Clay is the essential material used in pottery, and its cost plays a significant role in determining the overall expense of the craft. Whether you are a beginner or an experienced potter, understanding the various factors that affect the cost of clay is crucial.

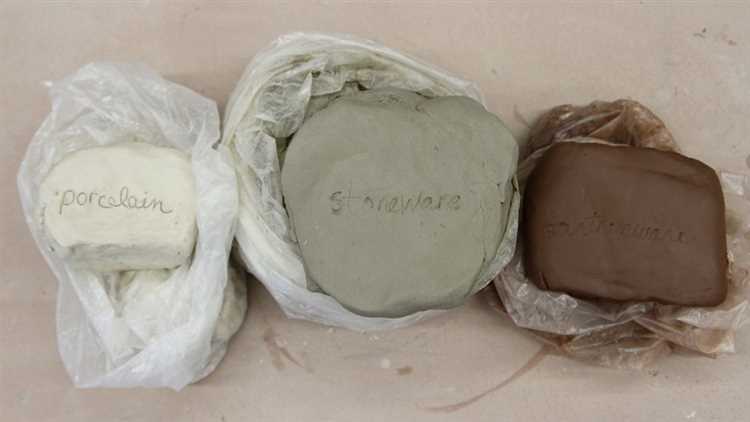

First and foremost, the type of clay you choose will greatly impact its price. There are several types of clay available, including earthenware, stoneware, and porcelain. Each type has its own unique characteristics and cost considerations. Higher-quality clays often come with a higher price tag, but they provide superior results in terms of durability and aesthetics.

Another factor to consider is the quantity of clay you require. Clay is typically sold in various package sizes, ranging from small pints to larger bulk quantities. Purchasing clay in larger quantities can be more cost-effective in the long run, but it also requires careful planning and storage considerations.

It is important to note that the cost of clay is not limited to just the raw material itself. Additional expenses, such as shipping fees or sales taxes, may also be applicable when purchasing clay.

Lastly, the location from which you source your clay may affect its cost. Clay that is locally sourced may be more affordable due to reduced transportation costs. However, if you choose to use specialty clays from specific regions, they may come with a higher price due to their unique characteristics or availability. Thus, it is essential to research different suppliers to find the best balance between quality and cost.

The Importance of Clay in Pottery Making

Clay is an essential material in the art of pottery making. It is the primary component used by potters to create various ceramic objects such as bowls, vases, and figurines. The unique properties of clay make it an ideal material for shaping and firing into durable and functional pieces.

Here are some key reasons why clay is so important in pottery making:

- Malleability: Clay has a unique plasticity that allows it to be easily shaped and molded by hand or on a potter’s wheel. This gives potters the ability to create intricate designs and details in their works.

- Durability: When clay is fired in a kiln at high temperatures, it undergoes a chemical transformation and becomes significantly more durable. Fired clay pottery can last for centuries when properly cared for.

- Versatility: Clay can be manipulated into various forms and sizes, making it suitable for creating a wide range of pottery objects. From small delicate cups to large sculptural pieces, clay provides endless possibilities for artistic expression.

- Texture: The different types of clay available in pottery have distinct textures that can add visual and tactile interest to finished pieces. Smooth, sandy, or groggy clay can create unique surface finishes and enhance the overall aesthetic of the artwork.

- Interaction with glazes: Clay acts as a canvas for various glazes, which are applied to pottery to add color, shine, and protection. Different types of clay can react differently with glazes, resulting in a wide range of beautiful and distinctive finishes.

Overall, clay is the foundation of pottery making and plays a crucial role in the creation of functional and decorative ceramic objects. Without clay, the art of pottery as we know it would not be possible.

Why Does Clay Matter for Pottery?

Clay is a fundamental material for pottery and plays a crucial role in the creation of ceramic objects. Its unique properties make it an ideal medium for shaping, molding, and firing pottery.

