Silk is a luxurious fabric that has been prized for centuries for its smooth texture and lustrous appearance. When it comes to the production of silk fabrics, there are two main techniques: weaving and knitting. Understanding the differences between silk weaving and silk knitting can help one appreciate the intricate process of creating silk fabrics and the unique qualities they possess.

Silk weaving is the traditional method of fabric production that involves interlacing two sets of yarns, called warp and weft, to create a stable and durable fabric. The warp yarns are stretched vertically on a loom, while the weft yarns are woven horizontally across the warp. This interlacing creates a tightly woven fabric that is known for its strength and resilience. Silk woven fabrics have a distinct pattern or design that is created by the arrangement of the warp and weft yarns.

Silk knitting, on the other hand, involves the use of needles or machines to create loops of yarn that are interlocked to form a fabric. Unlike weaving, knitting does not involve the interlacing of yarns, but rather the creation of loops that give the fabric its characteristic stretch and elasticity. Silk knitted fabrics are known for their softness, drape, and ability to conform to the body. They are often used for garments such as sweaters, socks, and lingerie.

Both silk weaving and silk knitting have their own unique characteristics and applications. While silk woven fabrics are more structured and durable, silk knitted fabrics are softer and more flexible. The choice between the two depends on the desired outcome and purpose of the fabric. Whichever method is used, the production of silk fabrics requires skill, precision, and a deep appreciation for the beauty and versatility of silk.

Is Silk Woven or Knit?

Silk can be both woven and knit, depending on the desired end result and the type of fabric being produced. The process of weaving and knitting silk involves different techniques and equipment, each resulting in a distinct type of fabric.

Weaving Silk:

Weaving silk involves interlacing the threads of the silk yarn at right angles to create a stable fabric. This is done on a loom, which holds the vertical warp threads under tension while the horizontal weft threads are woven through them. The process of weaving creates a tightly woven fabric with a consistent structure. Silk fabrics woven in this manner include satin, charmeuse, and organza.

Knitting Silk:

Knitting silk involves creating a fabric by interlocking loops of silk yarn using knitting needles or a knitting machine. This results in a more flexible and stretchy fabric compared to woven silk. Knitted silk fabrics include jersey, rib, and interlock knits.

Differences Between Woven and Knit Silk Fabrics:

- Structure: Woven silk has a more stable and structured feel, while knit silk has more stretch and drape.

- Strength: Woven silk is generally stronger and more durable than knit silk.

- Appearance: Woven silk often has a smooth, shiny surface, while knit silk can have a textured or ribbed appearance.

- Breathability: Knit silk tends to be more breathable and lightweight compared to woven silk.

- Uses: Woven silk is commonly used for formal dresses, bridal gowns, and upholstery, while knit silk is often used for silk underwear, loungewear, and stretchy apparel.

In conclusion, while silk can be woven or knit, the choice between the two depends on the desired characteristics and applications of the fabric. Whether you prefer the structured elegance of woven silk or the stretchy comfort of knit silk, both types offer unique qualities and bring the luxurious feel of silk to different types of garments and products.

Understanding the Difference Between Silk Weaving and Silk Knitting

Silk is a luxurious and highly sought-after fabric that has been used for centuries. It is known for its softness, strength, and beautiful luster. Silk can be created through two different processes: weaving and knitting. While both techniques produce silk fabric, there are some key differences between silk weaving and silk knitting.

Silk Weaving:

- Silk weaving is the process of interlacing silk threads lengthwise (warp) and widthwise (weft) to create a fabric.

- It involves the use of a loom, which can either be manual or mechanized.

- The warp threads are stretched vertically on the loom, while the weft threads are woven horizontally across the warp.

- The weaving process allows for the creation of intricate patterns and designs on the fabric.

- Silk weaving produces a fabric with a strong structure and a slightly stiff drape.

Silk Knitting:

- Silk knitting involves the use of knitting needles or knitting machines to create fabric.

