Glazing pottery can be a delicate process that requires precision and attention to detail. However, even when following all the steps correctly, there are times when the glaze just doesn’t stick to the bisque. This can be frustrating for potters, but don’t worry, there are several reasons why this might be happening and solutions to help you troubleshoot the issue.

1. Dust or Oil

One common reason why glaze doesn’t stick to bisque is the presence of dust or oil on the surface. Before applying glaze, always make sure that your bisque is clean and free from any contaminants. Wipe it with a clean cloth or use compressed air to remove any dust particles or oily residue.

2. Insufficient Drying Time

If you apply glaze to your bisque before it is fully dried, the glaze may not adhere properly. Allow your bisque to dry completely before applying glaze. This will ensure that the glaze has the best chance of sticking to the surface.

3. Poor Glaze Application

The way you apply glaze can also affect its ability to stick to bisque. Be sure to apply an even coat of glaze, using a brush or a spray gun. Avoid applying the glaze too thickly, as this can cause it to run and not adhere properly to the bisque.

4. Bisque too Smooth

If your bisque is too smooth, the glaze may have a difficult time adhering to the surface. To improve adherence, consider roughening the bisque by sanding or using a wire brush to create a slightly textured surface for the glaze to grip onto.

5. Incorrect Firing Temperature

The firing temperature of your kiln can also affect how well glaze sticks to bisque. If the temperature is too low, the glaze may not fully melt and bond with the bisque. Make sure you are firing your kiln to the correct temperature for the glaze you are using.

“Glazing pottery can be a delicate process that requires precision and attention to detail. However, even when following all the steps correctly, there are times when the glaze just doesn’t stick to the bisque.”

6. Incompatible Glaze and Bisque

Some glazes may not be compatible with certain types of bisque. It’s important to choose glazes that are specifically formulated for the type of clay body you are using. Using an incompatible glaze can result in poor adhesion and a lack of stickiness to the bisque.

7. Contaminated Glaze

Contaminated glaze can also cause issues with adherence. Make sure your glaze is properly mixed and doesn’t contain any foreign substances or impurities. Strain your glaze before applying it to ensure a smooth and clean application.

8. Glaze Shrinkage

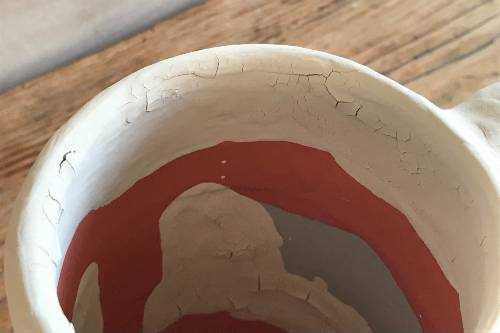

Some glazes may shrink as they dry and during firing, which can cause them to crack and separate from the bisque surface. Make sure you are using a glaze that has similar shrinkage properties to your bisque to ensure a good bond between the two.

9. Improper Firing Schedule

The firing schedule you use in your kiln can also affect glaze adherence. Make sure you are following the recommended firing schedule for the glaze you are using. Incorrect firing rates or holding times can result in poor adhesion and glaze not sticking to the bisque.

By understanding and addressing these common issues, you can troubleshoot and improve the adhesion of glaze to your bisque. Don’t be discouraged if your glaze isn’t sticking initially – with some adjustments and practice, you’ll be able to achieve the desired results on your pottery.

Common Glaze Problems: Why Your Glaze is Not Sticking to Your Bisque

When working with ceramics, one of the most frustrating problems you may encounter is glaze not sticking to your bisque. This can lead to unsightly finishes, wasted materials, and a lot of frustration. Fortunately, many common glaze problems can be easily resolved with a little troubleshooting. Here are some reasons why your glaze might not be sticking to your bisque:

- Contamination: Ensure that your bisqueware is clean before applying glaze. Any dirt, dust, or oils can prevent the glaze from adhering properly. Clean your bisqueware with a damp sponge or cloth before glazing.

- Inadequate Drying Time: If your bisqueware is not completely dry before applying glaze, the moisture can interfere with the glaze application. Allow your bisqueware to dry thoroughly before glazing.

