Woodworking templates are essential tools for any woodworker, whether you’re a beginner or an experienced craftsman. Templates help you create precise and consistent shapes and patterns, making your woodworking projects easier and more professional-looking. In this guide, we’ll take you through the step-by-step process of creating a woodworking template, so you can elevate your woodworking skills to the next level.

The first step in creating a woodworking template is to select the right material. The material should be durable and easy to work with, such as plywood or MDF (Medium Density Fiberboard). These materials are readily available at most hardware stores and provide a stable surface for tracing and cutting your template.

Once you have your material, the next step is to decide on the shape or pattern you want to create. This could be anything from a simple circle or square to a more intricate design. You can either draw your shape freehand or use existing templates as a guide. If you’re using an existing template, make sure to resize it to fit your project’s specifications.

After you have your shape or pattern, it’s time to transfer it onto your material. Place the template on top of the material and secure it in place with tape or clamps. Then, using a pencil or marker, trace the outline of the shape onto the material. For more complex patterns, you may need to trace multiple sections and then connect them together.

Once you’ve traced the shape, remove the template and double-check that your outline is clear and accurate. If needed, make any necessary adjustments or corrections. Then, using a jigsaw or a scroll saw, carefully cut along the outline of your shape. Take your time to ensure smooth and clean cuts.

Finally, give your template a finishing touch by sanding the edges and surface. This will remove any rough edges or imperfections and give your template a professional look. You can also add a protective coat of varnish or sealant to prolong its lifespan.

With your woodworking template complete, you can now use it to create multiple identical shapes or patterns for your projects. Templates save you time and effort by eliminating the need to measure and trace each individual piece. They also allow for consistent results, making your finished projects more polished and professional.

So, whether you’re a seasoned woodworker looking to improve your accuracy or a beginner venturing into the world of woodworking, creating your own templates is a valuable skill to have. Follow this step-by-step guide, and you’ll be on your way to creating beautiful and precise woodworking projects.

Step-by-step guide on creating a woodworking template

Woodworking templates are essential tools for creating precise and consistent woodworking projects. They serve as a guide for cutting and shaping wood pieces, ensuring accurate measurements and smooth edges. In this step-by-step guide, we will show you how to create your own woodworking template.

- Choose your design: Start by deciding on the design or pattern you want to create with your woodworking template. It could be a simple shape like a circle or square, or a more complex design like a flower or animal. Sketch out your design on a piece of paper to visualize the layout and dimensions.

- Select suitable materials: Next, choose a material that is sturdy enough to withstand repeated use but easy to work with. Plywood or MDF (medium-density fibreboard) are commonly used for woodworking templates. Measure and mark the dimensions of your design on the chosen material.

- Cut out the template shape: Using a jigsaw or a coping saw, carefully cut along the marked lines of your design. Take your time to ensure clean and precise cuts, as any imperfections will transfer onto your workpieces.

- Create reference markings: To make it easier to align and position your template on your workpiece, create reference markings on the template. These could be center lines, corner markers, or any other guide that will help you accurately position the template while working.

- Smooth the edges: After cutting out the shape, use sandpaper or a file to smooth the edges of the template. This will prevent any rough or jagged edges from damaging your workpiece when using the template.

- Label the template: To avoid confusion when using multiple templates, label the template with its corresponding design or pattern. This will make it easier to identify and select the right template for your project.

- Store and organize: Once your woodworking template is ready, store it in a dry and secure place. Consider organizing your templates in a labeled container or drawer to keep them easily accessible and protected from damage.