- It utilizes a series of interlocking loops of silk yarn to form the fabric.

- Knitted silk fabric is stretchy and flexible, with a drape that molds to the body.

- Knitting allows for the creation of different textures, such as ribbing or lace patterns.

- Knitted silk fabric tends to have a smoother and more fluid appearance compared to woven silk fabric.

In summary, silk weaving and silk knitting are two distinct processes for creating silk fabric. Silk weaving involves interlacing warp and weft threads on a loom, while silk knitting uses knitting needles or machines to create interlocking loops of silk yarn. The resulting fabrics have different characteristics in terms of structure, drape, and appearance. Whether you choose weaving or knitting, silk fabric is a luxurious choice that adds elegance to any garment or textile.

Exploring the Traditional Craft of Silk Production

Silk production is an ancient craft that has been practiced for thousands of years. The process of creating silk involves several distinct steps, each requiring skill and precision.

Cultivating Silkworms: The first step in silk production is the cultivation of silkworms. Silkworms are hatched from eggs and are fed a diet of mulberry leaves. Over a period of about 25-30 days, the silkworms grow and molt several times until they are ready to spin their cocoons.

Harvesting Cocoons: Once the silkworms have formed their cocoons, the cocoons are carefully harvested. The cocoons are made of a single thread of silk that is approximately 900-1500 meters long. To obtain this thread, the cocoons are boiled in hot water, which kills the silkworm inside and loosens the thread.

Reeling Silk: After the cocoons have been boiled, the silk thread is reeled. This is done by carefully unraveling the silk thread from the cocoon and winding it onto a reel. The reeling process must be done with precision to ensure that the silk thread remains intact and undamaged.

Spinning and Weaving: Once the silk thread has been reeled, it can be spun into yarn and then woven into fabric. Different methods of spinning and weaving can be used to create different types of silk fabric, such as satin or chiffon. Each method requires specialized knowledge and skill.

Dyeing: After the silk fabric has been woven, it can be dyed to give it color. Silk has excellent dye absorption properties, which allows for rich and vibrant colors to be achieved. Dyeing can be done using natural or synthetic dyes, depending on the desired result.

Finishing: The final step in silk production is the finishing process. This involves treating the silk fabric to enhance its appearance and texture. Common finishing processes include steaming, washing, and pressing. These processes help to remove any remaining impurities and give the fabric a smooth and lustrous finish.

| Step | Description |

|---|---|

| Cultivating Silkworms | Hatching silkworm eggs and feeding them a diet of mulberry leaves. |

| Harvesting Cocoons | Collecting the cocoons after the silkworms have formed them. |

| Reeling Silk | Unraveling the silk thread from the cocoons and winding it onto a reel. |

| Spinning and Weaving | Turning the silk thread into yarn and weaving it into fabric. |

| Dyeing | Coloring the silk fabric with natural or synthetic dyes. |

| Finishing | Treating the silk fabric to enhance its appearance and texture. |

Overall, silk production is a meticulous and time-consuming process that requires both technical expertise and artisanal skill. The resulting silk fabric is highly valued for its luxurious feel, beautiful sheen, and delicate drape, making it a prized material in the world of fashion and design.

Silk Weaving: A Fine Art

Silk weaving is a centuries-old craft that has been perfected over time. It is not only a technical skill but also an art form that requires precision, creativity, and patience. The process of silk weaving involves interlacing silk threads to create a delicate and luxurious fabric that is highly prized for its beauty and texture.

One of the key characteristics of silk weaving is the use of a loom, a device that holds the warp threads in place while the weaver manipulates the weft threads to create the desired pattern. The loom can be either hand-operated or mechanized, depending on the complexity of the design and the skill of the weaver. Hand-operated looms are often preferred for their ability to produce intricate designs and unique textures.

The silk used for weaving is typically derived from the cocoons of silk worms. These cocoons are carefully unraveled to extract the silk filament, which is then spun into threads. The threads are then dyed and wound onto bobbins, ready to be woven into fabric. The weaver selects the desired pattern and begins the weaving process, carefully manipulating the thread to create the desired design and texture.

