and movement in the joined boards.

Dado Joints

Dado joints are often used in cabinets and shelving to join horizontal and vertical pieces of wood. This joint consists of a rectangular groove cut into one piece of wood, which allows another piece of wood to fit snugly inside. Dado joints provide a strong connection and are commonly secured with glue or screws.

Bridle Joints

Bridle joints, also known as open mortise and tenon joints, are used for joining two pieces of wood at a right angle. They are similar to mortise and tenon joints but have visible shoulders. This joint consists of a mortise cut in one piece and a tenon cut in the other, creating a clean and visually appealing joint. Bridle joints are often used in furniture frames and chair construction.

These are just a few examples of advanced wood joinery methods that you can explore. Each joint requires careful planning, accurate measurements, and the use of specialized tools. By mastering these techniques, you can take your woodworking skills to the next level and create beautiful, durable projects.

Common Wood Joinery Mistakes and How to Avoid Them

Joinery is a critical aspect of woodworking, allowing you to create strong and durable connections between wooden pieces. However, even experienced woodworkers can make mistakes during the joinery process. Here are some common wood joinery mistakes and tips on how to avoid them:

- Poor measurement and inaccurate marking: One of the most frequent mistakes in woodworking is failing to measure and mark accurately. This can lead to ill-fitting joints and uneven connections. To avoid this, use reliable measuring tools such as a combination square or tape measure. Double-check your measurements before making any cuts, and always use sharp marking tools like a pencil or knife to ensure precise markings.

- Choosing the wrong joinery technique: Selecting the appropriate joinery technique for your project is crucial. Using a weak or unsuitable joint can result in joints that fail over time. Research and experiment with different joinery methods, such as dovetails, mortise and tenon, or dowel joints, to determine the most appropriate for your specific woodworking project. Consider the type of wood, the desired joint strength, and the overall design when making your decision.

- Not practicing proper clamping: Insufficient clamping can lead to gaps, misalignment, and weak joints. It’s essential to apply consistent pressure when clamping your pieces together to ensure a tight and secure joint. Use clamps that are appropriate for the size and type of joint you are creating, and distribute the clamping pressure evenly. Periodically check the alignment and adjust the clamps as necessary during the drying process.

- Ignoring wood grain direction: Neglecting to consider the direction of the wood grain when creating joints can result in weak connections and potential wood movement issues. Always align the grain direction across the joint to maximize joint strength and prevent wood movement-related problems like warping or splitting. Take the time to understand the grain patterns and adjust your joinery accordingly.

- Using improper cutting techniques: Incorrect cutting techniques can compromise the accuracy and quality of your joints. Avoid rushing or applying too much force when making cuts, as this can cause tear-out or uneven surfaces. Use appropriate saws and chisels with sharp blades to achieve clean and precise cuts. Take your time, follow the correct cutting techniques, and practice on scrap wood before attempting complicated joinery tasks.

Avoiding these common wood joinery mistakes will help improve the quality and longevity of your woodworking projects. Remember to invest time in planning, practicing, and learning from experienced woodworkers to develop your joinery skills. With patience and attention to detail, you can create strong and beautiful wood joinery connections.

Tips and Tricks for Achieving Perfect Wood Joints

Mastering the art of wood joinery requires precision, patience, and a keen eye for detail. Here are some expert tips and tricks to help you achieve perfect wood joints:

- Choose the right type of joint: Different types of joints work best for different applications. Consider factors such as the strength required, aesthetic appeal, and the type of wood you are working with.

- Use sharp tools: Dull tools can result in sloppy joints. Ensure your chisels, planes, and saw blades are sharp before starting any project.

- Measure twice, cut once: Accurate measurements are essential for seamless joints. Take the time to double-check your measurements before making any cuts.

- Practice proper clamping: Proper clamping ensures that the joint remains stable while the glue dries. Use clamps to apply even pressure and prevent any shifting.

