Knitting is an ancient craft that has been practiced by humans for centuries. Traditionally, knitting was done by hand using two knitting needles to create intricate patterns and designs. However, with the advent of technology, knitting can now be done by machines. This has sparked a debate among knitting enthusiasts and purists about the pros and cons of machine knitting.

On one hand, machine knitting offers several advantages. Firstly, it allows for faster production of knitted items. Machine knitting can produce hundreds of stitches per minute, significantly speeding up the knitting process. This is particularly beneficial for large-scale production or when making multiple identical items. Additionally, machine knitting can produce more uniform stitches and tension compared to hand knitting, resulting in a more professional and polished look.

However, there are also drawbacks to machine knitting. Some argue that machine knitting lacks the personal touch and artistic expression that comes with hand knitting. Hand-knitted items often have a unique and individual quality, with slight variations in stitches and tension that add to their charm. Machine knitting, on the other hand, can sometimes result in a more standardized and mass-produced appearance. Additionally, machine knitting requires specialized equipment and knowledge, which can be costly and inaccessible to some.

In conclusion, machine knitting offers speed, efficiency, and precision, while hand knitting provides a personal, artistic touch. Ultimately, the choice between machine knitting and hand knitting depends on the individual’s preferences and goals. Some may prefer the convenience and speed of machine knitting, while others may value the craftsmanship and individuality of hand knitting. Regardless of the method chosen, knitting remains a versatile and beloved craft that continues to evolve with technology.

Understanding Knitting by Machine

Knitting by machine is a process in which a knitting machine is used to create fabric or garments. Unlike hand knitting, which requires manual manipulation of the yarn, knitting by machine automates the process and can produce fabric at a much faster rate.

Types of knitting machines:

There are two main types of knitting machines: flatbed machines and circular machines.

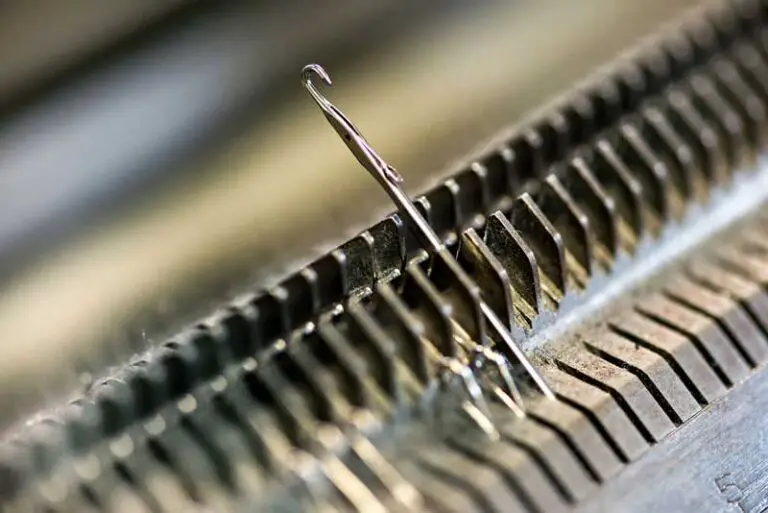

- Flatbed machines: These machines have a flat surface with needles arranged in a straight line. The fabric is knitted flat and then can be seamed together to create garments or other items.

- Circular machines: These machines have needles arranged in a circular shape, allowing for continuous knitting in the round. This is commonly used for creating seamless garments like hats or socks.

How knitting machines work:

Knitting machines work by using a series of needles to create loops of yarn. These loops are then linked together to form a fabric. The machine can be programmed to create various patterns and designs by controlling the movement of the needles.

Benefits of knitting by machine:

- Speed: Knitting by machine is much faster than hand knitting, allowing for the production of larger quantities of fabric in a shorter amount of time.

- Precision: Machines can produce very precise and consistent stitches, resulting in a well-finished fabric or garment.

