Knitting has long been a traditional craft, with people creating beautiful clothing and textiles by hand for centuries. However, with the advancement of technology, automated knitting machines are becoming more prevalent in the textile industry. These machines are capable of producing intricate patterns and designs with speed and precision, raising the question: can machines truly knit?

Automated knitting machines use computer-controlled technology to manipulate yarn and create knitted fabrics. They are able to replicate complex knitting techniques, such as cables and lace, that were once only achievable by skilled hand-knitters. This technology has revolutionized the textile industry, allowing for faster and more efficient production of knitted goods.

While machines can replicate the physical action of knitting, some argue that true knitting requires the artistic touch and creativity of a human knitter. Knitting is not just about the end product, but also about the process and the connection between the knitter and the project. A machine may be able to create a beautiful knitted garment, but it lacks the emotional investment and personal expression that comes with hand-knitting.

Despite this debate, there is no denying the capabilities of automated knitting technology. These machines have the ability to produce large quantities of knitted items with consistent quality and precision. They can also knit at a much faster rate than a human, making them a valuable asset in the fast-paced fashion industry. As technology continues to advance, it is likely that automated knitting machines will become even more sophisticated and capable.

In conclusion, while machines may be able to knit, they cannot fully replicate the intricacies and artistry of hand-knitting. However, the capabilities of automated knitting machines cannot be ignored. They provide a valuable tool for mass production and allow for the creation of complex patterns and designs that were once only achievable by hand. As the textile industry continues to evolve, it will be interesting to see how machines and human knitters can work together to create beautiful and innovative knitted products.

Advancements in Automated Knitting

The field of automated knitting technology has witnessed significant advancements in recent years. From simple knitting machines to sophisticated computer-controlled systems, the capabilities of automated knitting continue to evolve and revolutionize the textile industry.

- Improved Precision: One major advancement in automated knitting is the increased precision and accuracy achieved by computerized machines. These machines can follow complex patterns with intricate designs, resulting in precise and consistent knitting.

- Efficiency and Speed: Automated knitting technology has greatly improved the efficiency and speed of the knitting process. With computer-controlled machines, the production time for knitted fabrics has significantly reduced, allowing manufacturers to meet increasing demand in a timely manner.

- Customization: Another significant advancement is the ability of automated knitting machines to produce customized designs and patterns. By inputting specific instructions into the computer, these machines can create unique knitted products tailored to individual customer preferences.

- Complex Structures: Automated knitting technology has also enabled the creation of complex structures that were difficult or impossible to produce manually. These machines can seamlessly knit intricate textures, shapes, and even three-dimensional designs.

Furthermore, the integration of automated knitting technology with other digital technologies, such as 3D modeling and simulation, has further expanded the capabilities of these machines. This integration allows designers to visualize and test their designs virtually before production, saving time and resources.

Moreover, automated knitting machines are becoming more user-friendly, with intuitive interfaces and simplified programming. This makes it easier for designers and operators to utilize the full potential of these machines without extensive technical expertise.

Overall, the advancements in automated knitting have transformed the textile industry, enabling faster production, customization, and the creation of intricate designs. As technology continues to advance, automated knitting machines are expected to play a crucial role in the future of textile manufacturing.

How Automated Knitting Machines Work

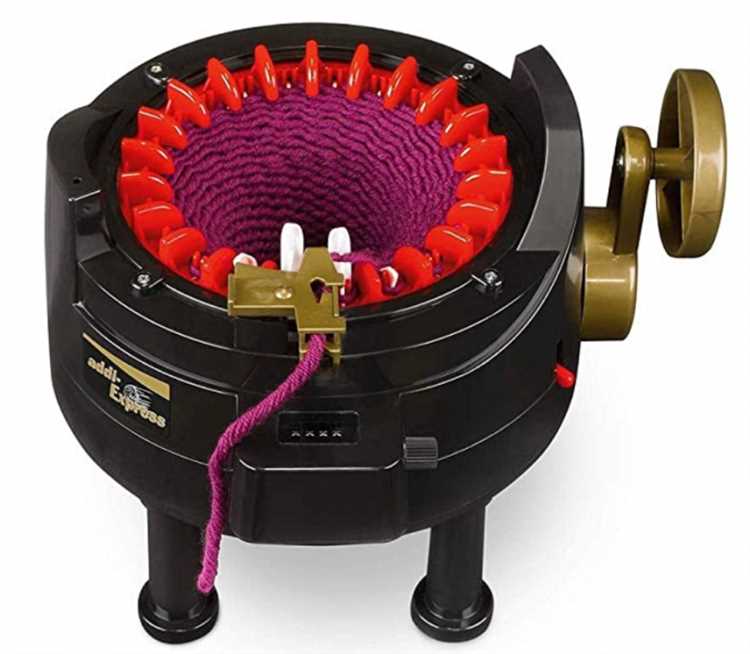

Automated knitting machines, also known as computerized knitting machines, work by using programmable software and electronic controls to guide the knitting process. These machines can create complex patterns and designs with precision and speed, making them an essential tool in the textile industry.

