Properly drying wood is an essential step in woodworking. Whether you’re a beginner or an experienced woodworker, understanding how to properly dry wood will help prevent warping, splitting, and other issues that can result from working with wet or improperly dried wood. In this comprehensive guide, we will take you through the steps and techniques for drying wood effectively.

Step 1: Choosing the right wood

Not all types of wood are suitable for drying and using in woodworking projects. Some woods are more prone to warping and splitting than others. It’s important to choose wood species that are known for their stability and resistance to moisture. Examples of such woods include oak, maple, and birch. Additionally, it’s best to select wood that has been properly kiln-dried or air-dried before purchasing.

Step 2: Initial moisture testing

Before you begin the drying process, it’s important to measure the moisture content of the wood. This can be done using a moisture meter or by weighing the wood before and after drying. Ideally, the moisture content should be around 6-8% for indoor woodworking projects. If the wood has a higher moisture content, it will need to be dried further.

Tip: It’s best to leave the ends of the boards uncovered to allow for better air circulation during the drying process.

Step 3: Air drying

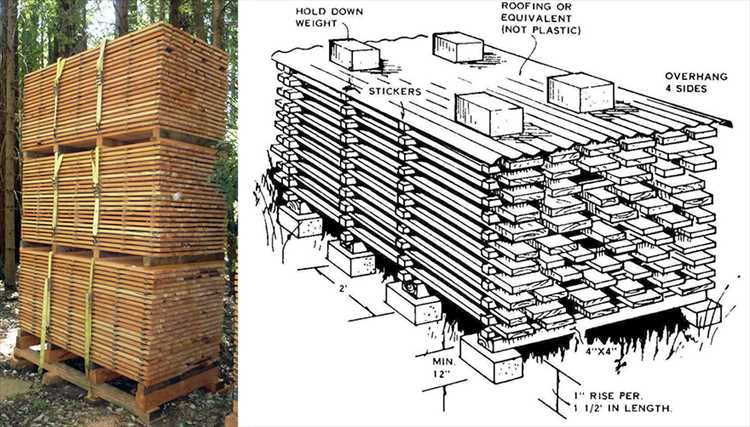

Air drying is the most common method for drying wood. It involves stacking the lumber in a well-ventilated area and allowing it to dry naturally over time. To ensure proper air circulation, the lumber should be stacked with spacers between the boards. It’s important to monitor the moisture content regularly during the drying process and adjust the stacking as necessary.

Step 4: Kiln drying

If you need to expedite the drying process or if the wood has a higher moisture content, kiln drying can be used. Kiln drying involves placing the wood in a specially designed kiln where temperature and humidity can be controlled. This method allows for quicker and more precise drying, but it can also be more expensive.

By following these steps and techniques, you can ensure that the wood you use for your woodworking projects is properly dried and ready for use. Properly dried wood not only helps prevent issues during the woodworking process but also ensures the longevity and quality of the finished product.

Why Proper Drying of Wood is Essential for Woodworking

Properly drying wood is an essential step in woodworking that cannot be overlooked. The process of drying wood involves removing moisture from the wood to stabilize it and prevent future issues. Whether you are a professional woodworker or a hobbyist, understanding why proper wood drying is important will significantly impact the quality and longevity of your woodworking projects.

Preventing Warping and Shrinkage:

Wood naturally contains moisture, and if not adequately dried, it can result in warping and shrinkage. Warping occurs when the wood dries unevenly, causing it to bend or twist. Shrinkage, on the other hand, happens when the wood loses moisture and contracts, resulting in cracks and gaps. Properly dried wood will significantly minimize the risk of warping and shrinking, ultimately ensuring the structural integrity and aesthetics of your woodworking projects.

Minimizing Mold and Fungi Growth:

Moisture in wood creates a perfect environment for mold and fungi to grow. These microorganisms not only compromise the appearance of the wood but also pose health risks to individuals working with the wood. Properly drying the wood will prevent the growth of mold and fungi, ensuring a safe and healthy working environment.

Reducing Post-Construction Issues:

When wood is not properly dried before using it in woodworking projects, it can cause post-construction issues such as splitting, warping, and cracking. These issues can significantly affect the durability and appearance of the finished product. By drying the wood properly beforehand, you can minimize the risk of these post-construction issues and ensure that your woodworking projects stand the test of time.

Improved Workability:

Drying wood properly not only helps prevent issues but also improves its workability. Properly dried wood is easier to cut, shape, and join, making it more manageable for woodworking projects. It allows for smoother cuts, reduces tear-out, and improves the overall precision and quality of the woodworking process.