- Complexity: Knitting machines can easily create complex stitch patterns and designs that would be difficult or time-consuming to achieve by hand.

Limitations of knitting by machine:

- Creativity: Hand knitting allows for more creativity and freedom to experiment with various stitch patterns and designs.

- Cost: Knitting machines can be expensive to purchase and maintain, making them less accessible for individual knitters.

- Technical skill: Operating a knitting machine requires technical knowledge and skill, which can be a barrier for beginners.

Conclusion:

Knitting by machine offers numerous advantages in terms of speed, precision, and complexity. However, it also has limitations in terms of creativity, cost, and required technical skill. Ultimately, the choice between hand knitting and knitting by machine depends on the individual’s needs, preferences, and goals.

Advantages of Knitting by Machine

Knitting by machine offers several advantages over hand-knitting. These include:

- Increased speed: Knitting by machine is significantly faster than hand-knitting. Machines can produce garments and fabrics at a much higher rate, which is especially beneficial for large-scale production.

- Consistency and precision: Machines ensure consistent tension and stitch formation, resulting in a more uniform and professional-looking finished product. This is particularly important for items such as sweaters, where symmetry and precise stitch counts are crucial.

- Complexity: Knitting machines have the ability to create intricate patterns, colorwork, and textures that would be difficult or time-consuming to achieve by hand. This allows for the production of more elaborate and visually appealing designs.

- Efficiency: With automated functions and programmable patterns, knitting machines eliminate the need for manual stitch counting and tracking. This saves time and reduces the chances of errors, making the process more efficient and less prone to mistakes.

- Innovation and experimentation: Machine knitting opens up new possibilities for innovation and experimentation, as designers can explore new techniques and materials that are better suited for machine production. This can lead to the development of unique and avant-garde designs.

While machine knitting offers numerous advantages, it is important to note that it also has some drawbacks. These include the initial cost of purchasing a machine, the need for technical expertise in operating and maintaining the equipment, and the potential limitations on creativity compared to the versatility of hand-knitting.

Overall, machine knitting provides a valuable alternative for mass production, efficiency, and the creation of complex designs. It complements and coexists with hand-knitting, allowing for a diverse and dynamic knitting industry.

Disadvantages of Knitting by Machine

- High cost: Knitting machines can be quite expensive, especially the more advanced models. This can make them inaccessible for many individuals or small businesses.

- Limited design capabilities: While knitting machines offer great efficiency, they may not be able to replicate complex or intricate designs as well as handmade knitting. The machines are limited by their programming and may not be able to create unique or customized patterns.

- Difficulty in repairs and maintenance: Knitting machines are complex devices that require regular maintenance and occasional repairs. Finding skilled technicians who can service the machines can be challenging, especially in remote areas.

- Less flexibility and creativity: Hand knitting allows for a lot of creativity and spontaneity as the knitter can easily change patterns or adjust the design as they go along. Machine knitting, on the other hand, requires meticulous pre-planning and may not allow for improvisation or experimentation.

- Less personal touch: Handmade knitted items often carry a personal touch and emotional value that can be lacking in machine-knit products. The process of knitting by hand is often regarded as a labor of love, whereas machine-knit items can feel more impersonal or mass-produced.

- Dependency on electricity: Knitting machines require electricity to operate, which means they are not suitable for areas with unreliable power supply or in situations where electricity is unavailable.

- Environmental impact: The mass production of machine-knit items can contribute to environmental issues, such as excessive energy consumption and waste generation. Hand knitting, on the other hand, tends to be more sustainable and eco-friendly.

Quality and Detail in Machine Knitting

Machine knitting has come a long way in terms of quality and detail. While hand knitting is known for its intricate and delicate designs, machine knitting has the ability to produce high-quality and finely detailed garments in a fraction of the time.

One of the advantages of machine knitting is its ability to create consistent and uniform stitches. This results in a more professional and polished finish compared to hand knitting. The precision of machine knitting ensures that each stitch is the same size, resulting in a neater and more even fabric.