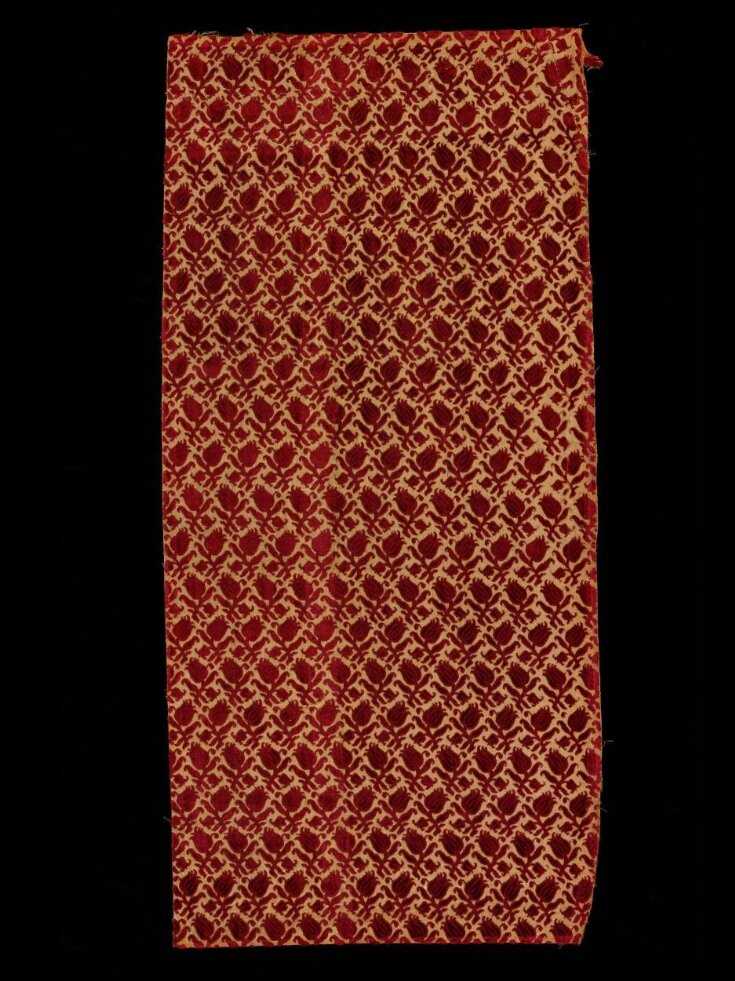

Silk weaving can produce a wide range of fabrics, from lightweight and smooth silk chiffon to heavier and more structured silk brocade. The choice of fabric depends on the desired end-use and the preferences of the weaver. In addition to fabric, silk weaving can also be used to create other decorative items such as scarves, shawls, and tapestries.

One of the unique aspects of silk weaving is its ability to combine tradition with innovation. While the techniques and tools used in silk weaving have remained largely unchanged over the centuries, weavers continue to experiment with new colors, patterns, and textures to create contemporary and unique designs. This constant evolution keeps silk weaving relevant and adaptable to changing tastes and trends.

In conclusion, silk weaving is a fine art that combines technical skill, creativity, and tradition. It produces fabrics that are not only luxurious to the touch but also visually stunning. Whether used in fashion, interior design, or art, silk weaving continues to captivate and inspire with its timeless beauty.

Examining the Intricate Process of Silk Weaving

Silk weaving is a time-honored technique used to create beautiful and luxurious silk fabrics. The process involves several intricate steps, each requiring precision and skill. Let’s take a closer look at how silk is woven.

- Cocoon Harvesting: The first step in silk weaving is harvesting the cocoons. Silk threads are obtained from the cocoons of silkworms, which are carefully cultivated and fed a diet of mulberry leaves to produce high-quality silk.