1. Plasticity: One of the most important properties of clay is its plasticity. Plasticity refers to the clay’s ability to be shaped and molded without cracking or breaking. This property allows potters to create intricate and detailed forms by hand or using various techniques such as throwing on a pottery wheel or coiling.

2. Porosity: Clay is naturally porous, meaning it has tiny spaces or pores between particles. This porosity is crucial as it allows the clay to absorb and retain water, making it workable and allowing potters to manipulate its shape. However, the porosity of clay can also affect the final outcome of a pottery piece, as it determines its capacity to hold glazes or liquids.

3. Firing: Clay undergoes a transformation when fired in a kiln. It hardens and becomes durable, making it a permanent material for creating pottery. Depending on the type of clay and firing temperature, it can change in color, texture, and strength. Firing clay is essential for pottery as it enables potters to create functional and decorative objects that can withstand everyday use.

4. Types of Clay: There are various types of clay available for pottery, each with its own unique characteristics. Porcelain clay, for example, is smooth and white, making it suitable for creating delicate and refined ceramics. Stoneware clay is known for its durability and is often used for functional pottery. Earthenware clay is more porous and is commonly used for decorative pieces.

5. Cost Considerations: The type of clay used for pottery can also affect the cost of creating ceramic objects. Some clays, such as porcelain, can be more expensive due to their refined qualities and manufacturing processes. The cost of clay can influence the overall pricing of pottery pieces, as it is a primary material used in their production.

6. Artistic Expression: Clay provides artists and potters with an endless range of possibilities for artistic expression. Its versatility allows for experimentation and exploration of various forms, textures, and finishes. The properties of clay contribute to the uniqueness and individuality of each pottery piece, making it a vital element in the world of ceramics.

Different Types of Clay for Pottery

There are several types of clay that are commonly used for pottery, each with its own unique properties and characteristics. Here are some of the most popular types of clay:

- Earthenware Clay: This type of clay is fired at a low temperature and is known for its porous and absorbent nature. It is often used for creating ceramics that are not meant to hold liquids, such as decorative pieces and sculptures.

- Stoneware Clay: Stoneware clay is fired at a higher temperature than earthenware clay, which makes it stronger and less porous. It is a popular choice for functional pottery such as mugs, bowls, and plates.

- Porcelain Clay: Porcelain clay is known for its smooth and delicate finish. It is fired at a very high temperature, resulting in a strong and non-porous ceramic. Porcelain is commonly used for creating fine china, vases, and jewelry.

- Raku Clay: Raku clay is a type of low-fire clay that is often used for the raku firing technique. This technique involves removing the pottery from the kiln while it is still hot and placing it in a combustible material to create unique and unpredictable patterns on the surface.

- Sculpting Clay: Sculpting clay, also known as modeling clay, is a type of clay that is specifically designed for sculpting. It is usually non-drying and comes in various colors, making it ideal for creating intricate sculptures and models.

It’s important to note that each type of clay requires different firing temperatures and techniques, so it’s essential to choose the right clay for your specific pottery project.

Finding the Right Clay for Your Pottery Project

Choosing the right clay for your pottery project is essential to its success. With so many different types of clay available, it can be overwhelming to know which one to choose. This guide will help you understand the different types of clay and their characteristics, so you can make an informed decision.

1. Porcelain Clay

Porcelain clay is known for its beautiful white color and smooth texture. It is a fine-grained clay that is often used for delicate and intricate pottery designs. Porcelain clay can be challenging to work with, as it has a tendency to warp or crack during drying and firing. However, if you are looking for a high-quality finish, porcelain clay is an excellent choice.

2. Earthenware Clay

Earthenware clay is a low-fire clay that is suitable for beginners and pottery projects that do not require high durability. It is known for its warm, red or orange color and is often used to create rustic or traditional pottery pieces. Earthenware clay has a higher moisture content than other clay types, making it easier to work with and shape.