- Incompatible Glaze and Bisque: Some glazes and bisques are not compatible with each other. Make sure you are using a glaze that is specifically formulated to work with your type of bisque. Consult the manufacturer’s guidelines or test the compatibility of your glaze and bisque before applying.

- Inconsistent Glaze Application: Apply your glaze evenly and consistently to ensure proper adhesion. Avoid thin or uneven glaze layers, as they may not adhere well to the bisque. Use a glaze brush or spray gun for even application.

- Insufficient Glaze Thickness: A thin glaze layer may not bond well with the bisque. Apply multiple coats of glaze to achieve the desired thickness. Allow each coat to dry before applying the next.

- High-Fire Glaze on Low-Fire Bisque: Using a high-fire glaze on low-fire bisque can result in poor adhesion. Make sure you are using glaze and bisque that have compatible firing temperatures.

- Glaze Not Fired to Maturity: If your glaze has not been fired to its recommended maturity temperature, it may not adhere properly to the bisque. Follow the firing instructions provided by the glaze manufacturer.

- Glaze Application on Greenware: Glazing greenware (unfired clay) can lead to poor adhesion. It is best to bisque-fire your pottery before applying glaze.

- Improper Kiln Firing: The firing process plays a crucial role in glaze adhesion. Incorrect firing temperatures or schedules can affect the glaze’s ability to adhere to the bisque. Make sure you are following the recommended firing instructions for your glaze and bisque.

By addressing these common issues, you can improve the adhesion of your glaze to your bisque. Troubleshooting glaze problems may require some experimentation and adjustment, but with a little patience and practice, you can achieve the desired results in your ceramic work.

Insufficient Cleaning: The Importance of Properly Cleaning Your Bisque

One of the common reasons why glaze may not stick to your bisqueware is insufficient cleaning. Properly cleaning your bisque before applying glaze is essential to ensure that the glaze adheres well to the surface.

When bisqueware is fired, it can accumulate dust, oils, and other contaminants that can hinder the glaze’s ability to adhere properly. Cleaning the bisque thoroughly removes these impurities, creating a clean surface for the glaze to bond with.

Here are some key points to consider when cleaning your bisque:

- Remove dust: Use a soft brush or compressed air to remove any dust particles that may have settled on the bisqueware. Pay close attention to crevices and hard-to-reach areas.

- Wash with mild detergent: Use a mild detergent and warm water to wash the bisque. Gently scrub the surface with a sponge or soft cloth to remove any remaining dirt or oils. Make sure to rinse thoroughly to remove any soap residue.

- Dry completely: After washing, allow the bisque to dry completely before proceeding with glazing. Moisture can interfere with the glaze’s ability to adhere properly. You can use a clean towel or air dry the bisqueware.

- Avoid touching the surface: When handling the bisqueware, try to avoid touching the surface with bare hands as oils from your skin can transfer to the bisque. If necessary, wear gloves or use a clean cloth to handle the bisqueware.

By taking these cleaning steps, you are ensuring that your bisqueware is ready to accept glaze. Proper cleaning not only helps the glaze adhere better, but it also promotes more consistent and satisfactory results in the firing process.

Bisque Firing Issues: Understanding the Impact of Bisque Firing on Glaze Adhesion

When it comes to glazing ceramics, one of the most important steps is the bisque firing process. Bisque firing transforms raw clay into a porous and hardened state, preparing it to receive glaze. However, if not done properly, bisque firing can cause issues with glaze adhesion. Here are some common bisque firing issues and how they can impact the adhesion of the glaze:

1. Underfiring: Underfiring bisqueware can result in a low density and poorly vitrified clay body. This can create a weak surface that may not provide enough support for the glaze, leading to poor adhesion.

2. Overfiring: Overfiring bisqueware can result in excessive vitrification and a glassy surface. This can make it difficult for the glaze to adhere to the clay body, leading to poor adhesion and potential peeling or flaking.