- Unreeling the Silk: Once the cocoons are harvested, they are soaked in hot water to loosen the sericin, a natural gum that holds the silk fibers together. The silk fibers are then carefully unraveled from the cocoons, a process known as unreeling.

- Thread Spinning: After unreeling, the silk threads are spun together to create a single, continuous thread. This process involves twisting the individual silk fibers together, usually with the help of a spinning wheel or machine.

- Preparing the Loom: The next step is setting up the loom, a device used to hold the warp threads in place during weaving. The warp threads are carefully wound onto the loom, creating a parallel arrangement of threads stretched lengthwise.

- Weaving: With the loom prepared, the silk weaving process can begin. The weaver carefully passes the weft thread, which runs perpendicular to the warp, through the warp threads, creating the fabric’s structure. This is typically done by hand, using a shuttle or a loom attachment.

- Finishing: Once the weaving is complete, the fabric goes through a series of finishing processes. These may include washing, dyeing, and any necessary treatments or embellishments to enhance the fabric’s appearance and texture.

- Final Inspection: Before the silk fabric is deemed ready for use, it undergoes a final inspection to ensure quality and consistency. Any imperfections are addressed, and the fabric is carefully examined to meet the desired standards.

As you can see, silk weaving is a labor-intensive and meticulous process that requires a high level of craftsmanship. The result is a luxurious fabric admired for its softness, sheen, and durability.

Silk Knitting: A Modern Approach

Silk knitting is a technique that has gained popularity in recent years due to its versatility and unique characteristics. Unlike traditional silk weaving, which involves creating a fabric by interlacing warp and weft threads, silk knitting is a process of interlocking loops of yarn to create a textile. This technique allows for greater flexibility in design and is often used to create delicate and intricate lace patterns.

One of the main advantages of silk knitting is its ability to create fabrics with a considerable amount of stretch and drape. This makes it ideal for creating garments that require a close fit or have fluidity and movement. Silk knitted fabrics are also known for their breathable properties, which make them comfortable to wear in warmer climates.

Another benefit of silk knitting is its ability to showcase the natural sheen and luster of silk fibers. The interlocking loops of yarn create a surface that reflects light, giving the fabric a luxurious appearance. This makes silk knitting a popular choice for creating high-end fashion pieces and accessories.

Modern advancements in technology have made silk knitting more accessible to both designers and hobbyists. Knitting machines equipped with silk-specific needles and yarn feeders allow for faster production of silk knitted fabrics. Additionally, the availability of silk yarn in a wide range of colors and textures has expanded the possibilities for creative expression in silk knitting.

In conclusion, silk knitting offers a modern approach to creating silk textiles with stretch, drape, and a luxurious appearance. Its versatility and adaptability make it a popular choice for designers looking to create unique and fashionable garments and accessories. With the help of technology and an array of silk yarn options, silk knitting has become more accessible and provides endless opportunities for creativity.

Discovering the Contemporary Technique of Silk Knitting

The art of silk knitting is a modern technique that has gained popularity in recent years. It offers a unique and versatile way of working with silk, allowing for a range of stunning creations that can’t be achieved through traditional weaving methods.

Unlike silk weaving, which involves the interlacing of warp and weft threads on a loom, silk knitting utilizes specialized machines to create intricate patterns and textures.

Process of Silk Knitting:

- Design: The process begins with the design phase, where the desired pattern and texture are planned. This can be done through computer-aided design (CAD) software or by hand.

- Yarn Selection: Next, a suitable silk yarn is chosen. Silk knitting can be done using various types of silk yarn, including spun silk, raw silk, or even silk blends.

- Machine Setup: The silk yarn is then loaded onto a knitting machine. The machine is set up according to the desired stitch pattern, stitch size, and tension.

- Knitting: The machine starts the knitting process, creating loops and interlocking them to form the fabric. The operator monitors the machine’s progress and ensures the smooth operation of the process.

- Finishing: Once the fabric is knitted, it undergoes various finishing processes, such as washing, steaming, and blocking. These processes enhance the silk’s luster, drape, and softness.