3. Stoneware Clay

Stoneware clay is a mid-range clay that is fired at a higher temperature than earthenware clay. It is known for its strength and durability, making it an excellent choice for functional pottery pieces like mugs and bowls. Stoneware clay has a wide range of colors and textures, allowing for a variety of finishes and glaze effects.

4. Raku Clay

Raku clay is a type of clay that is specifically designed for the raku firing technique. It is a low-fire clay that has a unique composition, allowing for dramatic color changes and crackling effects during firing. Raku clay is often used to create decorative pottery pieces with a rustic or metallic look.

5. Sculpture Clay

Sculpture clay is a clay body that is specifically formulated for sculpting and handbuilding. It is often a blend of different types of clay, designed to have specific working properties. Sculpture clay has a higher grog content, which provides strength and reduces shrinkage during drying and firing. It is an excellent choice for creating three-dimensional pottery pieces.

6. Choosing the Right Clay for Your Project

When choosing the right clay for your pottery project, consider the following factors:

- Firing Temperature: Different clay types require different firing temperatures. Make sure the clay you choose matches the firing temperature of your kiln.

- Intended Use: Consider whether your pottery piece will be functional or decorative. Some clay types are better suited for specific purposes.

- Working Properties: Each clay type has its own working properties, such as plasticity, porosity, and drying time. Consider these properties to ensure the clay is suitable for your desired techniques.

- Cost: The cost of clay can vary depending on the type and quality. Consider your budget when choosing the right clay for your project.

By considering these factors and understanding the characteristics of different clay types, you can find the right clay for your pottery project and create beautiful and successful pieces.

Factors Affecting the Cost of Clay

1. Clay Type: The type of clay used can greatly impact its cost. Different types of clay, such as earthenware, stoneware, and porcelain, vary in terms of their availability and processing requirements. Some clays may be more expensive due to their scarcity or the difficulty of extracting and refining them.

2. Quality: The quality of clay plays a significant role in determining its cost. Higher quality clays, which possess finer particle sizes, better plasticity, and higher firing temperatures, are often more expensive. Clay with impurities or inconsistent composition may be cheaper but could result in lower-quality pottery.

3. Source and Transportation: The source of the clay and the distance it needs to be transported can affect its cost. Clay obtained locally may be more affordable, as transportation costs are lower. However, if the desired clay is sourced from far away, the cost of shipping or transportation can significantly increase the overall price.

4. Processing and Preparation: The processing and preparation required for clay can impact its cost. Clay that requires extensive refining, grinding, or additives to improve its properties may be more expensive. Additionally, if the clay needs to be processed into specific forms or sizes before use, it can add to the overall cost.

5. Quantity Purchased: The quantity of clay purchased can also impact its cost. Buying clay in bulk or larger quantities often results in lower prices per unit compared to purchasing small amounts. Many suppliers offer discounts or reduced rates for larger orders, making it more cost-effective for professional potters or ceramics studios.

6. Market Demand: Market demand for specific types of clay can influence its cost. If a particular clay type is in high demand, its price may be higher due to limited availability. Conversely, if there is less demand, the price may be lower, and suppliers may offer discounts or promotions to attract buyers.

7. Currency Exchange Rates: Currency exchange rates can also affect the cost of clay, especially if it is imported from another country. Fluctuations in currency values can result in price variations, making clay more expensive or affordable depending on the exchange rate at the time of purchase.

8. Packaging and Storage: The packaging and storage method used for clay can also contribute to its cost. Clay that is packaged in specialized containers or requires specific storage conditions may be more expensive. Additionally, if clay needs to be shipped in a way that ensures its safety and prevents moisture or contaminants, it may increase the overall cost.

Considering these factors is essential for potters and ceramic artists when planning their budgets and selecting the appropriate clay for their projects. Understanding the cost determinants helps ensure a cost-effective and quality choice, resulting in satisfactory pottery creations.

Understanding Clay Pricing

When it comes to purchasing clay for pottery, understanding the pricing structure can be helpful in making informed decisions. Clay prices can vary based on various factors. Here are some important points to consider:

- Clay Type: Different types of clay have different prices. The type of clay you choose will depend on your specific needs and preferences.