- Create clean and smooth surfaces: Before joining two pieces of wood, make sure the surfaces are clean and smooth. Sand or plane them if necessary to ensure a tight fit.

- Apply the right amount of glue: Applying too much glue can result in a messy joint, while too little glue may result in a weak bond. Use a brush or roller to evenly distribute the adhesive.

- Know your wood grain: Understanding the direction of the wood grain is crucial for achieving strong and visually appealing joints. Align the grain for maximum strength.

- Practice proper assembly techniques: Whether it’s dovetail joints, mortise and tenon joints, or box joints, practice proper assembly techniques to ensure a tight and secure fit.

- Take your time: Rushing through a project can lead to mistakes and compromised joints. Take your time, work methodically, and pay attention to detail.

- Experiment and learn from mistakes: Wood joinery is a skill that improves with practice. Don’t be afraid to experiment with new techniques and learn from any mistakes you make along the way.

By following these tips and tricks, you’ll be well on your way to mastering the art of wood joinery and achieving flawless wood joints in your projects.

Applying Wood Joinery in DIY Projects

Wood joinery techniques are essential for any DIY enthusiast looking to create beautiful and functional pieces of furniture or woodworking projects. By mastering the art of wood joinery, you can ensure that your projects are not only aesthetically pleasing but also strong and durable.

Here are some key ways you can apply wood joinery in your DIY projects:

1. Butt Joint

A butt joint is one of the simplest and most common methods of joining two pieces of wood together. It involves joining the end of one piece of wood to the face or edge of another piece. While it may not be the strongest joint, it can be reinforced with screws, dowels, or biscuits for added stability.

2. Miter Joint

A miter joint is commonly used in picture frames, molding, and other decorative pieces. It involves joining two pieces of wood at a 45-degree angle to create a clean and seamless corner. To strengthen the joint, you can use glue and reinforce it with splines or dowels.

3. Dovetail Joint

The dovetail joint is known for its strength and durability. It involves interlocking wedge-shaped tails on one piece of wood with corresponding notches on another piece. This joint is often used in drawer construction, ensuring that the sides and front of the drawer remain securely attached.

4. Mortise and Tenon Joint

The mortise and tenon joint is another strong and versatile method of joining wood. It involves creating a mortise (a hole) in one piece of wood and a corresponding tenon (a projecting piece) on another piece. This joint is commonly used in furniture construction and can be reinforced with glue or dowels for added strength.

5. Dado Joint

A dado joint is commonly used for joining shelves to the sides of cabinets or bookcases. It involves creating a groove or channel in one piece of wood that can accommodate the thickness of another piece. This joint provides stability and helps prevent shelves from sagging under heavy loads.

When applying wood joinery in your DIY projects, it’s important to choose the appropriate joint for the specific task at hand. Consider factors such as the type of wood, the weight-bearing requirements, and the overall design aesthetic you wish to achieve. By understanding and using different wood joinery techniques, you can create stunning and durable pieces of furniture and woodworking projects that showcase your craftsmanship.

FAQ:

What is wood joinery?

Wood joinery is the craft of connecting two or more pieces of wood together to create a structurally sound and visually appealing object. It involves various techniques and methods that ensure a strong bond between the pieces of wood.

What are some common wood joinery techniques?

There are several common wood joinery techniques, including dovetail joints, mortise and tenon joints, finger joints, and dowel joints. Each technique has its own strengths and weaknesses and is suited for different applications.

What tools are needed for wood joinery?

Wood joinery requires a variety of tools, depending on the technique being used. Some essential tools include chisels, saws, a mallet or hammer, a marking gauge, and a square. Additionally, clamps and adhesive may be needed for certain types of joints.

What are some tips for achieving a perfect wood joint?

To achieve a perfect wood joint, it is important to carefully measure and mark the wood, use sharp and properly maintained tools, and have a good understanding of the chosen joinery technique. It is also important to practice and refine your skills over time. Additionally, using high-quality wood and ensuring a tight fit between the pieces will result in a stronger joint.