- Final Touches: The knitted silk fabric can then be cut, sewn, and shaped into various garment or accessory designs, such as dresses, scarves, or shawls.

- Decoration: Embellishments, such as embroidery, beading, or prints, can be added to enhance the final product.

Advantages of Silk Knitting:

- Flexibility: Silk knitting allows for the creation of fabrics with different degrees of stretch, making them suitable for various applications.

- Texture Variety: The knitting process can produce fabrics with a wide range of textures, from delicate laces to chunky ribbed knits.

- Efficiency: Silk knitting machines can produce fabrics at a faster rate compared to traditional hand weaving methods, making it a more efficient production technique.

- Design Freedom: The versatility of silk knitting enables designers to experiment with complex patterns and unique designs that may not be feasible with other silk production techniques.

- Softness: Silk knitting creates fabrics that are soft and lightweight, offering a luxurious feel.

Overall, the contemporary technique of silk knitting opens up a world of creative possibilities for designers and artisans. Its unique qualities and advantages make it a popular choice for creating luxurious and distinctive silk products.

Comparing Silk Weaving and Silk Knitting

Silk Weaving:

- Silk weaving is a process that involves interlacing silk threads in a specific pattern to create a fabric.

- It is a traditional method of producing silk fabric and has been practiced for centuries.

- Weaving requires a loom, which is a device used to hold the threads in place and facilitate the interlacing process.

- The process involves weaving the weft threads (horizontal threads) over and under the warp threads (vertical threads) to create the desired pattern.

- Silk weaving allows for the creation of intricate patterns and designs, as well as varying textures and thicknesses of fabric.

Silk Knitting:

- Silk knitting is a process that involves creating fabric by interlocking loops of silk yarn using knitting needles or a knitting machine.

- It is a more modern method of producing silk fabric and is often used for creating lightweight and stretchy fabrics.

- Knitting allows for the creation of fabrics with different stitch patterns, such as garter stitch, stockinette stitch, or rib stitch.

- Knitted silk fabrics are known for their breathability, drape, and elasticity.

- Knitting can be done by hand or by machine, with machine knitting allowing for faster production.

Comparison:

| Aspect | Silk Weaving | Silk Knitting |

|---|---|---|

| Process | Interlacing silk threads in a specific pattern using a loom | Interlocking loops of silk yarn using knitting needles or a knitting machine |

| Tools/Equipment | Loom | Knitting needles or knitting machine |

| Resulting Fabric | Intricate patterns and designs, varying textures and thicknesses | Lightweight, stretchy, breathable, drapey |

| Tradition | Centuries-old method | More modern method |

| Production Speed | Slower | Faster (especially with knitting machines) |

In conclusion, silk weaving and silk knitting are two different methods of creating silk fabric. Weaving involves interlacing silk threads on a loom to create intricate patterns and designs, while knitting involves interlocking loops of silk yarn to create lightweight and stretchy fabrics. Each method has its own unique characteristics and is used for different purposes in the world of silk production.

Highlighting the Distinctions Between the Two Methods

There are several key differences between silk weaving and silk knitting. These distinctions not only affect the final appearance of the fabric but also impact the production process and the properties of the silk.

-

Weaving: Silk weaving involves interlacing the warp (lengthwise) and weft (crosswise) threads to create a fabric structure. The warp threads are held taut on the loom, while the weft threads are threaded through the warp using a shuttle or other weaving tool. This method produces a flat, tightly woven fabric with distinct patterns and designs.

-

Knitting: Silk knitting, on the other hand, involves interlocking loops of silk yarn to create a fabric. Knitting can be done by hand or by machine. This method produces a more stretchy and flexible fabric compared to weaving. Knitted silk fabrics often have a more textured appearance and are commonly used for garments that require a greater degree of elasticity.