In conclusion, proper drying of wood is essential for woodworking due to its impact on preventing warping and shrinkage, minimizing mold and fungi growth, reducing post-construction issues, and improving workability. By taking the time to dry your wood properly before using it in your woodworking projects, you can ensure the best possible results and create long-lasting, beautiful pieces.

Understanding Wood Drying: The Basics

Wood drying is a critical process in woodworking that involves removing moisture from wood to make it stronger, more stable, and suitable for various woodworking projects. Understanding the basics of wood drying is essential for every woodworker to ensure the quality and longevity of their creations.

The Importance of Wood Drying

Wood is a hygroscopic material, meaning it easily absorbs and releases moisture from its surroundings. Freshly cut or sawn wood contains a significant amount of water, typically referred to as “green” or “wet” wood. Green wood is not ideal for woodworking projects as it is prone to warping, shrinking, and cracking as it dries.

By properly drying wood, woodworkers can stabilize the material, reduce its moisture content, and minimize the risks of distortion or damage during the woodworking process. Dry wood is not only easier to work with but also enhances the strength, durability, and overall quality of the finished product.

The Drying Process

The process of drying wood involves removing moisture from the wood fibers until it reaches its equilibrium moisture content (EMC). EMC is the point at which wood neither gains nor loses moisture from its surroundings.

There are two primary methods for drying wood: air drying and kiln drying.

Air Drying:

- Common method for drying wood, especially for small-scale woodworkers.

- Involves stacking the wood in a well-ventilated area, protecting it from direct sunlight and rain.

- Air drying can take several months to years, depending on the wood species, thickness, and environmental conditions.

- Slow drying can result in less stress buildup in the wood and may provide better stability and quality.

Kiln Drying:

- A more controlled and efficient method of drying wood.

- Involves placing the wood in a specially designed kiln, where temperature, humidity, and airflow are closely monitored and controlled.

- Kiln drying can significantly reduce the drying time compared to air drying, typically taking a few days to weeks.

- The controlled environment allows for precise moisture content reduction, resulting in more uniform and predictable results.

Preventing Wood Drying Defects

Wood drying is not without its challenges, as improper drying techniques can lead to various defects in the wood. It is essential to follow some best practices to prevent these defects and achieve optimal drying results:

- Proper stacking and storage: Arrange the wood in a way that allows for adequate airflow and prevents the trapping of moisture between the boards.

- Controlling temperature and humidity: Maintain appropriate temperature and humidity levels during the drying process to prevent excessive drying or uneven moisture loss.

- Regular monitoring: Regularly check the moisture content of the wood using a moisture meter and track its progress throughout the drying process.

- Gradual drying: Avoid rapid drying methods or exposing the wood to extreme heat, as it can lead to drying stresses and defects like checks or splits.

Conclusion

Understanding the basics of wood drying is crucial for any woodworker aiming to create high-quality and long-lasting woodworking projects. By properly drying wood, woodworkers can enhance the stability, strength, and overall performance of their creations. Whether using air drying or kiln drying, following best practices and monitoring the drying process are key to achieving optimal results.

Methods of Drying Wood: Pros and Cons

Drying wood is an essential process in woodworking to ensure that the wood is stable and free from any structural issues. There are several methods available for drying wood, each with their own pros and cons. Below, we will discuss the most common methods of drying wood and their advantages and disadvantages.

Air Drying

-

Pros: Air drying is a natural and low-cost method of drying wood. It requires minimal equipment and can be done outdoors. This method allows the wood to dry slowly, which reduces the risk of cracking and warping. Additionally, air-dried wood tends to have a more natural color and appearance.

-

Cons: Air drying is a slow process and can take several months or even years depending on the species and thickness of the wood. It is also highly dependent on the environmental conditions, such as humidity and temperature. Additionally, there is an increased risk of insect infestation and fungal growth when drying wood outdoors.

Kiln Drying

-

Pros: Kiln drying is a controlled and efficient method of drying wood. It allows for faster drying times compared to air drying, as the wood is exposed to specific temperature and humidity levels. Kiln-dried wood has reduced moisture content, making it more stable and less prone to cracking. The process also helps to kill any insects and fungi present in the wood.

-

Cons: Kiln drying requires specialized equipment, such as a kiln or a drying chamber, which can be expensive to set up and operate. The drying process can also cause the wood to lose some of its natural color and may result in slight shrinkage. Additionally, improper kiln drying can lead to drying defects, such as case hardening or internal stresses.

Vacuum Drying

-

Pros: Vacuum drying is a method that combines heat and pressure to remove moisture from wood. It allows for faster drying times compared to air or kiln drying. The process also helps to preserve the natural color and appearance of the wood. Vacuum-dried wood is typically more stable and less prone to warping or splitting.