The basic operation of an automated knitting machine involves the following steps:

- Yarn Feeding: The machine is loaded with yarn, which is fed through a series of guides and tensioners to ensure a consistent flow of yarn.

- Needle Selection: The machine has a needle bed with multiple individual needles. The electronic controls determine which needles to select and activate for each stitch, based on the pattern instructions.

- Stitch Formation: The selected needles are lifted or lowered to create loops of yarn. These loops form the stitches, which are held by adjacent needle hooks.

- Fabric Formation: The needle bed moves horizontally or vertically, depending on the machine design, to create the desired fabric structure. This movement of the needle bed determines the density, size, and shape of the knitted fabric.

- Pattern Control: The knitting machine is connected to a computer or programming device, which provides instructions for the desired pattern. The machine reads these instructions and controls the needle selection and fabric formation accordingly.

Automated knitting machines can produce a wide range of knitted products, including garments, accessories, and even three-dimensional objects. They offer numerous advantages over traditional hand knitting, such as increased speed, consistency, and precision.

Additionally, automated knitting machines can easily switch between different patterns and designs, making them highly versatile for batch production or customized orders. The programming software allows designers to create intricate patterns and textures, which can be reproduced with ease.

Overall, automated knitting machines revolutionize the textile industry by combining technology and craftsmanship. They enable faster production, greater design possibilities, and more efficient use of yarn, making them a valuable asset in the modern manufacturing process.

Benefits of Automated Knitting Technology

Automated knitting technology offers numerous benefits in comparison to traditional hand-knitting methods. Here are some of the key advantages:

- Increased Efficiency: Automated knitting machines can produce knitted garments at a much faster rate than humans. This significantly improves productivity and reduces the time required to create knitted products.

- Precision and Consistency: Machines are capable of producing highly precise and consistent knitted fabrics. The automated process ensures that each stitch is formed with accuracy and uniformity, resulting in high-quality finished products.

- Design Versatility: Automated knitting machines offer a wide range of design possibilities, with the ability to create complex patterns, textures, and shapes. This allows for greater creativity and flexibility in the design process.

- Cost Savings: The use of automated knitting technology can help reduce labor costs, as fewer workers are required to produce knitted garments. It also eliminates errors and rework, resulting in cost savings for manufacturers.

- Reduced Waste: Automated knitting technology enables manufacturers to produce garments with minimal waste. The precise control of materials and stitch patterns allows for efficient use of yarn and reduces the amount of scrap or leftover materials.

- Scalability: Automated knitting machines can easily adapt to different production volumes. They can produce small-batch orders as efficiently as large-scale production runs, allowing manufacturers to meet varying customer demands.

In conclusion, automated knitting technology offers numerous benefits, including increased efficiency, precision, versatility, cost savings, reduced waste, and scalability. By harnessing the capabilities of machines, manufacturers can achieve higher productivity, superior quality, and greater design possibilities in the field of knitted textiles.

Limitations and Challenges of Automated Knitting

While automated knitting technology offers numerous advantages, it also has its limitations and presents certain challenges that need to be addressed for widespread adoption and optimal performance. Some of these limitations and challenges include:

- Limited Design Complexity: The current capabilities of automated knitting machines restrict the complexity and intricacy of designs that can be achieved. Fine details and intricate patterns may be difficult to replicate accurately, limiting the possibilities for certain types of knitted products.

- Material and Color Limitations: Automated knitting machines typically work with a limited range of materials, mainly yarns. This limits the variety of fabrics and textures that can be produced. Additionally, the machines may have constraints on the number of colors that can be used in a design, potentially limiting the creativity and aesthetics of the final knitted product.

- Programming and Customization Challenges: Developing the software and algorithms required to control automated knitting machines can be a complex and time-consuming process. Creating intricate patterns or customizing designs may require significant programming expertise, which can pose a challenge to non-technical users.