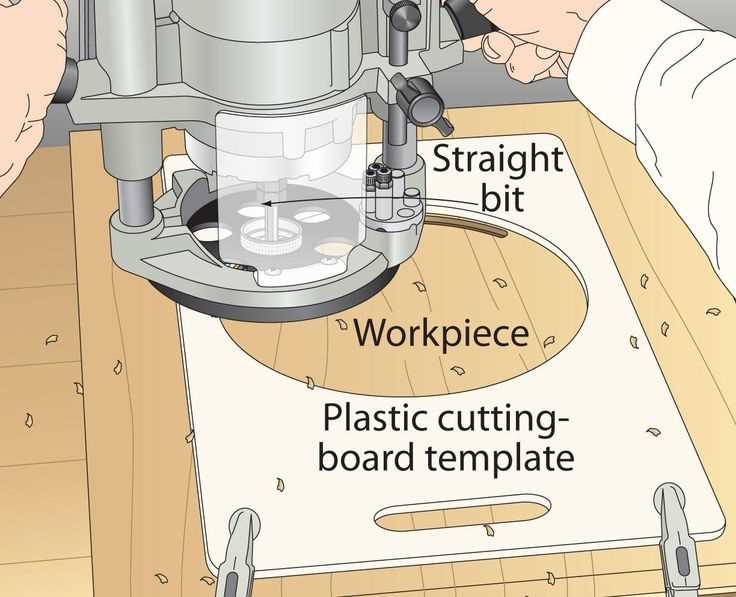

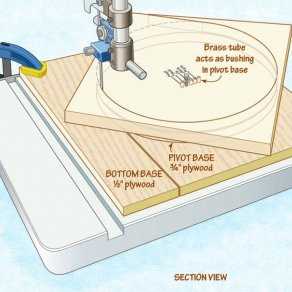

- Use the template: When using your woodworking template, place it on the desired workpiece, aligning the reference markings. Secure it in place with clamps or double-sided tape. Use a router, jigsaw, or other appropriate tools to trace along the edges of the template, following its shape. Repeat the process as needed to create the desired design on your workpiece.

By following this step-by-step guide, you can create your own woodworking template and enhance the accuracy and consistency of your woodworking projects. Templates can be reused multiple times and are valuable tools for replicating designs or patterns in woodworking.

Understanding the Importance

Woodworking templates are crucial tools that help woodworkers create accurate and consistent designs. They are used as guides for shaping and cutting wood, ensuring precise measurements and clean edges. Understanding the importance of woodworking templates can greatly improve the quality and efficiency of your woodworking projects.

1. Accuracy: Woodworking templates provide precise measurements and dimensions, allowing woodworkers to create accurate designs. By following the template, you can ensure that each piece of wood fits perfectly together and that the final result meets your specifications.

2. Consistency: Using the same template for multiple pieces can help you maintain consistency throughout your project. It ensures that each piece is cut, shaped, and assembled in the same way, resulting in a professional-looking final product.

3. Time-saving: Templates simplify the woodworking process by eliminating the need for guesswork and measurements. They can help you save time by providing a clear guide for each step. With a template, you can focus on the actual woodworking instead of spending unnecessary time on calculations and adjustments.

4. Safety: Woodworking templates are designed to be safe and reliable. They reduce the risk of errors and mistakes that can lead to accidents during the cutting and shaping process. By following the template, you can work with confidence, knowing that you are using a proven and tested method.

5. Reproducibility: Woodworking templates can be used repeatedly to create multiple identical pieces. This is particularly useful for projects that require multiple parts, such as furniture or cabinetry. With a template, you can easily reproduce the same design without the need for re-measuring or re-cutting each piece.

6. Customizability: Templates can be customized to fit your specific needs. You can modify existing templates or create your own to match the unique dimensions and shapes required for your project. This allows you to have control over the design process while still benefiting from the accuracy and consistency provided by the template.

Conclusion: Woodworking templates are invaluable tools that can greatly enhance the quality and efficiency of your woodworking projects. By understanding their importance and using them effectively, you can achieve precise and consistent results, saving time and ensuring safety in your woodworking endeavors.

Gathering Materials and Tools

Before you can start creating a woodworking template, you’ll need to gather the necessary materials and tools. Here is a list of what you’ll need:

- Wood: Choose a type of wood that is suitable for your project. Common options include pine, oak, and plywood.

- Measuring Tools: You’ll need measuring tools such as a tape measure, ruler, and a combination square to accurately measure and mark your wood.

- Cutting Tools: A saw is essential for cutting the wood to the desired dimensions. Depending on your project, you may also need a jigsaw or a circular saw.