-

Cons: Vacuum drying requires specialized equipment and is a more expensive method compared to air or kiln drying. It is also a complicated process that requires careful control of temperature and pressure. Improper vacuum drying can result in uneven drying or damage to the wood.

Conclusion

Each method of drying wood has its own advantages and disadvantages. The choice of drying method depends on various factors, such as the desired drying time, available resources, and desired outcome in terms of wood stability and appearance. It is important to consider these factors and select the most suitable method for drying wood in your woodworking projects.

Seasoning Wood: Air Drying vs. Kiln Drying

When it comes to preparing wood for woodworking projects, one important step is to properly season the wood. Seasoning involves removing moisture from the wood to stabilize it and improve its workability. There are two common methods for accomplishing this: air drying and kiln drying.

Air Drying

Air drying is a traditional method of seasoning wood that involves simply leaving the wood to dry naturally in the open air. It is a low-cost method that has been used for centuries. Here are some key points about air drying:

- Time: Air drying can take a long time, often several months or even years, depending on the thickness and type of wood. Thicker pieces of wood generally require more time to dry.

- Environment: Air drying requires a suitable environment that provides good air circulation and protection from rain. Ideally, the wood should be stacked with spacers between the boards to allow air to flow freely.

- Control: Air drying does not provide as much control over the drying process compared to kiln drying. The wood is exposed to the natural elements, which can result in uneven drying and potential defects.

Kiln Drying

Kiln drying is a modern method of rapidly drying wood using specialized equipment called kilns. It is a faster and more controlled method compared to air drying. Here are some key points about kiln drying:

- Time: Kiln drying can significantly reduce the drying time compared to air drying. Depending on the type of wood and thickness, the process can take anywhere from a few days to several weeks.

- Environment: Kiln drying requires a controlled environment inside the kiln. The temperature, humidity, and airflow can be adjusted to optimize the drying process. This allows for more consistent and uniform drying compared to air drying.

- Control: Kiln drying provides better control over the drying process, resulting in more predictable and lessened defects. However, it requires specialized equipment and expertise.

| Air Drying | Kiln Drying | |

|---|---|---|

| Time | Longer | Shorter |

| Environment | Outdoor, natural | Controlled indoor |

| Control | Less control | More control |

In conclusion, both air drying and kiln drying are viable methods for seasoning wood. Air drying is a traditional, low-cost method that requires more time and relies on natural environmental factors. Kiln drying, on the other hand, is a faster and more controlled method that requires specialized equipment and expertise. Ultimately, the choice between the two methods depends on the specific needs and constraints of the woodworking project.

Factors Affecting Wood Drying Time

Several factors can impact the drying time of wood. It is important to consider these factors when planning a woodworking project to ensure that the wood is properly dried and ready for use. The following are some key factors that can affect the drying time of wood:

- Wood species: Different wood species have different moisture content and properties, which can influence the drying time. For example, hardwoods generally have a slower drying time compared to softwoods.

- Initial moisture content: The initial moisture content of the wood, which is determined by the environment where the tree grew and the time of harvesting, can have a significant impact on the drying time. Wood with a higher initial moisture content will typically take longer to dry.

- Wood thickness: The thickness of the wood can affect the drying time. Thicker pieces of wood will take longer to dry compared to thinner pieces.

- Air circulation: Proper air circulation is essential for efficient wood drying. Good airflow helps to remove moisture from the wood. Without sufficient air circulation, drying time can be prolonged.

- Temperature and humidity: The temperature and humidity levels in the drying environment can significantly affect the drying time. Higher temperatures and lower humidity levels generally accelerate the wood drying process.

- Wood drying method: The method used to dry the wood can impact the drying time. There are several drying methods, including air drying, kiln drying, and solar drying. Each method has its advantages and disadvantages in terms of drying time.

- Wood preparation: Properly preparing the wood before drying can help speed up the drying time. This includes removing bark, splitting the wood, and sealing the end grain to prevent excessive moisture loss.

It is important to note that these factors are interrelated, and their combined effect determines the overall drying time. To achieve the best results, it is recommended to carefully consider these factors and adjust the drying conditions accordingly.

How to Air Dry Wood: Step-by-Step Guide

Air drying wood is a simple and cost-effective method of drying lumber for woodworking projects. By allowing the wood to naturally lose moisture over time, you can achieve a stable and well-seasoned material that is ready for use. To successfully air dry wood, follow these steps:

- Select the right wood: Choose the type of wood that is suitable for air drying. Certain woods, such as oak or pine, dry well in this method, while others may not.