- Production Time and Cost: While automated knitting technology offers increased efficiency compared to manual knitting, the production time and cost can still be significant. The machines require careful setup, programming, and monitoring, which can result in longer production times and added expenses.

- Machine Size and Portability: Automated knitting machines are often large and bulky, making them less portable and potentially limiting their usage in certain settings. This can be a challenge for small-scale or on-site knitting operations.

- Maintaining Machine Reliability: Automated knitting machines consist of various mechanical and electronic components that can experience wear and tear over time. Ensuring the reliability and durability of these machines, as well as addressing any technical issues that arise, require ongoing maintenance and support.

Addressing these limitations and challenges will involve ongoing research and development efforts to enhance the capabilities, versatility, and user-friendliness of automated knitting technology. Advancements in machine learning, material science, and design software can contribute to overcoming these obstacles and unlock the full potential of automated knitting.

Applications of Automated Knitting in Fashion Industry

The fashion industry has embraced automated knitting technology as a means to revolutionize the design and production process. This innovative technology offers a wide range of applications that cater to the needs of both designers and consumers. Here are some key applications of automated knitting in the fashion industry:

- Customized and personalized garments: Automated knitting machines enable designers to create customized garments that perfectly fit an individual’s measurements. This eliminates the need for standard sizes and allows for personalized fashion experiences.

- Rapid prototyping: Traditional knitting techniques often involve time-consuming manual labor. With automated knitting technology, designers can quickly prototype their ideas, making the design process more efficient and allowing for faster product development cycles.

- Complex and intricate designs: Automated knitting machines have the ability to produce intricate patterns and complex designs that would be difficult to achieve manually. This opens up new creative possibilities for designers, allowing them to experiment with unique textures and patterns.

- Reduced waste: Automated knitting technology allows for precise material usage, minimizing fabric waste. This contributes to a more sustainable and eco-friendly approach to fashion production, reducing the industry’s environmental impact.

- Mass customization: With automated knitting, it becomes possible to produce garments on-demand, eliminating the need for large-scale production and excessive inventory. This enables companies to offer customizable fashion products to consumers without compromising on speed and efficiency.

- Enhanced production efficiency: Automated knitting machines can produce garments at a much faster pace than manual knitting methods. This increased efficiency allows for higher production volumes and shorter turnaround times, meeting the demands of the fast-paced fashion industry.

In conclusion, automated knitting technology has the potential to revolutionize the fashion industry by offering customized, intricate designs, reducing waste, and improving production efficiency. As this technology continues to advance, it promises to redefine the way fashion is designed, produced, and consumed.

Impact of Automated Knitting on Traditional Hand-Knitting

The advent of automated knitting technology has had a significant impact on the traditional practice of hand-knitting. While hand-knitting is a cherished craft that has been passed down through generations, the introduction of machines has revolutionized the industry and changed the dynamics of the market.

Increased Efficiency: One of the biggest impacts of automated knitting technology on traditional hand-knitting is the increase in efficiency. Machines can produce garments at a much faster rate than human knitters, reducing the time and effort required to create a piece. This allows for increased production and faster turnaround times, meeting the demands of a fast-paced fashion industry.

Consistency and Precision: Automated knitting machines are capable of producing consistent and precise stitches, eliminating mistakes that can occur in hand-knitting. This results in improved quality control and ensures that each garment meets the same high standards. Additionally, machines can easily replicate complex patterns and intricate designs, which may be more time-consuming or challenging for hand-knitters.

Cost-effectiveness: The use of automated knitting technology has made it more cost-effective to produce knitted garments. By reducing labor costs and increasing production efficiency, manufacturers can offer their products at competitive prices. This has both positive and negative implications for hand-knitters. On one hand, it may lead to a decline in demand for handmade items as consumers opt for more affordable machine-knitted alternatives. On the other hand, it may create opportunities for crafters to focus on unique, artisanal pieces that cannot be replicated by machines.

Innovation and Creativity: While automated knitting machines offer efficiency and precision, they may be limited in terms of creativity and customization. Hand-knitting allows for experimentation with different yarns, textures, and patterns, giving artisans greater control over the final product. Traditional hand-knitters can continue to thrive by offering bespoke items that cater to niche markets or those seeking a more personalized touch.