- Quantity: The quantity of clay you purchase can affect the price. Larger quantities often come at a discounted rate, so it may be more cost-effective to buy in bulk.

- Brand: Clay prices can also vary based on the brand. Some well-known brands may have higher prices due to their reputation and quality. However, lesser-known brands may offer comparable quality at a lower price.

- Additional Features: Some types of clay may come with additional features or additives that can affect the price. For example, clay with added grog or sand may be priced differently than regular clay.

It’s important to compare prices from different suppliers to ensure you’re getting the best deal. Keep in mind that while price is an important factor, it should not be the sole deciding factor. Consider the quality, suitability, and reputation of the clay as well.

Additionally, it’s a good idea to factor in any additional costs such as shipping or delivery charges. Sometimes a slightly higher-priced clay may end up being more cost-effective when considering these factors.

Remember, clay is the foundation of your pottery projects, so investing in quality clay that meets your specific requirements is essential. By understanding the pricing structure and considering all relevant factors, you can make an informed decision and get the most value for your money.

Calculating the Cost of Clay for Pottery

When it comes to pottery, calculating the cost of clay is an important factor in determining the profitability of your projects. By understanding how to calculate the cost of clay, you can make informed decisions about pricing your pottery pieces, managing your expenses, and maximizing your profits.

Step 1: Determine the Type of Clay

There are different types of clay available for pottery, each with its own cost. Some common types of clay include earthenware, stoneware, and porcelain. Determine the type of clay you are using for your pottery project, as this will affect the overall cost.

Step 2: Calculate Clay Consumption

Next, you need to calculate the amount of clay you will be using for your project. This can be done by estimating the weight of clay required for each piece. Keep in mind that clay shrinkage occurs during the drying and firing process, so you may need to account for this in your calculations.

Step 3: Determine Clay Cost per Pound

Once you know the amount of clay you will be using, you can determine the cost per pound for the specific type of clay you are using. This information can usually be obtained from your clay supplier or by researching local clay prices. Keep in mind that clay prices can vary based on location and quality.

Step 4: Calculate Total Clay Cost

Multiply the amount of clay consumed in pounds by the cost per pound to calculate the total cost of clay for your project. This will give you an estimate of how much the clay itself contributes to the overall cost of your pottery.

Step 5: Consider Additional Costs

It’s important to keep in mind that the cost of clay is just one aspect of the overall expenses involved in pottery. Other factors, such as glazes, kiln firing costs, and studio rent, should also be taken into account when calculating the total cost of your pottery projects.

Step 6: Adjust Pricing and Evaluate Profit

Once you have calculated the cost of clay and considered other expenses, you can adjust your pricing accordingly. By understanding the cost of clay and factoring in all other expenses, you can determine a suitable price for your pottery pieces and evaluate the profitability of your projects.

In conclusion, calculating the cost of clay for pottery involves determining the type of clay, calculating clay consumption, determining clay cost per pound, calculating the total clay cost, considering additional costs, and adjusting pricing accordingly. By carefully calculating the cost of clay, you can make informed decisions about pricing and maximize your profits in the world of pottery.

Where to Buy Clay for Pottery

If you’re interested in pottery and need to purchase clay, there are several options available to you. Here are some places to consider:

- Local Pottery Supply Stores: Many cities have pottery supply stores that carry a variety of clay types. These stores often have knowledgeable staff who can help you choose the right clay for your needs.

- Online Retailers: Several online retailers specialize in selling pottery supplies, including clay. They offer a wide selection of clay types and packages that can be delivered right to your doorstep.

- Art Supply Stores: Some art supply stores carry a limited selection of pottery supplies, including clay. While their selection may be smaller, they can still be a convenient option if you don’t have a pottery supply store nearby.

- Local Pottery Studios and Schools: If there are pottery studios or schools in your area, they may sell clay to the public. This can be a great option as you can often find locally sourced clays and support the local pottery community.