- Prepare the wood: Cut the wood into manageable pieces, removing the bark and any excess branches. Ensure that the pieces are clean and free from insect infestations.

- Create a drying stack: Arrange the wood in a stacking pattern, allowing airflow between each piece. Use sticks or spacers to separate the layers and promote air circulation.

- Find a suitable location: Place the drying stack in a well-ventilated area, protected from direct sunlight and rain. Ideally, the location should have good airflow.

- Monitor the moisture content: Regularly measure the moisture content of the wood using a moisture meter. Aim for a moisture content of around 12-15% for woodworking purposes.

- Rotate the wood: Regularly rotate the wood within the drying stack to ensure even drying. This prevents certain parts from drying faster than others and reduces the risk of warping.

- Allow for sufficient drying time: Air drying can take several months or even a year, depending on the type and thickness of the wood. Patience is key to achieving properly dried wood.

- Finish the drying process: Once the wood has reached the desired moisture content, remove it from the drying stack and let it acclimate in the environment where it will be used for a few weeks.

Remember, air drying wood requires time and patience. Rushing the process may result in wood that is not properly dried and prone to defects. However, the rewards of successfully air drying wood include reduced cost compared to kiln drying and a more natural and stable material for woodworking projects.

How to Kiln Dry Wood: Step-by-Step Guide

Kiln drying wood is a popular method used to speed up the drying process and reduce the moisture content in wood. This process involves using a kiln, which is a controlled environment that ensures optimal drying conditions. In this step-by-step guide, we will explore the kiln drying process for wood.

- Selecting the Wood: Start by selecting the wood you want to kiln dry. It’s important to choose wood that has been properly seasoned before entering the kiln. Green or freshly cut wood will require additional time and energy to dry.

- Preparing the Wood: Before placing the wood in the kiln, it’s necessary to prepare it by cleaning off any dirt, debris, or bark. The wood should be cut into manageable sizes and arranged in uniform stacks for efficient drying.

- Stacking the Wood: Proper stacking of the wood is crucial to ensure even drying. Place spacers or stickers between each layer of wood to allow air circulation. This helps prevent moisture buildup and allows for more effective drying.

- Loading the Kiln: Carefully load the wood into the kiln, making sure there is enough space for air to circulate. Avoid overcrowding the kiln, as this can hinder the drying process. It’s a good practice to leave gaps between the stacks and the kiln walls.

- Setting the Temperature: Depending on the type of wood and desired moisture content, set the temperature in the kiln accordingly. It’s important to monitor and control the temperature throughout the drying process to prevent damage to the wood.

- Monitoring Moisture Levels: Regularly monitor the moisture levels of the wood using a moisture meter. Aim for the desired moisture content depending on the intended use of the wood. It’s advisable to gradually reduce the temperature towards the end of the drying process to prevent stress on the wood.

- Removing the Wood: Once the wood has reached the desired moisture content, it’s time to remove it from the kiln. Allow the wood to cool down before handling it. Note that the drying time can vary depending on several factors such as wood species, initial moisture content, and kiln conditions.

- Storage and Conditioning: After kiln drying, it’s important to properly store and condition the wood. Stack the dried wood in a controlled environment to allow further equalization of moisture content. This will help prevent any warping or distortion when working with the wood in future projects.

By following this step-by-step guide, you can effectively kiln dry wood and achieve a lower moisture content for your woodworking projects. Remember to always prioritize safety and proper monitoring throughout the drying process.

Common Mistakes to Avoid in Wood Drying

Properly drying wood is essential for successful woodworking projects. However, there are several common mistakes that people make during the wood drying process. By avoiding these mistakes, you can ensure that your wood is properly dried and ready for use in your woodworking projects.

- Not using the correct moisture meter: It is important to use a reliable moisture meter to accurately measure the moisture content of the wood. Relying on visual cues or guesswork is not reliable and can lead to improperly dried wood.

- Rushing the drying process: Patience is key when drying wood. Trying to speed up the drying process by increasing the temperature or using excessive airflow can cause the wood to dry too quickly, leading to cracks, warping, and other issues.

- Ignoring the importance of air circulation: Proper air circulation is crucial for effective wood drying. Without adequate airflow, moisture can become trapped in the wood, leading to uneven drying and potential mold or decay.

- Not acclimating wood to the drying environment: Wood should be given time to acclimate to the environment in which it will be dried. This helps prevent the wood from experiencing drastic moisture changes too quickly, which can lead to problems later on.

- Storing wood in an inappropriate location: Choosing the right location for storing the drying wood is essential. Avoid areas with excessive humidity, direct sunlight, or extreme temperature fluctuations, as these can negatively affect the drying process and the quality of the wood.

