Creating pottery is a beautiful and ancient art form that allows for endless creativity and expression. One of the techniques used in pottery making is the use of a press mold. A press mold is a tool that is used to shape clay into specific forms and designs. By using a press mold, you can easily create consistent and repeatable shapes for your pottery.

To use a press mold, you will need some basic pottery supplies including clay, a press mold of your choice, and a rolling pin or slab roller. The first step is to prepare your clay by kneading it to remove air bubbles and make it more pliable. Once the clay is ready, place it on a smooth, clean surface.

Next, take your press mold and dust it with some cornstarch or talcum powder to prevent the clay from sticking. Press your clay into the mold, making sure to evenly distribute it and fill all the crevices. Use your fingers or a small tool to firmly press the clay into the mold, ensuring that it takes on the desired shape and detail.

Once the mold is filled, carefully remove any excess clay from the edges using a knife or scraper. Then, gently release the clay from the mold by tapping it or using a releasing agent. At this point, you can smooth the surface of your pottery using a sponge or other smoothing tool. Allow the clay to dry completely before removing it from the mold and firing it in a kiln.

Using a press mold in pottery making can save you time and effort, while also providing consistent and professional-looking results. With practice, you can experiment with different molds and techniques to create unique and stunning pieces of pottery. So go ahead, give it a try and let your creativity flow!

What is a Press Mold?

A press mold is a tool used in pottery making to create consistent and uniform shapes. It is a form or template that is used to shape clay into desired forms. Press molds can be made from various materials such as plaster, wood, or even flexible silicone.

Press molds are commonly used in the production of pottery because they allow for the creation of identical pieces with ease. They are particularly useful for creating items with intricate designs or patterns, as the mold can be carved or etched to transfer the design onto the clay.

These molds work by pressing clay into the mold and removing excess clay to reveal the desired shape. They can be used for both hand-building techniques, where clay is shaped by hand, and wheel-throwing techniques, where clay is shaped on a pottery wheel.

Press molds come in a variety of shapes and sizes, allowing potters to create a range of objects such as bowls, plates, vases, and more. They can also be customized to create unique and personalized pieces of pottery.

Overall, press molds are an essential tool for potters, as they provide a convenient and efficient way to create consistent and detailed pottery pieces. They save time and effort, while also allowing for greater creativity and precision in pottery making.

Step 1: Gathering Supplies

To start using a press mold to make pottery, you will need to gather the following supplies:

- Press mold: Choose a press mold that suits your desired shape or design. Press molds are typically made of plaster, wood, or other materials and come in various sizes and designs.

- Pottery clay: Select a suitable pottery clay for your project. There are different types of clay available, such as earthenware, stoneware, and porcelain. Choose a clay that is compatible with your firing process.

- Water: Have water on hand to moisten the clay and prevent it from drying out during the molding process.

- Clay tools: Use various clay tools like a clay knife or needle tool for trimming and detailing the clay.

- Rolling pin or slab roller: Use a rolling pin or slab roller to roll out the clay into a flat slab that will be placed in the press mold.

- Plastic wrap: Cover the press mold with plastic wrap to prevent the clay from sticking to the mold.

- Craft knife or wire cutter: Use a craft knife or wire cutter to cut away excess clay from the molded piece.

- Drying rack or surface: Prepare a drying rack or surface where you can place the molded clay to dry before firing.

Once you have gathered all the necessary supplies, you are ready to move on to the next step of the process.

Clay

Introduction

Clay is a versatile material that has been used for thousands of years to create pottery. It is a type of soil or sediment that is rich in minerals, particularly aluminum and silicon. When water is added to clay, it becomes malleable and can be shaped into various forms.

Types of Clay

There are different types of clay that can be used for pottery making, including:

- Earthenware clay: This is a low-fire clay that is often used for functional pottery, such as dishes and bowls. It is more porous than other clays, which makes it ideal for glazing.

- Stoneware clay: This is a high-fire clay that is great for making durable pottery. It is less porous than earthenware clay and can withstand higher temperatures.