When buying clay, consider the type of pottery you’re planning to create and choose a clay body that suits your needs. It’s also important to check the clay’s moisture content and whether it requires any special handling or firing techniques.

Before making a purchase, compare prices and read reviews to ensure you’re getting a good quality clay for the most reasonable price. Additionally, don’t be afraid to reach out to other potters or communities for recommendations and advice on where to buy clay.

| Pros | Cons | |

|---|---|---|

| Local Pottery Supply Stores |

|

|

| Online Retailers |

|

|

| Art Supply Stores |

|

|

| Local Pottery Studios and Schools |

|

|

Remember, buying clay is an important investment in your pottery journey, so take your time to research the best options for your needs and budget. Happy potting!

Tips for Making the Most of Your Clay Purchase

When purchasing clay for pottery, it’s important to make the most of your investment. Here are some tips to help you get the most out of your clay purchase:

- Calculate your needs: Before making a purchase, calculate how much clay you’ll need for your projects. Consider the size and number of pieces you plan to make, as well as any potential waste. This will help you determine the quantity of clay to buy.

- Consider clay types: Different clay types have different characteristics, so consider the specific needs of your projects. Stoneware clay, for example, is strong and durable, making it ideal for functional pottery. Porcelain clay, on the other hand, is known for its smooth texture and translucency, perfect for delicate pieces.

- Buy in larger quantities: Purchasing clay in larger quantities can often lead to cost savings. If you know you’ll be using clay frequently, consider buying larger bags or bulk orders to save money in the long run.

- Store clay properly: Clay can dry out and become unusable if not stored correctly. Always seal your clay bags tightly to prevent moisture loss. Additionally, consider storing your clay in a cool, dry place to maintain its freshness and pliability.

- Recycle and reuse: Don’t let excess clay go to waste. Save any leftover or trimmed pieces for future projects. You can easily recycle and reuse clay by soaking dry clay scraps in water and reconditioning them. This can help you maximize your clay supply and minimize waste.

- Take care of your tools: Properly maintaining your pottery tools can help extend their lifespan and save you money. Ensure that your tools are clean and dry after each use. Regularly sharpen blades and replace worn-out tools to avoid reworking clay unnecessarily.

By following these tips and strategies, you can make the most of your clay purchase and create beautiful pottery without breaking the bank.

FAQ:

What is the average cost of clay for pottery?

The average cost of clay for pottery can vary depending on various factors such as the type of clay, quantity needed, and location. On average, a 25-pound bag of clay can range from $10 to $25.

Where can I buy clay for pottery?

Clay for pottery can be purchased from various sources such as art supply stores, pottery supply stores, and online retailers. Some popular places to buy clay include local pottery studios, ceramic supply companies, and websites like Amazon and Blick Art Materials.

What are the different types of clay used for pottery?

There are several different types of clay used for pottery, including earthenware clay, stoneware clay, and porcelain clay. Earthenware clay is low-fire clay that is typically red or tan in color, stoneware clay is a high-fire clay that is known for its durability, and porcelain clay is a fine-textured, white clay that is often used for delicate pottery.

How much clay do I need for pottery?

The amount of clay you need for pottery can vary depending on the size and thickness of your project. As a general guideline, you can estimate that 1 pound of clay will yield approximately 3-4 small pottery pieces or 1-2 larger pieces.

Can I make my own clay for pottery?

Yes, it is possible to make your own clay for pottery. Homemade clay recipes typically include a mixture of clay minerals, such as kaolin, ball clay, or fire clay, along with other ingredients like water, sand, and grog. However, making your own clay can be time-consuming and may not always yield the same results as commercially produced clay.

What factors should I consider when buying clay for pottery?

When buying clay for pottery, there are several factors to consider. These include the type of clay, the firing temperature it requires, its plasticity and workability, its color and texture, and its cost. It’s also important to consider the specific needs of your project and choose a clay that is suitable for your intended purpose.