Machine knitting also allows for intricate patterns and designs to be created with ease. With hand knitting, complex patterns can be time-consuming and require a lot of concentration. On the other hand, machine knitting allows these intricate patterns to be achieved quickly and easily, making it ideal for creating elaborate and detailed garments.

In addition to speed and efficiency, machine knitting also offers a wider range of possibilities in terms of stitch patterns and techniques. Various types of stitches, such as cables, lace, and colorwork, can be easily created using a knitting machine. This opens up a world of creativity and allows for endless design possibilities.

However, it is worth noting that machine knitting does have its limitations when it comes to quality and detail. While it can produce intricate patterns, the level of intricacy achieved by hand knitting is unmatched. Hand knitting allows for more control over the tension and placement of each stitch, resulting in more intricate and precise designs.

Overall, machine knitting offers a balance between speed, efficiency, and quality. While it may not be able to replicate the level of detail achieved by hand knitting, it offers a level of precision and consistency that is difficult to achieve by hand. Whether it is for producing large quantities of garments or creating complex patterns, machine knitting is a valuable tool for achieving high-quality and detailed knitted items.

Traditional Knitting vs Machine Knitting

Knitting is a craft that has been practiced for centuries, and it has traditionally been done by hand. However, with the invention of knitting machines, the process of creating knitted garments has been revolutionized. Here, we will explore the differences between traditional knitting and machine knitting.

1. Skill Level: Traditional knitting requires manual dexterity and skill. It involves creating intricate stitches using knitting needles and requires a good understanding of knitting techniques. On the other hand, machine knitting requires less manual skill as the machine does most of the work. However, operating and maintaining the knitting machine does require some technical knowledge.

2. Speed and Efficiency: Machine knitting is significantly faster than traditional knitting. A knitting machine can produce garments at a much faster rate compared to hand-knitting, making it more efficient for large-scale production. This makes machine knitting a preferred choice for commercial manufacturers and businesses.

3. Customization: Traditional knitting allows for more customization and creative freedom. Knitters can choose from a wide range of yarns, stitches, and patterns to create unique and personalized garments. Machine knitting, on the other hand, is limited in terms of customization as the designs and patterns are often pre-programmed into the machine.

4. Quality: Traditional knitting is often associated with high-quality craftsmanship. Hand-knitted garments are known for their attention to detail and unique texture. Machine knitting, while fast and efficient, may not always produce the same level of quality as traditional knitting. However, advancements in technology have led to improved machine-knitted garments with better quality finishes.

5. Cost: Machine knitting can be more cost-effective compared to traditional knitting, especially for large-scale production. The speed and efficiency of knitting machines can help reduce labor costs, making it a more economical option. Traditional knitting, on the other hand, requires more time and skill, making it more costly in terms of labor.

In conclusion, both traditional knitting and machine knitting have their advantages and disadvantages. Traditional knitting offers customization, high-quality craftsmanship, and creative freedom, while machine knitting offers speed, efficiency, and cost-effectiveness. The choice between the two depends on the desired outcome, scale of production, and personal preferences.

Economic and Environmental Impact of Machine Knitting

Machine knitting has both economic and environmental implications. Here are some key points to consider:

- Increased production efficiency: Machine knitting allows for faster and more efficient production compared to hand knitting. This can result in increased productivity and reduced labor costs for manufacturers.

- Lower costs: Machine knitting can lead to lower costs for consumers due to decreased labor requirements and increased production scale.

- Job displacement: The widespread adoption of machine knitting can lead to job displacement in the hand-knitting industry. While machines can produce items at a faster rate, they also eliminate the need for manual labor, potentially reducing employment opportunities for hand knitters.

- Environmental impact: Machine knitting can have a lower environmental impact compared to hand knitting. Machines can use less energy and produce less waste compared to manual knitting processes.