Skill Preservation: It is essential to recognize the impact that automated knitting technology may have on the preservation of hand-knitting skills. As the industry leans more towards automation, there is a risk that traditional knitting techniques and expertise may be lost. It is crucial for enthusiasts and organizations to promote and preserve hand-knitting as a valued craft, ensuring that future generations continue to appreciate and practice this cherished tradition.

| Pros | Cons |

|---|---|

|

|

Future Prospects of Automated Knitting Technology

Automated knitting technology has made significant advancements in recent years, and its future prospects are promising. With the ability to quickly and accurately produce knitted fabrics, machines have revolutionized the textile industry.

Increased Efficiency: One of the key advantages of automated knitting technology is its ability to significantly improve efficiency in the production process. Machines can knit at a much faster rate compared to manual knitting, leading to increased output and reduced labor costs. This increased efficiency allows manufacturers to meet growing demands and stay competitive in the market.

Customization and Design: Automated knitting technology also offers exciting possibilities for customization and design. With the use of computer programming, machines can create complex patterns and designs that were once only achievable through manual labor. This opens up a world of creative opportunities for designers and allows for unique and personalized garments to be produced on a larger scale.

Sustainability: As sustainability becomes an increasingly important factor in the textile industry, automated knitting technology has the potential to contribute to a more eco-friendly future. Machines can be programmed to optimize yarn usage, minimize waste, and reduce overall energy consumption. This reduces the environmental impact associated with traditional knitting processes and supports the industry’s shift towards sustainability.

Integration with Other Technologies: The future prospects of automated knitting technology also involve its integration with other emerging technologies. For example, the combination of automated knitting machines with 3D printing technology could enable the creation of complex and customized garments with intricate textures and structures. Additionally, the use of smart textiles and sensors can be incorporated into knitted fabrics, unlocking possibilities for wearable technology and advanced functionalities.

Automation and Accessibility: Automated knitting technology has the potential to make the production of knitted garments more accessible. As machines become more affordable and user-friendly, smaller businesses and independent designers can take advantage of automated knitting technology to produce high-quality garments at a lower cost. This democratization of the technology could lead to a more diverse and innovative fashion industry.

Research and Development: The future prospects of automated knitting technology rely heavily on ongoing research and development. Continued advancements in machine learning, materials science, and robotics will further enhance the capabilities of automated knitting machines. This ongoing innovation will result in even more efficient and versatile machines with the ability to produce a wider range of knitted products.

In conclusion, the future prospects of automated knitting technology are exciting and full of potential. Increased efficiency, customization and design possibilities, sustainability, integration with other technologies, automation and accessibility, and ongoing research and development are all factors that contribute to the bright future of automated knitting technology in the textile industry.

FAQ:

What is automated knitting technology?

Automated knitting technology refers to the use of machines or computerized systems to perform the process of knitting fabric or garments. It involves the use of programmed patterns or designs to guide the knitting machine and automate the knitting process.

Can machines knit complex patterns?

Yes, machines equipped with automated knitting technology can knit complex patterns. With the use of programmed designs and patterns, the machines can create intricate and detailed patterns in the knitted fabric or garment.

How fast can machines knit?

The speed at which machines can knit depends on several factors, including the type of machine, the complexity of the pattern, and the desired quality of the output. However, in general, automated knitting machines are capable of knitting at a much faster speed compared to traditional hand knitting techniques, which makes them more efficient for mass production.

What are the advantages of automated knitting technology?

Automated knitting technology offers several advantages. It allows for faster production, higher precision and accuracy in creating patterns, consistency in the output, and the ability to handle complex and intricate designs. It also reduces the need for manual labor, making the process more cost-effective.

Can machines knit different types of yarn?

Yes, machines equipped with automated knitting technology can knit different types of yarn. The machines can be adjusted and programmed to work with various yarn weights and fibers, allowing for flexibility in the selection of materials for knitted products.

Are there any limitations to automated knitting technology?

Although automated knitting technology has many advantages, it also has some limitations. The complexity of the pattern and design that can be achieved is limited to the capabilities of the machine and the software used. Additionally, automated knitting machines may not be suitable for delicate or highly intricate hand-knitted designs that require a more tactile and artful touch.

Can automated knitting technology replace hand knitting?

Automated knitting technology can never fully replace hand knitting, as hand knitting offers a unique and artistic touch that machines cannot replicate. Hand knitting allows for more creativity and customization of designs and provides a more personal and intimate connection with the knitted product. However, automated knitting technology can be a valuable tool for mass production and achieving consistent and precise results.