- Not keeping track of drying progress: It is important to document the drying progress of each piece of wood. This helps you keep track of how long the wood has been drying and allows you to identify any issues or changes that may occur during the process.

Avoiding these common mistakes will greatly increase your chances of successfully drying wood for your woodworking projects. By following proper drying procedures and being patient, you can ensure that your wood is dried evenly, free from defects, and ready for use in your next woodworking masterpiece.

Using Moisture Meters and Hygrometers in Wood Drying

Drying wood for woodworking projects is essential to ensure its stability and prevent potential issues like warping and splitting. To accurately determine the moisture content in wood, professionals and DIY enthusiasts use moisture meters and hygrometers. These tools help measure the moisture levels in the wood and the surrounding environment, ensuring the wood is adequately dried.

Moisture Meters

Moisture meters are handheld devices designed to measure the moisture content of wood quickly. They work using either pin-type or pinless technology:

- Pin-type moisture meters: These devices have two metal pins that are inserted into the wood. The pins measure the electrical resistance between them, which is then converted into moisture content readings.

- Pinless moisture meters: These meters use a scanning mechanism to measure the moisture content without penetrating the wood surface. They work by emitting electromagnetic waves that penetrate the wood and measure the reflections to determine the moisture levels.

Moisture meters typically provide readings as a percentage of the wood’s moisture content. Different types of wood have different desired moisture content, depending on the intended use. For example, furniture-grade wood may have a lower moisture content requirement compared to construction lumber.

Hygrometers

Hygrometers, also known as humidity meters, are used to measure the relative humidity (RH) in the surrounding environment. They are essential in wood drying because the moisture content in wood depends on the humidity level in the air. Too high or too low humidity can affect the drying process and the final moisture content of the wood.

There are two primary types of hygrometers used in wood drying:

- Psychrometer: This type of hygrometer uses two thermometers, one with a wet bulb and one with a dry bulb. The difference between the two temperatures is used to determine the relative humidity.

- Electronic hygrometer: These hygrometers use electronic sensors to measure the moisture content in the air. They provide accurate and instant readings, making them popular among woodworkers.

Importance of Using Moisture Meters and Hygrometers

Properly dried wood is crucial for the success of any woodworking project. Using moisture meters and hygrometers helps woodworkers achieve the following:

- Prevent warping and splitting: By ensuring the wood has reached the recommended moisture content, woodworkers can minimize the risk of warping and splitting once the project is completed.

- Accurate joinery: Wood with higher moisture content tends to shrink as it dries, potentially affecting the accuracy of joinery and compromising the project’s quality.

- Optimal finish: Finishing wood with high moisture content can lead to coatings failing or not drying properly. By drying the wood to the appropriate moisture content, woodworkers can ensure a smooth and durable finish.

- Workshop environment control: Monitoring the humidity levels in the workshop using hygrometers helps woodworkers understand how the environment can affect the drying process and make necessary adjustments.

Overall, moisture meters and hygrometers are essential tools in the wood drying process. They provide reliable measurements and help woodworkers ensure the wood is sufficiently dried for their woodworking projects.

FAQ:

What is the purpose of drying wood for woodworking?

Drying wood is important for woodworking because it helps to reduce moisture content in the wood, which in turn prevents the wood from warping, splitting, or shrinking after it is fashioned into a finished product.

Can I use freshly cut wood for woodworking projects?

Using freshly cut wood for woodworking projects is not recommended because it typically has a high moisture content. This high moisture content can cause the wood to warp, split, or shrink as it dries. It is best to dry the wood properly before using it for woodworking projects.

What are the different methods for drying wood?

There are several methods for drying wood, including air drying, kiln drying, and using a dehumidification kiln. Air drying involves stacking and storing the wood in a dry, well-ventilated area for an extended period of time. Kiln drying involves using a specialized kiln to control temperature and humidity levels to dry the wood quickly. Dehumidification kilns use a combination of fans and dehumidifiers to remove moisture from the wood.

How long does it take to dry wood for woodworking?

The drying time for wood can vary depending on several factors, including the species of wood, the thickness of the wood, and the drying method used. In general, air drying can take several months to a year, while kiln drying can take just a few weeks. It is important to monitor the moisture content of the wood throughout the drying process to ensure it is properly dried before use.

What are some tips for drying wood effectively?

Some tips for drying wood effectively include ensuring proper airflow around the wood during the drying process, regularly checking the moisture content of the wood using a moisture meter, and stacking the wood in a way that allows for good air circulation. It is also important to be patient and allow the wood to dry fully before using it for woodworking projects.