- Clamps: Clamps are used to hold the wood securely in place while you work on it. They come in various sizes and types, so choose ones that are suitable for your project.

- Drilling Tools: If your project requires making holes, you’ll need a drill and a set of drill bits. A countersink bit is also useful for creating recessed holes.

- Sanding Tools: Sandpaper or a sanding block is necessary to smooth the wood surface and remove any imperfections.

- Safety Equipment: Always prioritize safety when working with tools and wood. Wear protective goggles, gloves, and a dust mask to protect yourself from flying debris and harmful dust particles.

Once you have gathered all the necessary materials and tools, you are ready to move on to the next step in creating your woodworking template.

Taking Accurate Measurements

Accurate measurements are crucial when creating a woodworking template. Whether you are building a piece of furniture or crafting a decorative wood item, precise measurements ensure the final product meets your expectations. Here are some tips to help you take accurate measurements:

- Use a reliable measuring tool: Invest in quality measuring tools such as a tape measure, ruler, or caliper. Make sure they are properly calibrated for accurate measurements.

- Choose the right unit of measurement: Decide whether you will be using inches, centimeters, or another unit of measurement. Stick to a consistent unit throughout the project for accuracy.

- Measure twice: To reduce the chance of errors, measure twice before making any cuts or adjustments. Take your time and double-check your measurements to avoid costly mistakes.

- Account for the length of the tool: When measuring with a tape measure, ensure you account for the length of the tool itself. Start the measurement from the end of the tape, not the beginning.

- Consider the wood’s expansion: Keep in mind that wood can expand or contract due to changes in temperature and humidity. Take this into consideration when measuring and allow for any potential changes in size.

By following these tips, you can ensure your woodworking template is based on accurate measurements. Taking the time to measure correctly will save you from frustration and rework down the road.

Designing the Template

Before you start creating a woodworking template, it’s important to design it first. This will ensure that you have a clear vision of the final product and will help you anticipate any challenges or modifications that may arise during the process. Here are some steps to consider when designing your template:

- Determine the purpose: Decide what specific purpose the template will serve. Will it be used for marking cuts, measuring dimensions, or guiding the placement of various woodworking elements?

- Choose the material: Select a suitable material for your template, taking into account factors such as durability, flexibility, and ease of use. Common options include plywood, MDF, or acrylic.

- Measurements and dimensions: Accurately measure the required dimensions for your template. Use a combination of rulers, calipers, and measuring tapes to ensure precision.

- Consider ergonomics: Think about how the template will be used and handled. Design it with ergonomic considerations in mind, such as comfortable grip handles or rounded edges to prevent injuries.

- Create a layout: Sketch a rough layout of your template design, detailing the different sections, markings, and cutouts required. This will serve as a visual guide during the construction process.

- Test and iterate: Once you have a design, create a prototype or a mock-up to test its usability and effectiveness. Observe any areas that might need improvement and make necessary adjustments before finalizing the template.

Remember, the design phase is crucial to ensure that your woodworking template meets your specific needs and requirements. Take your time and consider all the factors mentioned above to create a functional and efficient template for your woodworking projects.

Transferring the Design to the Material

Once you have created your woodworking template, it’s time to transfer the design onto the material you will be working with. This step is crucial for ensuring accuracy and precision in your woodworking project. Here are the steps to transfer your design:

- Gather your materials: You will need your woodworking template, the material you will be working with (such as wood or plywood), a pencil or marker, and masking tape.

- Prepare the material: Make sure the surface of the material is clean and free from any dust or debris. Sand down any rough edges or imperfections that may interfere with the transfer of the design.

- Position the template: Place the woodworking template on top of the material and align it according to your desired placement. Use masking tape to secure the template in place, making sure it doesn’t move during the transfer process.

- Trace the design: Using a pencil or marker, carefully trace the outline of the design onto the material. Take your time to ensure that the lines are accurate and well-defined.

- Remove the template: Once you have traced the entire design, gently remove the woodworking template from the material. Be careful not to smudge or distort the traced lines.