- Resource usage: Machine knitting requires the use of raw materials such as yarns and fabrics. The increased production volume associated with machine knitting can lead to higher resource consumption.

- Waste management: Machine knitting can generate waste in the form of excess yarns and fabrics. Proper waste management practices are essential to minimize the environmental impact.

- Potential for innovation: Machine knitting technology continues to evolve, leading to new possibilities in design and production. This can open up opportunities for creativity and innovation in the fashion industry.

In conclusion, machine knitting offers various economic advantages, such as increased efficiency and lower costs. However, it also presents challenges such as job displacement and potential environmental impacts. Balancing these factors is crucial in order to fully understand the implications of machine knitting in the fashion industry.

Machine Knitting and Customization

Machine knitting has brought new levels of customization to the knitting world. With traditional hand knitting, the final product is limited by the skill and speed of the knitter. However, machine knitting allows for greater precision and consistency, resulting in more complex and intricate designs.

One of the biggest advantages of machine knitting is the ability to easily reproduce patterns. Once a design is programmed into a knitting machine, it can be replicated over and over again with minimal effort. This makes machine knitting ideal for creating large quantities of items, such as sweaters or scarves, for sale.

Machine knitting also offers the possibility of creating highly detailed and complicated designs that would be very time-consuming or even impossible to achieve by hand. The machines can knit intricate lace patterns, complex colorwork, and even images. This opens up a whole new world of creativity for designers and allows for customization on a whole new level.

Furthermore, machine knitting allows for faster production times compared to hand knitting. This is especially beneficial for commercial purposes, where quick turnaround times are often required. By using machines, manufacturers can produce items at a much faster rate, meeting the demands of the market.

However, there are some limitations to customization when it comes to machine knitting. Unlike hand knitting, where each stitch is individually controlled by the knitter, machine knitting operates on a set of programmed instructions. This means that the machine can only produce what it has been programmed to do.

Additionally, certain techniques or effects that are achievable by hand may be difficult or impossible to replicate with a machine. For example, hand-knitted items often have a unique texture or feel that can be hard to recreate with a machine. This can result in a loss of the personal touch and craftsmanship that is often associated with hand-made knitted items.

In conclusion, machine knitting offers a range of benefits with regard to customization. It allows for the replication of patterns, the creation of intricate designs, and faster production times. However, it does come with some limitations in terms of the personal touch and unique qualities that can be achieved with hand knitting.

FAQ:

Can knitting be done by machine?

Yes, knitting can be done by machine. In fact, machine knitting is a common method of mass-producing knitted items such as sweaters, socks, and blankets.

What are the advantages of machine knitting?

Machine knitting offers several advantages. Firstly, it allows for fast and efficient production of knitted items. Machines can produce knitting at a much faster rate than humans, increasing productivity. Additionally, machine knitting ensures consistency and uniformity in the finished product. Machines are programmed to follow specific patterns and produce identical garments, reducing variations and errors. Finally, machine knitting can be less physically demanding compared to hand knitting, as it eliminates the repetitive strain on the hands and wrists.

Are there any disadvantages to machine knitting?

While machine knitting has many advantages, there are also some disadvantages. One of the main drawbacks is the lack of versatility and creativity. Machines are limited in their ability to create complex designs and intricate stitch patterns. Hand knitting allows for more freedom and flexibility in creating unique and personalized items. Additionally, machine knitting requires specialized equipment and skills, which can be costly and require training. Finally, some people argue that machine knitting lacks the charm and individuality of handmade items.

Is machine knitting more cost-effective than hand knitting?

Generally, machine knitting is more cost-effective than hand knitting for mass production. Machines can produce large quantities of knitted items in a shorter amount of time, reducing labor costs. The cost of materials and maintenance of the machines can also be spread out over a larger production volume, further lowering the cost per item. However, for small-scale production or one-of-a-kind items, hand knitting may be more cost-effective, as it eliminates the need for expensive machinery and allows for more customization.