3. Uneven Firing: Uneven firing can occur if the kiln temperature is not distributed evenly, resulting in variations in the degree of vitrification across the surface of the bisqueware. This can lead to inconsistent glaze adhesion, with some areas sticking well and others not adhering properly.

4. Insufficient Bisque Firing Time: Insufficient bisque firing time can result in an under-vitrified clay body. The clay may still contain impurities or trapped moisture, which can interfere with glaze adhesion.

5. Contaminated Bisqueware: Contaminants on the surface of the bisqueware, such as dust, oils, or other substances, can create a barrier between the glaze and the clay body. This can prevent the glaze from adhering properly and may result in poor adhesion.

6. Rough Bisque Surface: A rough or uneven bisque surface can make it difficult for the glaze to adhere uniformly. The glaze may not flow evenly over the surface, resulting in an uneven glaze coating and potential adhesion issues.

7. Improper Kiln Ventilation: Inadequate kiln ventilation during bisque firing can lead to the production of carbon or other gases, which can affect the glaze adhesion. These gases may cause blisters, pinholes, or other surface imperfections that can interfere with glaze adhesion.

8. Irregular Shrinkage: If the clay body shrinks unevenly during bisque firing, it can create stresses within the structure of the ceramic piece. These stresses can cause the glaze to crack or craze, resulting in poor adhesion.

9. Insufficient Cleaning: Proper cleaning of bisqueware before glazing is essential to ensure good adhesion. Any residual debris or contaminants left on the surface can prevent the glaze from adhering properly.

Understanding the impact of bisque firing on glaze adhesion is crucial for achieving successful and durable glazed ceramics. By addressing these common bisque firing issues, you can improve the adhesion of your glaze and create stunning ceramic pieces.

Inadequate Glaze Thickness: How the Thickness of Your Glaze Can Affect Adhesion

One of the common reasons why a glaze may not stick properly to your bisqueware is due to inadequate glaze thickness. It is important to have a sufficient amount of glaze on your pottery in order to ensure proper adhesion.

Here are a few reasons why inadequate glaze thickness can affect adhesion:

- Insufficient Coverage: If your glaze layer is too thin, it may not completely cover the surface of your bisqueware. This can lead to patchy or uneven glaze coverage, resulting in areas where the glaze does not adhere properly.

- Poor Adhesion: A thin layer of glaze may not have enough surface area to adhere properly to the bisqueware. This can cause the glaze to easily chip or peel off during firing or regular use.

- Blistering and Pinholing: Inadequate glaze thickness can also lead to issues such as blistering and pinholing. When the glaze layer is too thin, it may not melt and flow properly during firing, resulting in the formation of bubbles or tiny pinholes on the surface of the pottery.

To ensure adequate glaze thickness and improve adhesion, consider the following tips:

- Apply Multiple Coats: Applying multiple coats of glaze can help to build up a thicker layer and ensure better coverage. Allow each coat to dry before applying the next one, and make sure to follow the manufacturer’s recommendations for drying time between coats.

- Smooth and Even Application: Use a brush or other application tool to apply the glaze smoothly and evenly. Avoid leaving thick or thin spots, as this can affect adhesion and create uneven results.

- Choose the Right Consistency: Make sure that your glaze is mixed to the proper consistency. If it is too thick, it may be difficult to apply a smooth and even coat. If it is too thin, it may not provide adequate coverage or adhere properly to the bisqueware.

By ensuring that your glaze has the proper thickness, you can greatly improve adhesion and achieve the desired results on your glazed pottery.

Glaze Compatibility: Ensuring Your Glaze is Compatible with Your Bisque

Glaze compatibility refers to the ability of a glaze to adhere properly to a bisque during the firing process. If your glaze is not sticking to your bisque, it could be due to compatibility issues. Here are some factors to consider when ensuring your glaze is compatible with your bisque.

- Body composition: The composition of your bisque body can influence the compatibility of your glaze. Different clay bodies have different properties and may require specific glaze formulas to achieve good adherence.

- Bisque firing temperature: The temperature at which you bisque fire your pottery can affect glaze compatibility. It is important to fire your bisque to the recommended temperature range for the specific glaze you plan to use.