- Porcelain clay: This is a white clay that is known for its translucency when fired. It is often used for delicate and intricate pottery pieces.

Preparing Clay

Before using clay, it needs to be prepared to remove any impurities and make it easier to work with. Here are the basic steps for preparing clay:

- Wedging: Wedging is a process of kneading and mixing the clay to remove air bubbles and ensure an even consistency. It can be done by hand or using a wedging table.

- Drying: After wedging, the clay needs to be dried to a certain moisture level. This can be done by allowing it to air dry or using a drying box.

- Reclaiming: If any clay scraps or unwanted pieces are leftover, they can be reclaimed by adding water and breaking the clay down into a slurry.

Working with Clay

Once the clay is prepared, it can be shaped into pottery using various techniques, such as:

- Handbuilding: Handbuilding involves shaping clay by hand, without the use of a pottery wheel. Techniques like pinch pots, coil building, and slab construction can be used.

- Wheel throwing: Wheel throwing is done using a pottery wheel, which allows for creating symmetrical and balanced pottery forms.

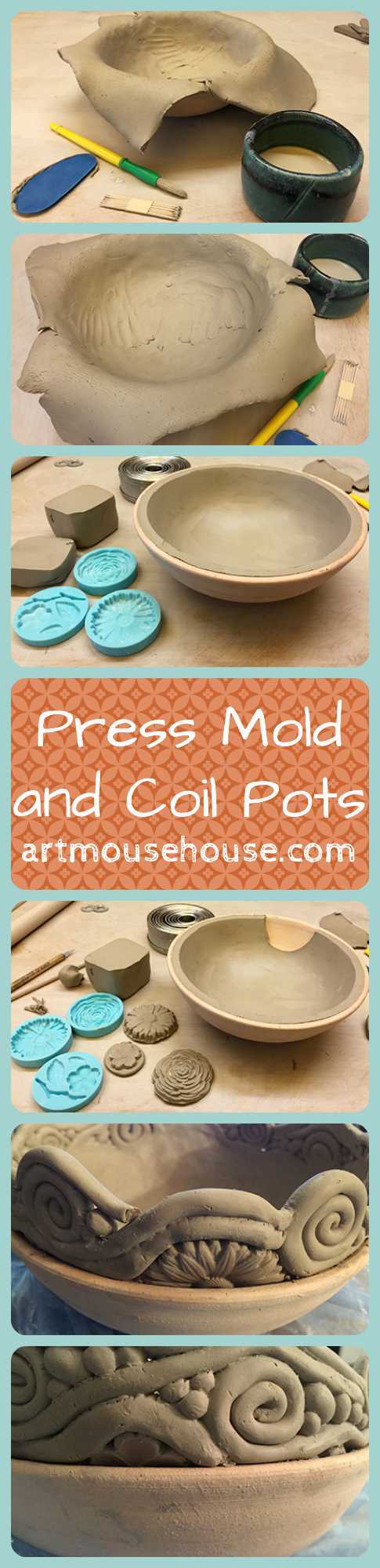

- Press molding: Press molding is a technique where clay is pressed into a mold to create consistent shapes. It is often used for making pottery pieces with intricate designs.

Firing and Glazing

After the pottery is shaped, it needs to be fired in a kiln to harden the clay and make it permanent. Firing temperature and duration depend on the type of clay used. Once the pottery is fired, glazes can be applied to add color and surface finishes. Glazes can be applied by dipping, brushing, or spraying.

Conclusion

Clay is a fundamental material in the art of pottery making. Its malleability, when wet, and durability, when fired, make it suitable for creating functional and decorative pottery pieces. Whether handbuilding, wheel throwing, or using press molds, clay offers endless possibilities for artistic expression.

Press Mold

A press mold is a tool used in pottery making to create consistent and repeatable shapes. It is made of a rigid material, such as plaster or wood, and has a cavity with the desired shape. The clay is pressed into the mold, taking on its shape, and can be easily released by flexing or tapping the mold. Press molds are especially useful for creating symmetrical and intricate designs.