-

Structure: While both weaving and knitting create fabrics, the structure of the resulting fabric is different. Woven silk has clear, well-defined patterns and designs due to the interlacing of the warp and weft threads. Knitted silk, on the other hand, has a more fluid and drapey structure with a greater tendency to stretch and conform to the body.

-

Production: Weaving silk is typically done on a loom, which requires setting up the warp threads and then manually interlacing the weft threads. It is a slower and more labor-intensive process compared to knitting. Knitting silk can be done by hand, using knitting needles, or by machine, which allows for faster and more efficient production.

-

End use: The differences in structure and properties make woven and knitted silk suitable for different end uses. Woven silk fabrics are commonly used for formal and structured garments, such as suits, dresses, and upholstery. Knitted silk fabrics, on the other hand, are often used for more casual and comfortable garments, such as t-shirts, sweaters, and lingerie.

Overall, while both silk weaving and silk knitting are methods of creating silk fabrics, they result in fabrics with distinct characteristics and are suited for different purposes. Understanding these differences can help individuals choose the right type of silk fabric for their specific needs and preferences.

Applications of Silk Weaving

Silk weaving, one of the oldest textile techniques, has many applications across various industries. The unique properties of silk, such as its strength, luster, and breathability, make it a sought-after material for a wide range of products.

Fashion and Clothing:

- Silk is commonly used in the production of high-end fashion garments, such as dresses, blouses, and evening gowns. Its luxurious feel and shimmering appearance make it a favorite choice among fashion designers.

- Silk scarves and ties are also popular accessories that showcase the beauty of silk weaving.

Home Textiles:

- Silk fabrics are used to create luxurious bedding sets, including sheets, pillowcases, and duvet covers. Their smooth texture and natural temperature-regulating properties provide a comfortable night’s sleep.

- Decorative items like curtains, drapes, and upholstery made from silk fabrics add elegance and sophistication to any interior design.

Traditional Crafts:

- In many cultures, silk weaving is an integral part of traditional crafts. For example, silk is used to create intricate tapestries, wall hangings, and traditional costumes in countries like China, India, and Japan.

- Embroidery and silk threadwork are also popular crafts that utilize silk weaving techniques.

Industrial Applications:

- Silk fibers are used in the production of high-quality parachutes and ropes due to their strength and durability.

- Silk fabrics can also be used as filters for various industries, including air purification and water filtration.

Medical and Cosmetics:

- Silk is used in the production of medical textiles, such as sutures and dressings, due to its biocompatibility and antimicrobial properties.

- Silk proteins are also used in cosmetic products, like moisturizers and hair care products, for their nourishing and conditioning effects.

These are just a few examples of the wide range of applications of silk weaving. The versatility and beauty of silk make it a valuable material in many industries, combining tradition with innovation.

FAQ:

Is silk woven or knit?

Silk is primarily woven, not knit. It is a natural fiber that is commonly woven into luxurious fabrics.

What is the main difference between silk weaving and silk knitting?

The main difference between silk weaving and silk knitting is the way the fabric is constructed. Weaving involves interlacing the warp (longitudinal) and weft (horizontal) threads, while knitting involves interlocking loops of yarn.

Why is silk primarily woven?

Silk is primarily woven because it is a strong and durable fiber that lends itself well to the weaving process. The interlacing of warp and weft threads creates a stable fabric with a smooth and lustrous surface.

Can silk be knit?

While silk is primarily woven, it can also be knit. Knitting silk creates a different fabric with a stretchier and more flexible texture compared to woven silk. Knitted silk garments are often used for lightweight and comfortable clothing.

What are some common applications of woven silk?

Woven silk is commonly used for various applications, including clothing such as dresses, blouses, and skirts, as well as home decor items like curtains, upholstery, and beddings. Its smooth and luxurious texture makes it a popular choice for high-end products.

Can you provide examples of knitted silk products?

Some examples of knitted silk products include silk scarves, silk socks, and silk underwear. The stretchiness of knitted silk makes it suitable for items that require a closer fit and greater flexibility.