- Glaze fit: The fit between the glaze and the bisque is crucial for proper adhesion. If the glaze expands or contracts significantly more than the bisque during firing, it can cause the glaze to crack or peel off. Consider using glazes with similar coefficients of expansion to your bisque.

- Grog content: The presence of grog or other aggregates in the bisque body can create a rough surface that might not allow the glaze to adhere properly. Ensure that your bisque has a smooth surface for better glaze adhesion.

- Dust and contamination: Dust or other contaminants on the bisque surface can prevent the glaze from adhering properly. Make sure to clean your bisque thoroughly before applying glaze.

- Glaze application: Proper glaze application techniques can also affect compatibility. Ensure that you apply the glaze evenly and in the recommended thickness for optimal adherence.

- Glaze formulation: The formulation of your glaze can impact its compatibility with the bisque. Use glazes that are specifically designed for the type of bisque you are using.

- Firing schedule: The firing schedule, including the temperature ramp rate and hold times, can influence glaze adherence. Follow the recommended firing schedule for the glaze to ensure compatibility.

- Firing atmosphere: The atmosphere in the kiln during firing can also affect glaze compatibility. Different glazes may require specific firing atmospheres, such as oxidation or reduction, to achieve proper adherence.

By considering these factors and properly testing your glazes on your specific bisque body, you can ensure better glaze compatibility and improve the adhesion of your glazes.

Incorrect Glaze Application: Avoiding Mistakes in Applying Glaze to Your Bisque

Properly applying glaze to your bisque-fired pottery is crucial for achieving a beautiful and functional finished piece. However, if your glaze is not sticking to your bisque, there may be some mistakes in your glaze application. Here are some common errors to avoid:

- Not Cleaning the Bisque: Before glazing, make sure to thoroughly clean your bisque to remove any dust, dirt, or oils. This can be done by wiping it down with a damp sponge or rinsing it with water.

- Applying Glaze too Thick or Thin: It’s essential to apply glaze evenly to avoid clumping or thin patches. Use a brush or dip method to apply a consistent coating of glaze to your bisque.

- Not Stirring the Glaze: Glazes can settle and separate over time. Before applying glaze, stir it well to ensure that the ingredients are thoroughly mixed and evenly distributed.

- Glazing Over Dust or Contaminants: Any dust or contaminants on the bisque surface can prevent glaze from adhering properly. Make sure your workspace is clean and brush off any particles before glazing.

- Not Allowing Glaze to Dry: After applying glaze, allow it to dry completely before firing. If the glaze is not dry, it may not stick or may crack during firing.

- Using Incompatible Glazes: Some glazes may not adhere properly if they are not compatible with the bisque or other glazes. Check the compatibility of your glazes or consult a glaze compatibility chart before applying.

- Applying Glaze to Unfired Bisque: Glaze should only be applied to bisque-fired pottery. Applying it to unfired clay can cause the glaze to crack or peel off during firing.

- Insufficient Glaze Layers: Applying too thin of a glaze layer may result in a patchy or uneven finish. Apply multiple layers of glaze, allowing each layer to dry before applying the next, to achieve a smoother and more consistent appearance.

- Using Contaminated Tools: Make sure your brushes or dipping tools are clean and free from previous glazes or contaminants. Contaminated tools can introduce impurities into the glaze and prevent it from adhering properly.

By avoiding these mistakes and following proper glaze application techniques, you can ensure that your glaze will stick to your bisque and create stunning finished pottery pieces.

Firing Technique: Optimizing Firing Conditions for Glaze to Stick to Your Bisque

Firing your bisque correctly is crucial for ensuring that the glaze adheres properly to the surface of your pottery. Here are some tips for optimizing your firing technique to achieve the best results:

- Bisque Firing Temperature: Make sure you are firing your bisque to the appropriate temperature. Under-firing can result in a porous surface that does not hold the glaze well, while over-firing can cause the glaze to run off the pottery.

- Ramp and Soak: Pay attention to the rate at which you are heating and cooling your pottery. A slow ramp rate and soak at peak temperature can help in the even distribution of heat, allowing the glaze to bond properly with the bisque.