Advantages of using a press mold:

- Consistency: Press molds allow potters to create multiple items with the same shape and size, ensuring uniformity in their designs.

- Efficiency: By using a press mold, potters can save time and effort by quickly creating multiple pieces in a short period.

- Precision: The use of a press mold ensures accurate and precise shapes, especially for intricate designs that are difficult to achieve by hand.

- Repeatability: Since press molds create consistent shapes, potters can easily reproduce their designs to meet customer demands.

- Versatility: Press molds can be used for various pottery techniques, including slab construction, coil building, and even slip casting.

The process of using a press mold:

- Prepare the clay: Knead the clay until it is soft and pliable. Remove any air bubbles to ensure an even distribution inside the mold.

- Coat the mold: Apply a thin layer of a release agent, such as cornstarch or talc, to the inside of the mold to prevent the clay from sticking.

- Press the clay: Take a ball of clay and press it firmly into the mold, making sure to fill all the cavities and corners.

- Trim excess clay: Use a knife or a modeling tool to remove any excess clay from the edges of the mold. This step helps create clean and smooth edges.

- Release the clay: Flex or tap the mold gently to release the clay. If needed, use a wooden or rubber mallet to ease the clay out of the mold.

- Refine the shape: Use your fingers or pottery tools to refine the shape of the pressed clay, if necessary, to achieve the desired look.

- Let it dry: Allow the pressed clay to dry completely before further handling or decoration. This may take a few days or more depending on the thickness of the clay.

- Repeat the process: If desired, repeat the process with the same mold to create additional pieces.

Tips for using a press mold:

- Experiment with different clays: Different types of clay have varying levels of plasticity, which can affect the ease of pressing into the mold.

- Avoid overfilling the mold: Pressing too much clay into the mold may lead to distortion or cracking when removing the piece.

- Clean the mold after use: Remove any remaining clay or debris from the mold to ensure it stays in good condition for future use.

- Consider adding texture: To add visual interest to the pressed pieces, you can use texture tools or stamps on the clay before pressing it into the mold.

- Experiment with release agents: Different release agents may work better for specific clay types or mold materials, so try out different options to find what works best for you.

With a press mold, potters can easily create consistent and intricate shapes, expanding their creative possibilities and saving time in the pottery-making process.

Rolling Pin

A rolling pin is a cylindrical kitchen tool used to flatten and shape dough. It is a versatile tool that can also be used in pottery making to flatten clay and create uniform thickness. Here are the steps to use a rolling pin in pottery making:

- Prepare your workspace: Make sure you have a clean and flat surface to work on. Dust it lightly with cornstarch or clay to prevent the clay from sticking to the surface.

- Prepare your clay: Take a small piece of clay and shape it into a round ball. This will make it easier to work with.

- Flatten the clay: Place the clay ball on your workspace and lightly press it down with your hand to create a flat surface. This will make it easier to roll out the clay evenly.

- Begin rolling: Take your rolling pin and place it at one end of the clay. Apply gentle pressure and roll the pin away from you, moving across the clay. Continue rolling until you reach the other end of the clay.

- Rotate and roll again: Rotate the clay 90 degrees and repeat the rolling process. This helps ensure that the clay is rolled out evenly and prevents it from sticking to the surface.

- Check the thickness: Periodically check the thickness of the clay by placing a ruler or clay gauge next to it. Aim for a consistent thickness throughout.

- Trim the edges: Once you have achieved the desired thickness, use a sharp knife or pottery tool to trim any uneven or excess clay from the edges.

- Use the rolled clay: Once the clay is rolled and trimmed, it is ready to be used in your pottery project. You can now transfer it to a press mold or use it to hand-build your desired shape.

Using a rolling pin in pottery making can help you create uniform pieces and achieve the desired thickness. It is a simple and effective tool that can be used by beginners and experienced potters alike.

Step 2: Preparing the Clay

Before using the press mold, it is important to prepare the clay properly. This involves ensuring that the clay is soft and workable, free from any air bubbles or impurities, and ready to be shaped into the desired form.