- Double-check and refine: Take a moment to review the transferred design and make any necessary adjustments or refinements. Use a ruler or measuring tape to ensure that all measurements and proportions are correct.

With the design successfully transferred onto the material, you are now ready to proceed with the woodworking project. Whether you are cutting, carving, or shaping the material, having the design clearly marked will help guide your actions and ensure a more precise result.

Cutting and Shaping the Template

Once you have your woodworking template design finalized, it’s time to start bringing it to life by cutting and shaping the template. This step is crucial in ensuring the accuracy and precision of your final woodworking project.

Materials needed:

- Plywood or MDF board

- Jigsaw or coping saw

- Sandpaper or a hand plane

- Clamps

Step 1: Transfer the template design

- Place the template design on top of the plywood or MDF board.

- Secure the template design and the board with clamps to prevent movement.

- Use a pencil or marker to trace the outline of the template design onto the board.

Step 2: Cut out the template shape

- Using a jigsaw or coping saw, carefully cut along the traced outline of the template design.

- Take your time and make precise cuts to ensure the shape is accurate.

- Follow any curves or intricate details of the design as closely as possible.

Step 3: Refine the template shape

- After cutting out the template shape, use sandpaper or a hand plane to refine the edges and make them smoother.

- Remove any rough spots or uneven edges.

- Regularly check the template against the design to ensure it matches perfectly.

Step 4: Test the template

- Before using the template for your woodworking project, it’s essential to test it out on a scrap piece of wood.

- Place the template on the wood and trace around it.

- Cut out the shape and check for any discrepancies or adjustments that need to be made.

By carefully cutting and shaping the template, you’ll have a reliable guide to follow when working on your woodworking project. Remember to always double-check the template against the design to ensure accuracy before proceeding to the next step.

Fine-tuning and Adjusting the Template

After creating a woodworking template, it is important to fine-tune and adjust it to ensure optimal results. Here are some key steps to consider when fine-tuning and adjusting your woodworking template:

- Inspect the Template: Start by carefully inspecting the template for any imperfections or errors. Look for any rough spots, misalignments or irregularities that may need to be corrected.

- Sand and Smooth: If you notice any rough spots or areas that need smoothing, use sandpaper to gently remove them. Sanding the template will help ensure a clean and smooth finish on your woodworking project.

- Check Dimensions: Verify that the dimensions of the template are accurate and match the desired measurements for your project. Use a ruler or measuring tape to double-check the template’s dimensions.

- Make Adjustments: If the template’s dimensions do not match your requirements, make necessary adjustments. This may involve trimming, reshaping, or enlarging certain areas of the template to achieve the desired dimensions.

- Precision is Key: Pay attention to small details and ensure precise measurements when making adjustments to the template. Even minor inaccuracies can greatly affect the outcome of your woodworking project.

- Test the Template: Before using the template on your actual woodworking project, it is always a good idea to test it on a scrap piece of wood. This will allow you to evaluate if any further adjustments or modifications are needed.

By following these steps and fine-tuning your woodworking template, you will be able to achieve accurate and precise results in your woodworking projects. Remember to take your time and make necessary adjustments to ensure the best outcome.

Testing and Finalizing the Template

Once you have created your woodworking template, it is important to test it thoroughly to ensure its accuracy and functionality. This step-by-step guide will walk you through the process of testing and finalizing your template.

Step 1: Review the Design

Before starting the testing process, take a moment to review the design of your template. Make sure that it follows the woodworking project specifications and meets all the required dimensions and measurements.

Step 2: Measure with Precision

Using accurate measuring tools, carefully measure the various elements of the template. Double-check all the measurements to ensure their precision. Any inaccuracies at this stage can lead to errors in the final woodworking project.

Step 3: Test Assembly

Assemble the template and the corresponding components to check if they fit together correctly. Make any necessary adjustments or modifications to ensure a proper fit.

Step 4: Test Durability and Strength

Test the strength and durability of the template by applying pressure or stress to different parts. Check for any weak points or potential areas that may need reinforcement.