- Even Heating: Ensure that the heat distribution inside your kiln is even. Uneven heating can cause variations in the glaze application, leading to irregularities in how it adheres to the bisque.

- Kiln Ventilation: Proper ventilation inside the kiln is important to allow any moisture or gases to escape during firing. Excess moisture can hinder the glaze’s ability to attach to the bisque surface.

- Glaze Thickness: Apply glaze in a consistent and appropriate thickness. Too thin of a layer may not adhere well to the bisque, while too thick of a layer can lead to excessive running and pooling.

- Glaze Application Techniques: Explore different glaze application techniques such as dipping, brushing, spraying, or pouring, to find the method that works best for the specific glaze and bisque you are using.

- Glaze Compatibility: Ensure that the glaze you are using is compatible with the type of bisque you are firing. Different clay bodies require different glaze formulations for optimal adherence.

- Glaze Uniformity: Check for any inconsistencies in the glaze application, such as areas with too much or too little glaze. These variations can affect how well the glaze sticks to the bisque.

- Cool Down Process: Pay attention to the cooling process after the firing. Abrupt cooling or temperature fluctuations can cause stress on the glaze, leading to poor adhesion to the bisque.

By optimizing your firing technique and following these tips, you can maximize the chances of your glaze adhering properly to your bisque, resulting in beautiful and durable pottery pieces.

Contamination or Impurities: Identifying and Addressing Contamination Issues in Your Glaze

In pottery and ceramics, one of the common issues that artists face is glaze not sticking properly to the bisqueware. While there can be various reasons behind this problem, contamination or impurities in the glaze can be a major culprit. This section will discuss how to identify and address contamination issues in your glaze.

1. Contamination Sources:

Contamination in your glaze can come from various sources, including:

- Clay particles: If there are clay particles in your glaze, they can prevent proper adhesion and cause the glaze to peel off.

- Dust and debris: Dust particles or debris can mix with your glaze and create rough surfaces or cause uneven application.

- Chemical impurities: Some chemicals used in glazes, such as feldspar or oxides, can contain impurities that affect the glaze’s performance.

- Contaminated tools: Tools used for mixing or applying glaze can introduce contaminants if not properly cleaned.

2. Visual Inspection:

Inspect your glaze visually to identify any visible signs of contamination. Look for specks, streaks, or discolored patches that might indicate impurities in the glaze.

3. Sieving:

If you suspect contamination in your glaze, sieve it to remove any foreign particles. Use a fine mesh or sieve to strain out clay particles, dust, or other impurities. This will help improve the consistency and smoothness of your glaze.

4. Clumping or Separation:

If your glaze is clumping or separating, it might indicate contamination. In such cases, you can try remixing the glaze thoroughly or consider discarding it if the issue persists.

5. Cleanliness:

Maintain a clean workspace and use clean tools to minimize the chances of contamination. Regularly clean your brushes, buckets, and other glaze application tools to ensure they are free from any residual contaminants.

6. Testing and Adjusting:

Perform test firings and glaze applications to identify any recurring issues with glaze adhesion. Adjust the formulation, sieving process, or application techniques based on the results to address contamination problems.

7. Glaze Recipes:

Review and modify your glaze recipe if contamination issues persist. Ensure that all ingredients used in the glaze are of high quality and free from impurities. Experiment with alternative materials or suppliers to find the best combination.

8. Raw Material Selection:

Choose raw materials for your glaze carefully. Opt for materials that are known for their purity and reliability. Research and consult experienced potters to gather information about the quality and reliability of different raw materials.

9. Professional Assistance:

If you continue to face contamination issues despite your best efforts, seeking guidance from a professional pottery teacher or expert can be helpful. They can provide valuable advice on troubleshooting the problem and suggest alternative approaches.

By taking these steps to identify and address contamination problems in your glaze, you can improve the quality and consistency of your pottery pieces. Remember that troubleshooting glaze issues is a continuous learning process, and persistence and experimentation are key to achieving the desired results.