Follow these steps to prepare the clay:

- Gather the clay: Start by gathering the clay that you want to use. Use a clay body that is suitable for press molding, ensuring that it has a good plasticity and is easy to work with.

- Condition the clay: Next, condition the clay by kneading it. This helps to make the clay more homogenous and removes any air pockets that may be present. Knead the clay with your hands until it becomes soft and pliable.

- Remove impurities: Check the clay for any impurities or foreign objects. Remove any stones, twigs, or other debris that may have gotten into the clay.

- Add water if necessary: If the clay feels dry or stiff, you may need to add a small amount of water to it. Sprinkle a little water onto the clay and knead it again until it reaches the desired consistency. Be careful not to add too much water, as this can make the clay too wet and difficult to work with.

- Optional: mix different clay bodies: If desired, you can also mix different clay bodies together to create unique effects or variations in color and texture. Knead the different clays together until they are well combined.

By properly preparing the clay, you ensure that it is ready to be pressed into the mold and will result in a successful pottery piece. Once the clay is prepared, you can move on to the next step of the process.

Kneading

Kneading is an essential step in preparing clay for use with a press mold. This process helps to remove any air pockets and inconsistencies in the clay, resulting in a more uniform and malleable material.

To begin, place the clay on a clean and flat surface. It is important to keep the surface dust-free to prevent any unwanted debris from getting mixed into the clay.

1. Flatten the Clay

Using the palms of your hands, press down on the clay to flatten it into a thick disc. This step helps to create an even starting point for kneading.

2. Cut and Stack

Take a wire cutter or a sharp knife and cut the flattened clay into smaller sections. This makes it easier to knead and work with.

Stack the cut sections on top of each other, creating layers of clay. This step helps to evenly distribute any moisture that may be in the clay.

3. Push and Fold

Begin the kneading process by pushing the top layer of clay away from you using the heel of your hand. Apply pressure evenly and firmly to ensure that the clay is properly compressed.

Next, fold the clay over itself and push it away from you once again. Repeat this process of pushing and folding until the clay becomes more pliable and consistent in texture.

4. Rotate and Repeat

After each push and fold, rotate the clay a quarter-turn. This helps to ensure that all sides of the clay are equally worked and prevents it from developing any weak spots.

Continue to repeat the pushing, folding, and rotating process until the clay is smooth, elastic, and free of any air bubbles.

5. Test the Consistency

To check if the clay is properly kneaded, perform a simple test. Pinch off a small piece of clay and roll it into a ball. If the clay holds together without cracking or crumbling, it is ready for use.

Once the clay has been kneaded to the desired consistency, it is ready to be used with a press mold. Remember to cover the clay with a damp cloth or plastic wrap to prevent it from drying out while you work on your project.

Rolling

Rolling is a common technique used with press molds to create pottery shapes. It involves placing a ball of clay onto a flat surface and then using a rolling pin to flatten and shape the clay.

To start rolling, prepare a workspace by cleaning and dusting off the surface. This will help prevent any debris from getting stuck on the clay. It’s also a good idea to lightly coat the surface with cornstarch or water to prevent the clay from sticking.

Take a small ball of clay, slightly larger than the size of the mold cavity. Place the ball of clay onto the prepared surface and flatten it slightly with your hands to create a disc shape.

Using a rolling pin, begin rolling the clay outwards from the center in all directions. Apply even pressure and roll the clay back and forth until it is about 1/4 inch thick. Make sure to check the thickness of the clay with a thickness gauge or ruler to ensure consistency.

Rotate the clay occasionally as you roll to maintain an even thickness and prevent it from sticking to the surface. If the clay starts to stick, lightly dust the surface with more cornstarch or water as needed.

Once the clay is rolled out to the desired thickness, carefully lift it from the surface and place it onto the mold. Gently press the clay into the mold cavity, ensuring that it is in full contact with all the details of the mold.

Trim away any excess clay from the edges of the mold using a sharp knife or clay cutting tool. Smooth out any imperfections or seams with your fingers, a rib tool, or a sponge.