Step 5: Confirm Ergonomics and Functionality

Check the ergonomics and functionality of the template by simulating the woodworking process. Ensure that it allows for easy and comfortable handling, and that it facilitates necessary woodworking techniques.

Step 6: Obtain Feedback

Share your template with other woodworking enthusiasts or experts to get their feedback. Listen to their suggestions and make necessary adjustments to improve the template.

Step 7: Finalize the Template

After addressing any issues or feedback, finalize the template. Make sure that all the measurements, angles, and components are accurately represented in the final design.

Step 8: Document the Template

Document the finalized template by creating detailed instructions and diagrams. Include step-by-step procedures, measurements, and any additional notes to assist others in using the template.

Step 9: Store and Use the Template

Store the finalized template in a safe and accessible location, such as a labeled folder or drawer. When starting a woodworking project, refer to the template to ensure accuracy and consistency in your work.

By following these steps and thoroughly testing your woodworking template, you can ensure that it is accurate, functional, and reliable for use in your woodworking projects.

Woodworking Templates 101

A woodworking template is an essential tool for any woodworker. It is a guide or pattern that helps woodworkers replicate and create precise cuts and shapes in their projects. Templates can be made from various materials such as wood, plastic, or metal, and they can be used for different purposes, including routing, carving, or shaping wood.

Creating a woodworking template involves several steps:

- Design the Template: Start by designing the desired shape or pattern on paper or using design software. Consider the dimensions and proportions carefully to achieve the desired outcome.

- Choose the Material: Select a material suitable for your project. Wood or plywood is commonly used for templates, but plastic or metal can also be used for more intricate designs or when longevity is a concern.

- Transfer the Design: Transfer the design onto the chosen material. You can do this by tracing the pattern onto the material using carbon paper, or by printing and adhering a paper template onto the material.

- Cut the Template: Use appropriate cutting tools to cut the template along the design outline. Depending on the material, you can use a jigsaw, bandsaw, or scroll saw to accomplish this step. Take your time and make precise cuts to ensure an accurate template.

- Refine and Sand: After cutting, refine the template by sanding the edges and surface. This step is crucial for achieving smooth and accurate results when using the template on your woodworking projects.

- Label and Store: To avoid confusion, label the template with relevant information such as the project it is intended for or any specific instructions. Store the template in a safe place where it won’t get damaged or misplaced.

Once you have created the woodworking template, it can be used repeatedly to create consistent and accurate shapes in your projects. Templates save time and effort and allow woodworkers to focus on the fine details of their craftsmanship.

Note: When using a template, it is essential to secure it firmly to the workpiece to prevent any movement or slippage, which can lead to inaccuracies in the final result.

Woodworking templates are versatile tools that can be used in various woodworking projects. From simple cuts to complex shapes, templates provide a reliable guide for creating consistent and high-quality work. Whether you are a beginner or an experienced woodworker, using templates can enhance your woodworking skills and help you achieve excellent results.

FAQ:

Why do I need a woodworking template?

A woodworking template is a very useful tool for woodworkers as it helps to ensure accuracy and consistency in their projects. By using a template, woodworkers can easily replicate shapes and patterns, saving time and effort.

How do I create a woodworking template?

Creating a woodworking template involves several steps. First, you need to design the shape or pattern you want to replicate. Then, you can either trace the design onto a piece of plywood or use a computer-aided design (CAD) software to generate a digital template. Finally, you can cut out the template using a saw or a router.

What materials can I use for woodworking templates?

Woodworking templates can be made from a variety of materials. Plywood is commonly used due to its availability and ease of cutting. However, other options include acrylic, MDF (medium-density fiberboard), or even metal, depending on the specific requirements of the project.

Are there any tips for using woodworking templates?

Yes, here are a few tips for using woodworking templates. First, make sure the template is securely attached to the workpiece to avoid any shifting during cutting. Additionally, use clamps or weights to hold the template in place if needed. It’s also a good idea to practice on scrap wood before cutting into your final workpiece to ensure the template is accurately positioned.