Glaze Defects: Understanding Glaze Defects and Their Impact on Adhesion

Glaze defects can greatly impact the adhesion of glaze to bisqueware, resulting in a glaze that does not stick properly. It’s important to understand these defects and how they can affect the final outcome of your ceramic piece. Here are some common glaze defects and their impact on adhesion:

- Crawling: Crawling occurs when the glaze retracts and forms cracks or bare spots during firing. This defect can prevent the glaze from adhering properly to the bisqueware and create areas where the glaze doesn’t stick.

- Pinholing: Pinholing is the formation of tiny holes or bubbles in the glaze surface. These holes can act as barriers, preventing the glaze from adhering to the bisqueware. Pinholes can also lead to a weak bond between the glaze and the ceramic surface.

- Blistering: Blistering is the formation of bubbles or blisters on the glaze surface during firing. Like pinholes, blisters can create barriers that prevent the glaze from adhering properly to the bisqueware.

- Crazing: Crazing refers to the formation of fine cracks in the glaze surface. Although the cracks may not be visible to the naked eye, they can still affect the adhesion of the glaze. Cracks can provide pathways for moisture to penetrate the glaze layer, weakening its bond with the bisqueware.

- Peeling: Peeling occurs when the glaze layer starts to detach from the ceramic surface. This can happen due to poor adhesion caused by any of the above defects. Peeling can result in uneven coverage and loss of glaze in some areas.

To achieve better adhesion of your glaze, it’s important to identify and address these glaze defects. Here are some steps you can take to prevent or minimize these defects:

- Ensure proper clay body and glaze compatibility.

- Follow recommended firing schedules and temperatures.

- Apply glaze in even and consistent thickness.

- Avoid applying glaze too thick or too thin.

- Allow sufficient drying time before firing.

- Avoid contamination of glazes with foreign materials.

- Consider using glaze additives to address specific defects.

By understanding these common glaze defects and following proper ceramic techniques, you can achieve better adhesion of your glaze to bisqueware and create beautiful ceramic pieces.

FAQ:

Why is my glaze not sticking to my bisque?

There could be several reasons why your glaze is not sticking to your bisque. Some possible reasons could include the bisque being too dusty, the bisque not being properly cleaned before glazing, the glaze being too thick or too thin, or the glaze not being properly applied to the bisque.

How can I prevent my bisque from being too dusty?

To prevent your bisque from being too dusty, make sure to properly clean and wipe down your bisque before glazing. Use a damp sponge or cloth to remove any dust or dirt particles that may be present. Additionally, storing your bisque in a clean and dust-free environment can help prevent dust accumulation.

What should I use to clean my bisque before glazing?

You can use a damp sponge or cloth to clean your bisque before glazing. Make sure to remove any dust, dirt, or debris that may be present on the surface of the bisque. Avoid using any harsh chemicals or abrasive materials that may damage the surface of the bisque.

How can I tell if my glaze is too thick or too thin?

To determine if your glaze is too thick or too thin, you can perform a simple test. Dip a brush into the glaze and then remove it. If the glaze drips off the brush very quickly and in large amounts, it may be too thin. If the glaze is clumpy and does not adhere well to the brush, it may be too thick. Adjust the consistency of the glaze by adding water or glaze powder accordingly.

What can I do if my glaze is too thick?

If your glaze is too thick, you can try adding a small amount of water to thin it out. Pour the glaze into a separate container and gradually add water while stirring or shaking. Mix well until you reach the desired consistency. Make sure to test the thinned glaze on a test piece before applying it to your bisque.

What can I do if my glaze is too thin?

If your glaze is too thin, you can try adding more glaze powder to thicken it up. Gradually add small amounts of glaze powder to the thin glaze while stirring or shaking. Mix well until you reach the desired consistency. Make sure to test the thickened glaze on a test piece before applying it to your bisque.

How can I ensure that my glaze is properly applied to the bisque?

To ensure that your glaze is properly applied to the bisque, make sure to use even and smooth brush strokes. Apply the glaze in a thin and consistent layer, making sure to cover the entire surface of the bisque. Avoid applying glaze too thickly or too thinly, as this can affect the adhesion of the glaze to the bisque. Allow the glaze to dry completely before firing.