After the clay has been pressed into the mold, allow it to dry and harden for the recommended amount of time before removing it from the mold.

Once the clay has dried, carefully remove the molded piece from the mold. If necessary, use a soft brush or sandpaper to smooth out any rough edges or areas.

Rolling is a versatile technique that can be used with a variety of press molds to create unique pottery shapes. Experiment with different clay types, thicknesses, and pressure to achieve the desired results.

Step 3: Pressing the Clay

Once your clay slab is prepared, it’s time to begin the pressing process. Follow these steps to successfully press the clay into the mold:

- Place the clay slab on top of the mold, ensuring that it covers the entire surface evenly.

- Use your hands or a rolling pin to gently press the clay down onto the mold, starting from the center and working your way outwards. Apply even pressure to prevent any air bubbles or unevenness.

- Continue pressing the clay until it reaches the desired thickness. This will vary depending on the type of piece you are making and the specific instructions for your mold. Use a ruler or calipers to measure the thickness as you go.

- If the clay slab extends beyond the edges of the mold, carefully trim away the excess using a sharp knife or clay trimming tool.

- Once the clay is pressed and trimmed, smooth out any rough edges or imperfections using a sponge or your fingers. Pay attention to the edges and corners, ensuring they are clean and smooth.

Remember to work slowly and carefully during the pressing process to achieve the best results. Take breaks if needed to avoid any mistakes or frustration. Once you are satisfied with the pressed clay, you are ready to move on to the next step, which is removing the clay from the mold.

Placing the Mold

Once you have prepared your clay and press mold, it’s time to start making pottery! Follow these steps to properly place the mold:

- Prepare your workspace: Ensure you have a clean and clutter-free area to work in. This will help prevent any accidents or damage to your pottery.

- Position the mold: Place the press mold on a flat surface, such as a table or workbench. Make sure the mold is stable and won’t move during the process.

- Prepare the clay: Take a clay ball and cut it into manageable pieces. Knead each piece to soften it and remove any air bubbles. Set aside the prepared clay for the next step.

- Fill the mold: Take one of the prepared clay pieces and press it firmly into the mold. The clay should cover the entire mold cavity and be pressed down evenly.

- Remove excess clay: Use a trimming tool or your fingers to remove any excess clay from the edges of the mold. This will help create a clean and smooth pottery piece.

- Release the pottery: Carefully lift the mold to release the pottery piece. Gently tap the mold if needed to loosen the pottery from the mold.

- Inspect and refine: Examine the pottery piece for any imperfections or rough edges. Use tools like a rib or sponge to refine and smooth the surface as desired.

Repeat these steps for each pottery piece you want to create using the press mold. With practice, you’ll become more familiar with the molding process and can experiment with different clay types, shapes, and designs.

FAQ:

What is a press mold and how does it work?

A press mold is a tool used in pottery to create consistent and repeated shapes. It is a mold made from plaster or another material, with a cavity in the shape of the desired object. To use a press mold, clay is pressed into the cavity, and excess clay is trimmed away. The mold is then opened, and the clay object is carefully removed.

Are there different types of press molds available?

Yes, there are various types of press molds available for pottery. Some common types include hump molds, slump molds, and sprig molds. Hump molds are used to create convex shapes, such as bowls or plates. Slump molds create concave shapes, such as dishes or vases. Sprig molds are used to add decorative elements to pottery, by pressing clay onto the mold and attaching it to a different clay object.

What materials can be used to make a press mold?

Press molds can be made from various materials, depending on the desired effect and durability. Plaster is a popular choice as it absorbs moisture from the clay and helps with the drying process. Other materials like wood, bisque-fired clay, or even silicone can also be used to make press molds.

Can I make my own press mold?

Yes, you can make your own press mold for pottery. To create a press mold, start by making a positive shape out of clay or another material. Once the positive shape is created, a negative mold can be made by pouring plaster over the positive shape and allowing it to dry. Once the plaster is fully dry, the press mold is ready to be used.